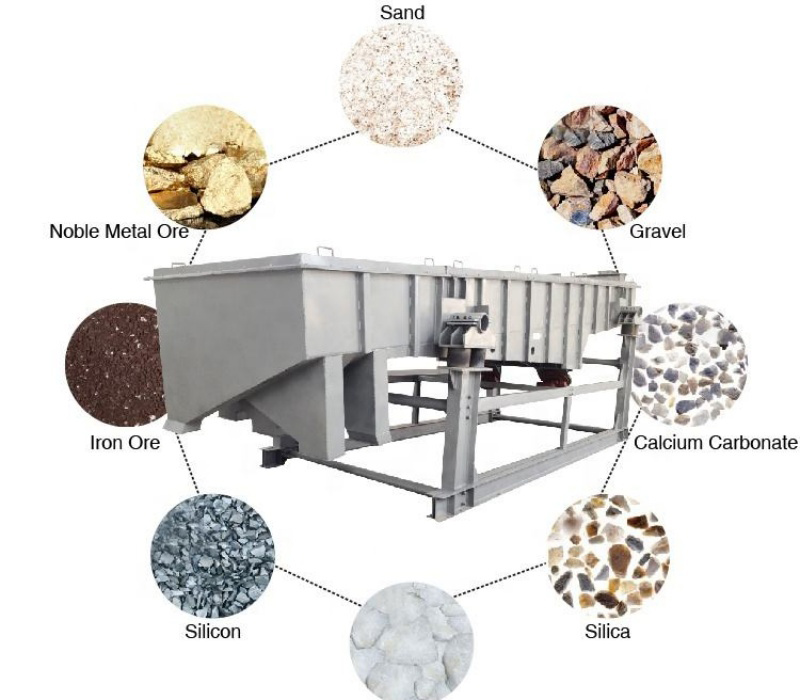

Used for screening and classifying granular materials such as sand, ore, construction waste, etc.

![]()

![]()

Price::$500.00 - $6,500.00/Set

Consult now and enjoy a 10% discount

Mesh number: 400 mesh

Feeding particle size: 0.074-10mm

Capacity: 0.12-20 tons/hour

Motor Power: 2*(0.4-3.7)kw

Application: Sand sifter machines are widely used in construction engineering, cement production, mining and other fields to screen granular materials such as sand, ore, and construction waste.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Sand sifter machine is a mechanical equipment used to screen and classify granular materials such as sand, gravel, ore. Through linear vibration screening, the particles in the raw materials are separated according to different particle sizes, impurities are removed, and the quality and purity of the materials are improved. In the production of sand and gravel, sand sifter machine is an indispensable screening equipment. After the machine-made sand is crushed, the coarse particles larger than 5mm must be removed first, and then the sand is divided into coarse, medium and fine sands of different particle sizes. The sub is used for ingredients.

In the process of designing the sand and gravel production line, the output of the industry is generally relatively large, and the ordinary single sifter machine cannot meet its high output requirements, and it can only be achieved with multiple sifter machines. When arranging the sand and gravel production line, it is very troublesome to distribute and connect multiple sieve machines. At this time, the advantages of the sand sifter machine dedicated to sand and gravel are highlighted. In large and medium-sized gravel production lines, it is generally necessary to configure 4-6 sets of screening equipment, and even a small gravel production line requires at least two sifter machines.

1. Screening of large particle sand and gravel

When sieving sand and gravel materials larger than 3mm, the production capacity is the service life of the equipment, and a large linear vibrating screen can be considered. It has the characteristics of simple structure, large capacity, simple operation, and long service life of the equipment. It is the current large-grain sand screen. Common screening equipment in stone screening.

2. Screening of 3mm-120 mesh sand and gravel

When screening 3mm-120 mesh sand and gravel, it is necessary to consider the screening accuracy, production capacity and dust spillage. The production capacity of sand and gravel within this specification is generally 30-50 tons per hour, the accuracy requirement is above 95%, and the environmental requirements are correspondingly high, so ordinary linear screens cannot be realized, and it is recommended to use a square tumbler screen.

Sand sifter machine can not only be used to classify and screen finished sand and gravel, but also can be used to screen materials crushed by primary crushing equipment and secondary crushing equipment, and return crushed materials or stone powder, impurities, etc. Screening is distinguished, and it can be connected with the host equipment through a belt conveyor to form a closed loop. In the sand and gravel production line, multi-layer sand sifter machines are generally used in parallel operation, so that the materials can be sieved at one time, saving a lot of production time and meeting the needs of the finished aggregate particle shape.

Application Industries of Sand Sifter Machine:

Sand sifter machines are widely used in construction, mining, metallurgy, chemical industry and other fields.

In the construction industry: Sand sifter machines are used to produce sand and gravel particles required for concrete to ensure concrete quality.

In the mining field: Sand sifter machines are used to screen ores, separate useful ores, and improve the grade of the ores.

In cement production: Sand sifter machines are used to screen and classify raw materials to ensure the smooth progress of the production process.

In construction waste treatment: Sand sifter machine can screen sand and gravel and other particles in construction waste.

When the sand sifter machine is started, two vibrating motors or exciters of the same type and specification symmetrically arranged run synchronously and reversely, and the exciting force generated by them is transmitted to the entire vibrator through the vibration transmission body—the base of the motor or exciter. The vibrating body—on the screen box, makes the screen box drive the screen surface to vibrate periodically, so that the materials on the screen surface make a directional jumping movement together with the screen box, during which, the materials smaller than the aperture of the screen surface fall to the lower layer through the screen holes, It becomes the undersieve, and the material larger than the aperture of the sieve surface is discharged from the discharge port after continuous jumping motion, and the screening operation is completed.

Precise classification

It can simply screen the fine powder and oversized particles in the sand and gravel, and can also divide the sand into 7 different specifications according to the particle size ratio requirements.

Efficient screening

High throughput, up to 20 tons of sand and gravel can be removed per hour, and the efficiency is over 96%.

Easy to maintain

It can withstand material fluctuations and requires minimal maintenance. It only takes a few minutes to replace the screen.

Versatility

The upper cover of the equipment is designed with a dust removal device. It can be easily connected with on-site dust removal equipment. In a large-scale production line, multiple screening equipment can be configured.

Energy saving

Using advanced design and technology, sand sifter machine can save energy and reduce production costs during the screening process.

Reduce environmental pollution

Sand sifter machine can effectively control the generation of dust during the screening process, reduce environmental pollution, and meet environmental protection requirements.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.