The laboratory accurately screens, filters and detects the particle size structure, liquid solid content and amount of debris of granular and powder materials. This article will mainly explain the structure of sieve shaker machin.

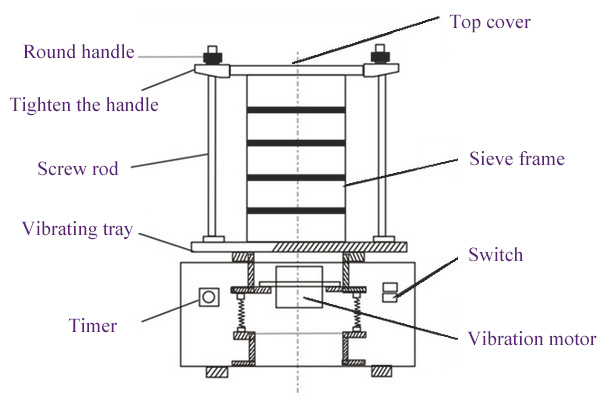

The upper part of the Sieve shaker machine is composed of fixed brass nut, pressure plate, screen cover, screen frame, middle screen frame, screen bottom, isometric adjustment rod and so on. All parts are made of high-quality SUS304 stainless steel. Flexible, high interchangeability

Screen frame: made of SUS304 (0Cr18ni9) stainless steel stretched and polished, wall thickness 0.6mm, surface light can be seen, the overall shape is sturdy and durable, non-magnetic, screen and screen frame are fixed by soldering, will not relax, and can withstand 300 degrees The following high temperature.

Vibrating body: 10mm vibrating body round turning processing, real material, more standard abbreviation.

Time relay: 0-99 minutes timing function, you can freely control the screening time.

Sieve shaker machine uses YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits the vibration through the vibrating plate to the screen frame on the upper part of the vibrating plate. The material particles smaller than the sieve aperture are sieved to the lower sieve frame, and the sieve shaker machine is screened in this way so that only materials of the same size are left in each layer of the sieve shaker machine. The materials can be very effective for filtering, grading and screening purposes.

The above content is an introduction to the structure of the sieve shaker machine. For more detailed information, please leave a message or send an email to sale@xxdahan.com.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.