sand test sieve

sand test sieve sand gradation sieve

sand gradation sieve sand sieve analysis

sand sieve analysis sieve test for sand

sieve test for sand sand sieve machine

sand sieve machine

For determining particle size distribution of sand, aggregates, soil

![]()

![]()

![]()

Price:$24.00 - $26.00/Piece

Consult now and enjoy a 10% discount

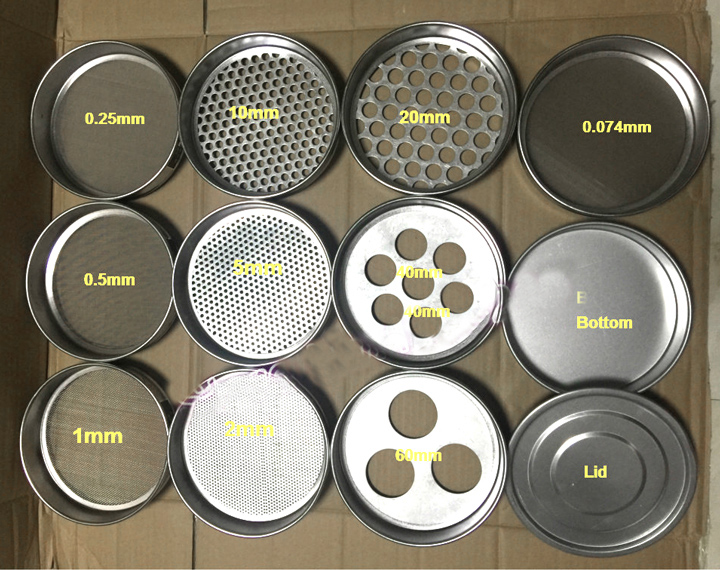

Diameter: 200mm, 300mm

Height: 3.5cm, 5cm, 6cm, 7.5cm, 8cm, 10cm etc.

Aperture size: perforated plate for aperture size bigger than 1.18mm , woven mesh for aperture size smaller than 1.18mm

Specification: 0.075mm, 0.15mm, 0.6mm, 1.18mm, 2.6mm, 4.75mm, 9.5mm

Material: Brass, stainless steel, alumium, pvc coated,etc.

Weight: 0.2-0.5Kg

Application: Determination of the percentage of the content of each particle group in the dry soil to the total mass of the soil, the particle size, gradation and particle group content of the soil, etc.

Commitment:

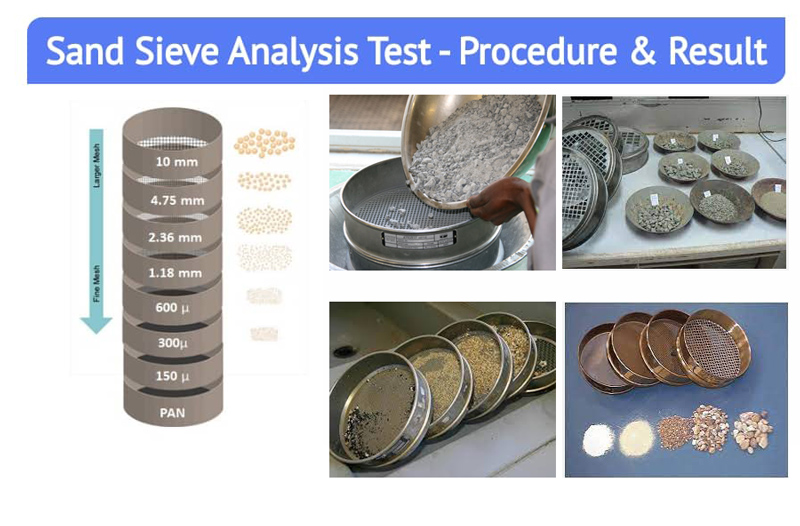

Sand test sieve is a national standard test sieve used in the laboratory to analyze and process the particle size of stones. Usually, the common mesh sizes are 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm and other particle size ranges for analysis and testing. Sand test sieve usually uses a square hole punching plate screen structure. The equipment standard is also determined by the national standard. According to the laboratory requirements, the diameter is usually 300mm, 200mm, and a maximum of 8 layers of standard screen frames can be installed at one time. Stone is divided into gravel, very coarse sand, coarse sand, medium sand, fine sand, very fine sand, and fines (9.50, 4.75, 2.36, 1.18, 0.6, 0.3, 0.15, 0.075mm).

