The sieving fineness can reach 500 mesh (28 microns), and the filtration fineness can reach 5 microns. It is not easy to be clogged and has high sieving efficiency.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Motor power: 0.25Kw to 2.2Kw or customized

Application field: impurity removal and classification of various dust, granule and slurry materials

Application:

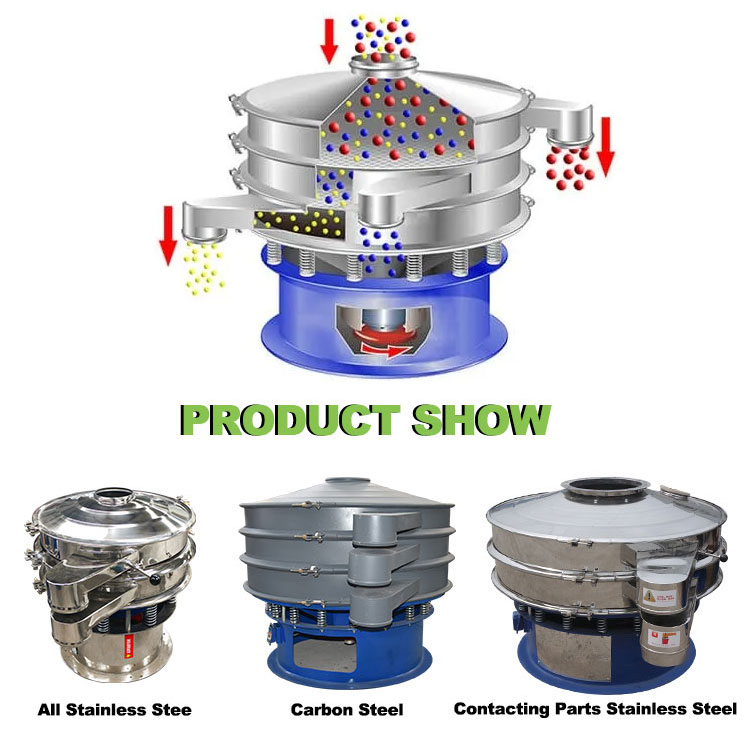

Shaker sifter can meet various powder and particle screening needs and liquid filtration needs. It can be used in a wide range of 0-500 mesh dry, wet, fine, rough, large and small specific gravity powders and particles, and 0-600 mesh slurry materials can be easily screened. Filter easily. We tailor the most suitable rotary vibrating screen equipment for each user according to the needs of different users' material characteristics, processing capacity, screening goals, site restrictions, production line configuration and other characteristics.

1. Use vertical vibration motor. There is no loss in the transmission process of the exciting force, because there is no mechanical transmission, it is effectively transmitted to the screen surface.

2. Made of high-quality stainless steel. The unique grid design solves the problem of screen clogging and sinking.

3. The airtightness is good, the powder does not splash, and the liquid does not penetrate.

4. 0-500 mesh screen, other sizes are customized and sold separately. If necessary, please feel free to contact us.

5. It can be used in single or multiple layers, and can screen 2-6 different specifications at the same time.

Shaker Sifter uses a vertical vibrating motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the motor's rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the sieve Screen the noodles. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 |

| DH-600 | 600 | 0.25 | |||

| DH-800 | 800 | 0.55 | |||

| DH-1000 | 1000 | 0.75 | |||

| DH-1200 | 1200 | 1.1 | |||

| DH-1500 | 1500 | 1.5 | |||

| DH-1800 | 1800 | 2.2 |

Ordinary type: use the simple adjustment of the counterweight on the motor shaft and the three-dimensional vibration they generate to screen materials, which can be used to remove broken or undersized products, and can provide up to 5 levels of classification in one operation to achieve precision particle size distribution

Ultrasonic type: use ultrasonic system to apply high-frequency vibration to the screen, the frequency of vibration breaks the surface tension, makes the stainless steel mesh effectively friction-free, and prevents oversized and undersized particles from clogging or clogging the mesh screen, which can be used in finer mesh Sieve on a fine grid (down to 20 microns).

In-line type: the inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom enables the material to be discharged directly. The discharge speed is fast, and the output is 2-5 times that of ordinary round sieves. foreign matter and impurities.

High-frequency type: A 2-stage motor is used as the excitation source to make the vibration intensity 2-3 times that of the ordinary vibrating screen, which can quickly destroy the surface tension of the viscous slurry entering the screen, thereby reducing their stay on the screen Time for fast filtering.

1. Removal of impurities: high fluidity powder processing, fast removal of large particles or fine powder with low content.

2. Grading and screening: Continuously select mixed materials of different particle sizes and classify them into different particle size grades. Can be divided into one, two, three, four and so on. What's more, only one operation can continuously filter up to 5 stages of product separation.

3. Solid-liquid separation: quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.