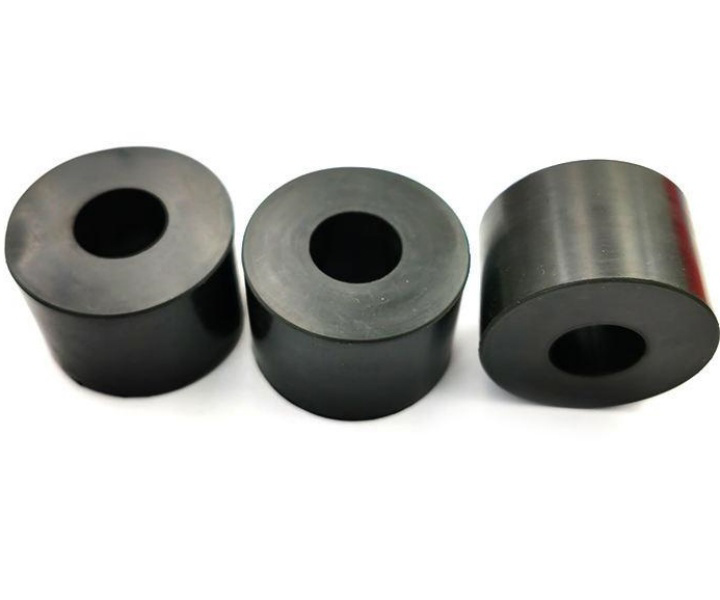

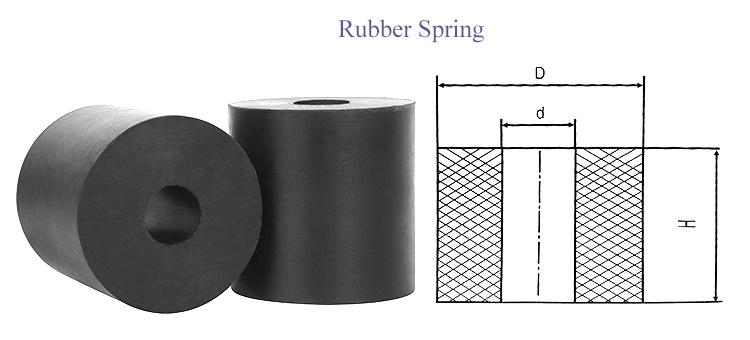

Elastic element made of rubber material for absorbing and damping vibrations

![]()

![]()

![]()

Price:$0.60/piece-$3.00/piece

Consult now and enjoy a 10% discount

Material: Rubber

Working load:80-2800Pa

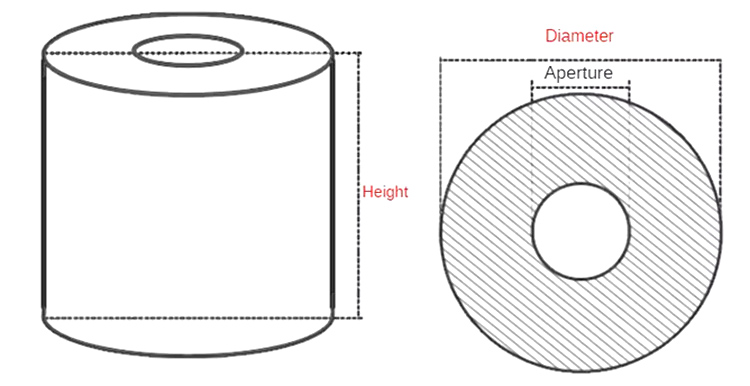

Outer diameter: 50-300mm

Inside diameter: 18-80mm

Free height: 50-245mm

Features: Higher internal resistance, can bear multi-directional loads at the same time, stiffness can be freely selected according to design requirements