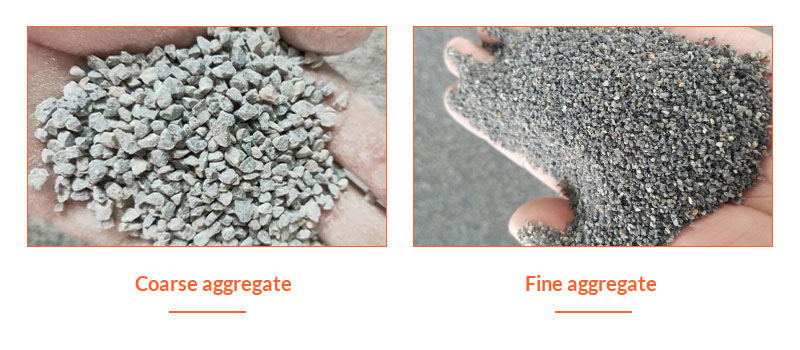

Coarse and fine aggregate

According to the magnitude of particle size, we can divide materials into coarse and fine styles. Different functions of particle sizes have different boundary dimensions of the coarse and fine aggregates.

The particle size larger than the boundary size is coarse aggregates. The rest is fine aggregates.

Cement concrete: The boundary size is 4.75 millimeters. The aggregates with a particle size greater than 4.75 mm are coarse aggregates (stone). Those smaller than 4.75 mm and greater than 0.15mm are fine aggregates (sand);

Bituminous mixture: The boundary size is 2.36 millimeters;

Gravel and sand: The boundary size is 2 millimeters. The aggregates with a particle size greater than 2 mm are gravel (stone); those smaller than 2 millimeters are sand. Gravel sand refers to sand in which the content of gravel grain in sandstone accounts for 25%-50% of the total mass (2mm).

Qualified fine aggregates have good grades of sand, including fineness modulus, firmness and mud content. Fineness modulus can measure the aggregate quality, as it affects the concrete workability, strength and impermeability.

Fineness Modulus

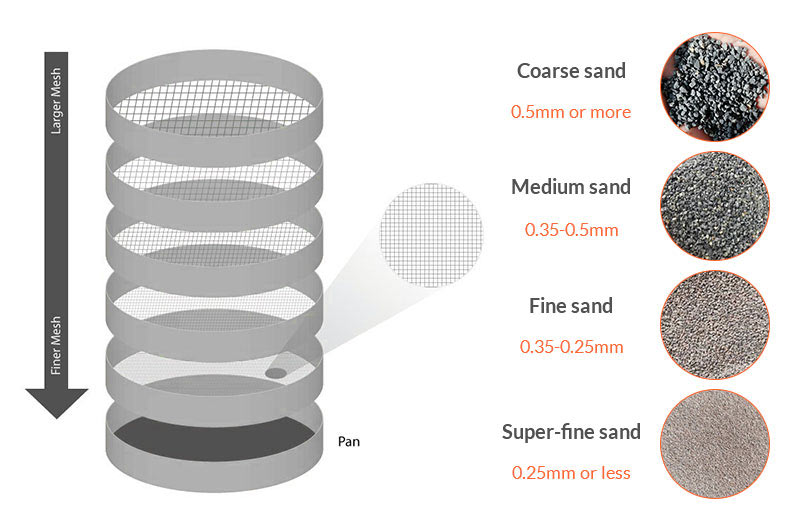

Fineness modulus (F.M.) can reflect the particle size of aggregates. The larger the fineness modulus, the thicker the fine aggregate. It is calculated by the sieving analysis with standard IS sieves.

sieving analysis allows materials to pass through a series of sieves with gradually decreasing mesh sizes to evaluate the particle size distribution.

Fineness modulus formula:

Cumulative % weight retained = (commutative weight retained / total weight) * 100%

F.M. = (total cumulative % weight retained) / 100

The fineness modulus of sand is divided into 4 levels. (Sand size in mm)

Coarse sand size: Its fineness modulus is 3.1-3.7, and the average particle size is 0.5mm or more;

Medium sand grain size: Its fineness modulus is 2.3-3.0, and the average particle size is 0.35-0.5mm;

Fine sand size: Its fineness modulus is 1.6-2.2, and the average particle size is 0.25-0.35mm;

Super-fine sand size: Its fineness modulus is 0.7-1.5, and the average particle size is 0.25mm or less.

The fineness modulus of cement ranges from 1.6 to 3.7, preferably medium or coarse sand plus a small amount of fine sand in a ratio of 4:1. For the particle size of cement, about 95% of cement is within 45 microns. And the average particle size is 15 microns.

During sieving the sample is subjected to horizontal or vertical movement in accordance with the chosen method. This causes a relative movement between the particles and the sieve; depending on their size the individual particles either pass through the sieve mesh or are retained on the sieve surface.Make each test sieve only the material of the same particle size, realize the separation of different particle sizes, and determine the particle size composition of the material

| Sand Test Sieve Specification | ||

| Sieve Material | Brass, SS304/316/316L,galvanized,etc. | |

| Sieve Diameter | 3" 6" 8" 10" 12" 200mm 300mm | |

| Frame | Material | Brass , stainless steel, alumium, pvc coated,etc. |

| Height (full) | 3.5cm,5cm, 6cm, 7.5cm, 8cm, 10cm etc. | |

| Aperture shape | Square | |

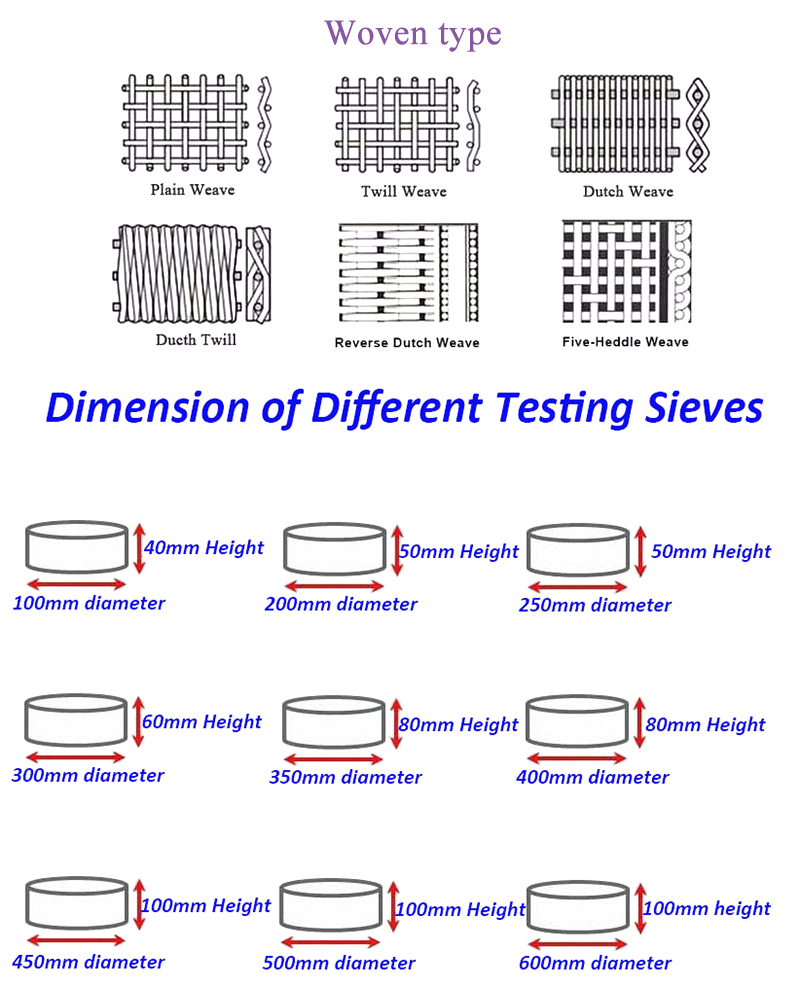

| Weave Style | plain,twill,dutch,etc. | |

| Mesh opening | 1-600mesh | |

| Aperture | 0.01-1mm | |

| Certificate | ASTM IOS SGS | |

Sand test sieve is divided into conventional soil analysis sieve, gravel soil sieve, sand special sieve, cement soil sieve, asphalt soil sieve, coal sample analysis sieve, metallurgical ore inspection sieve, etc.

| NO. | Types | Specification |

|

Standard sand screen (φ300, 7 pcs/set + bottom cover) | 9.50、4.75、2.36、1.18、600um、300um、150um |

|

Standard stone sieve (φ300 12 pcs/set + bottom cover) | 2.36、4.75、9.50、16.0、19.0、26.5、31.5、37.5、53.0、63.0、0.75、90.0mm |

|

Pavement base aggregate screen (φ200, 300, 11 pcs/set + bottom cover) | 0.075、0.25、0.5、1、2、5、10、20、30、40、50 |