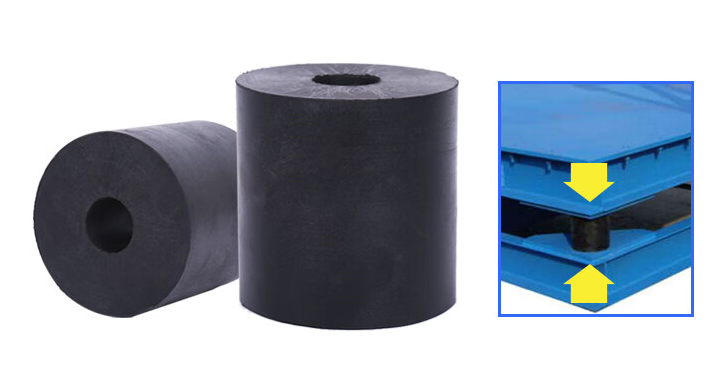

Use: Used in various vibration machinery to reduce vibration and buffer

Commitment:

Rubber spring is mainly made of rubber material, which has good elasticity and wear resistance, abrasion resistance and cold resistance. It can effectively absorb and dissipate energy, thereby reducing vibration and noise.

In industrial machinery and equipment, rubber springs are used to isolate and dampen vibrations caused by rotating or reciprocating machinery. They are often employed in applications such as vibrating screens, conveyors, crushers, and other equipment where vibration control is crucial. Rubber springs effectively reduce the transmission of vibrations, protecting the machinery and surrounding structures from excessive wear and damage.

The material of the vibrating screen rubber spring is crucial to the performance and service life of the vibrating screen equipment.

Natural rubber: has good elasticity and wear resistance, wear resistance, good cold resistance, but poor tolerance to oil, solvents and oxygen.

Synthetic rubber (such as nitrile rubber, propylene rubber, etc.): has good anti-aging, oil resistance, wear resistance and weather resistance, but the elasticity and heat resistance may be slightly inferior to natural rubber.

The primary function of a rubber spring is to absorb shock and vibration. This makes them ideal for a variety of applications where reducing the impact of external forces is crucial.

Here are some specific functions of rubber springs:

1.Vibration Isolation: Rubber springs can effectively isolate vibrations from machinery, equipment, and vehicles, reducing noise and protecting delicate components.

2.Shock Absorption: They can absorb shocks and impacts, preventing damage to equipment and structures.

3.Load Bearing: Rubber springs can support loads and distribute them evenly, reducing stress on components.

4.Noise Reduction: By absorbing vibrations, rubber springs can significantly reduce noise levels.

Rubber spring is an important vibration reduction element, which is widely used in various vibration machinery. Its main function is to absorb vibration energy, reduce noise, protect equipment and extend the service life of equipment.

Vibrating screen: This is the most common application field of rubber spring. Whether it is a linear vibrating screen, a circular vibrating screen or a mining vibrating screen, rubber springs can effectively absorb the vibration generated by the screen during operation to ensure the screening effect.

Vibrating feeder: Rubber springs can make the vibrating feeder produce stable vibration to ensure uniform conveying of materials.

Vibrating mill: In the vibrating mill, rubber springs can absorb the vibration generated by the mill and protect the equipment.

Vibrating conveyor: Rubber springs can provide stable vibration to ensure the conveying of materials.

Vibrating table: Rubber springs can provide stable vibration to improve the surface treatment effect of workpieces.

Working principle of rubber springs is based on the elastic properties of rubber materials. When external force is applied to a rubber spring, the rubber material will deform elastically. The molecular chains of the rubber will stretch and twist under the force, and when the external force is removed, the rubber spring will return to its original shape. The elastic properties of rubber springs enable them to absorb and damp vibrations. When external force acts on a rubber spring, the rubber material deforms elastically and stores energy. Once the external force is removed, the rubber spring releases the stored energy and generates a reaction force, thereby reducing or eliminating the effects of vibration.

Advantages:

The shape is not restricted, and the stiffness in each direction can be freely selected according to the design requirements.

Although the elastic modulus is small, a large elastic deformation can be obtained, and it is easy to achieve ideal nonlinear characteristics.