|

Bitumen Aggregate Square Hole Screen | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16、19、26.5、31.5、53mm0 |

|

Standard square hole screen (φ200×50mm 6pcs/set) | 4.75、9.5、13.2、16、19、26.5、31.5、37.5、53mm ; |

| 0.075、0.15、0.3、0.6、1.18、2.36 | ||

|

Frame punching sand screen (casting screen) φ200 (11 pcs/set) | 3.35、1.7、0.85、0.6、0.425、0.3、0.212、0.15、0.106、0.075、0.53mm |

|

Pavement square hole aggregate screen | 80、60、50、40、30、25、20、10、5、2、1、0.5、0.2、0.075mm |

|

Asphalt pavement aggregate screen (φ200, 300, 15 pcs/set + bottom cover) | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16.0、19.0、26.5、31.5、37.5、53mm |

|

Sand screen φ200×50 (8 pcs/set) | 10、5 |

| Square hole copper mesh 2.5, 1.25, 0.63, 0.315, 0.16, 0.08 | ||

|

Stone sieve φ300×70mm (12pcs/set) | 2.5、5、10、16、20、25、31.5、40、50、63、80、100mm |

|

Lime sieve (φ200 5pcs/set+bottom cover) | 0.125、0.71、0.9、5、20 |

|

Standard Pharmacopoeia Sieve φ200×50mm (9 pcs/set) | 2、0.85、0.355、0.25、0.18、0.15、0.125、0.09、0、075mm |

Stone test sieve: 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm, plus bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90mm, plus bottom cover

Sand est sieve: 0.08, 0.16, 0.315, 0.63, 1.25, 2.5, 5, 10mm, plus bottom cover or 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5mm, plus bottom cover

Soil test sieve: 0.074, 0.25, 0.5, 1, 2, 5, 10, 20, 40, 60mm plus bottom cover

Asphalt aggregate screen specifications: 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5, 13.2, 16, 19, 26.5, 31.5, 37.5, 53mm, plus bottom cover

Provide various sizes of standard sieve, soil sieve, sand sieve and other sieves, the sieve size can be customized.

1. Precise and durable mesh

A wide range from 150 mm to 0.005 mm (5 microns) can be inspected by technical supervision bureaus at all levels (the company promises to return unconditionally if the inspection fails).

2. SS304 stainless steel

The sieve frame is made of stainless steel SS304, which will never rust, non-magnetic, and precise, and will not leak materials and water. The wall thickness is 0.6MM, which is durable and not deformed.

3. Resistant to high temperature of 400 ℃

The screen mesh and the screen frame are connected by welding, which can withstand high temperature of 400 ° C and can be used for inorganic and organic solutions. The connection is firm, seamless, and does not clamp materials.

4. All sand test sieves are interchangeable

The shape can also be according to the shape and size of each country, with diameters of 400, 300, 203, 200, 127, 100, 75, etc. respectively. Meet the requirements of medicine, food, superhard materials (diamond, emery, etc.), chemical industry, feed, sand and gravel, minerals, metallurgy, metal powder and other industries.

1. Types of sieve surfaces

There are two types of commonly used screen surfaces: perforated plate screen surface and woven mesh screen surface. The punching screen surface is punched by 1mm~2.5mm thick low carbon thin steel plate, with high strength, the screen hole is not easy to deform, and it is easier to install on the equipment, the screen surface opening rate is low, and the screen hole size is 1mm ~125mm. The mesh shape of the woven mesh screen surface is square hole, which is cheap, widely used, light and durable, and the mesh size is 0.02mm~2.36mm.

2. Shape of the sieve hole

The sieve holes are generally round, oval, equilateral triangle and rectangle. The first three categories are mainly used for punching screen surfaces. The round holes on the screen surface are easy to process, have no stress concentration, have high strength, and are the most widely used, and their size is represented by diameter.

1. Accurately weigh 500g of the dried sample (extra-fine sand can be weighed as 250g), and place it on the top sieve (nominal diameter of 5.0 mm square hole sieve); put the sleeve sieve into the shaker and fasten it, sieve for 10 minutes, then take out the sleeve sieve, and then carry out hand sieving one by one on a clean shallow plate according to the order of sieve holes from large to small. , until the sieving amount per minute does not exceed 0.1% of the total sample, the passing particles are incorporated into the next sieve and hand sieved together with the samples in the next sieve. Follow this sequence until all the sieves have been sieved.

Note: 1 When the mud content of the sample exceeds 5%, the sample should be washed first, then dried to constant weight, and then sieved; if there is no shaker, the hand sieve can be used instead.

2. Weigh the quality of the remaining samples of each sieve (accurate to 1g), and the sum of the remaining sieves of all sieves and the remaining amount in the chassis shall not differ by more than the total amount of samples before sieving. 1%.

The results of the sieve analysis test shall be calculated according to the following steps:

1. Calculate the sieve remainder (the sieve remainder on each sieve divided by the percentage of the total sample), accurate to 0.1%.

2. Calculate the cumulative sieve residue (the sum of the sieve residue of the sieve and the sieve residue of each sieve whose sieve hole is larger than the sieve), accurate to 0.1%.

3. According to the average value of the accumulated sieve residues of the two tests of each sieve, the particle gradation distribution of the sample is evaluated, with an accurate value of 1%.

4. The fineness modulus of sand should be calculated according to the following formula, accurate to 0.01.

5. Take the calculated average of the two test results as the measured value, accurate to 0.1. When the difference between the fineness modulus obtained from the two tests is greater than 0.20, the sample should be taken again for the test.

| Sand Seperate | Diameter Range | Standard Sieve No. | % |

| millimeters | Retained | ||

| Gravel | 2.0 and larger | 10 | 17.80% |

| Very Coarse Sand | 2.0 - 1.0 | 18 | 2.00% |

| Coarse Sand | 1.0 - 0.5 | 35 | 4.60% |

| Medium Sand | 0.5 - 0.25 | 60 | 15.20% |

| Fine Sand | 0.25 - 0.10 | 140 | 16.30% |

| Very Fine Sand | 0.10 - 0.05 | 270 | 3.90% |

| Fines | less than 0.05 | -- | 40.10% |

Sand generally refers to fine stones, sand, gravel, glass sand, etc. Laboratory test sieves play a very important role in the particle size detection and particle size distribution of sand. The test sieve used in the laboratory has a standard detection mesh and is easy to operate. It can be installed with 1-6 layers of sieve frames, and can detect 6-7 specifications of different sizes at the same time. It is widely used in laboratories of universities, enterprises, and research institutes.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.