It has a high internal resistance. This has a good effect on the absorption of sudden impact and high-frequency vibration and sound insulation.

The same rubber spring can bear multi-directional loads at the same time, thereby simplifying the structure of the system.

It is easy to install and disassemble, and no lubrication is required, which is conducive to maintenance.

Disadvantages:

High and low temperature resistance and oil resistance are worse than steel springs.

Rubber springs used in engineering are simpler in shape than bellows, but it is quite difficult to calculate their elastic properties.

Because they are not pure elastomers, but viscoelastic materials, their mechanical properties are relatively complex.

| Specification D×H×d﹝mm﹞ |

Outer diameter D (mm) |

Inside diameterd (mm) |

Height H (mm) |

Work deformation FV (cm) |

Stiffness KL (kg/cm) |

Working load(Pa) |

| Ф50×50×Ф18 | 50 | 18 | 50 | 0.8 | 50 | 80 |

| Ф60×60×Ф20 | 60 | 20 | 60 | 0.8 | 60 | 100 |

| Ф80×80×Ф25 | 80 | 25 | 80 | 0.8 | 100 | 200 |

| Ф80×80×Ф30 | 80 | 30 | 80 | 0.8 | 100 | 200 |

| Ф100×100×Ф25 | 100 | 25 | 100 | 1 | 140 | 500 |

| Ф100×100×Ф30 | 100 | 30 | 100 | 1 | 140 | 500 |

| Ф100×130×Ф30 | 100 | 30 | 130 | 1 | 150 | 550 |

| Ф120×120×Ф30 | 120 | 30 | 120 | 1.2 | 220 | 600 |

| Ф120×140×Ф30 | 120 | 30 | 140 | 1.2 | 230 | 650 |

| Ф127×127×Ф30 | 127 | 30 | 127 | 1.2 | 230 | 640 |

| Ф130×130×Ф30 | 130 | 30 | 130 | 1.3 | 240 | 680 |

| Ф140×140×Ф30 | 140 | 30 | 140 | 1.4 | 300 | 700 |

| Ф140×160×Ф30 | 140 | 30 | 160 | 1.4 | 350 | 680 |

| Ф140×160×Ф40 | 160 | 40 | 160 | 1.4 | 350 | 680 |

| Ф160×160×Ф30 | 160 | 30 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф40 | 160 | 40 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф50 | 160 | 50 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф60 | 160 | 60 | 160 | 1.6 | 350 | 750 |

| Ф160×235×Ф40 | 160 | 40 | 235 | 1.6 | 400 | 800 |

| Ф160×240×Ф40 | 160 | 40 | 240 | 1.6 | 400 | 800 |

| Ф180×180×Ф40 | 180 | 40 | 180 | 1.8 | 400 | 800 |

| Ф180×240×Ф40 | 180 | 40 | 240 | 1.8 | 400 | 1000 |

| Ф200×150 | 200 | 150 | 1.5 | 380 | 900 | |

| Ф200×150×Ф65 | 200 | 65 | 150 | 1.5 | 350 | 800 |

| Ф200×200×Ф40 | 200 | 40 | 200 | 2 | 450 | 1000 |

| Ф200×200×Ф50 | 200 | 50 | 200 | 2 | 450 | 1000 |

| Ф200×300×Ф50 | 200 | 50 | 300 | 2 | 480 | 1300 |

| Ф220×220×Ф40 | 220 | 40 | 220 | 2.2 | 500 | 1500 |

| Ф220×220×Ф50 | 220 | 50 | 220 | 2.2 | 500 | 1500 |

| Ф240×240×Ф50 | 240 | 50 | 240 | 2.4 | 550 | 1800 |

| Ф250×250×Ф50 | 250 | 50 | 250 | 2.5 | 580 | 2000 |

| Ф300×245×Ф80 | 300 | 80 | 245 | 1 | 480 | 2800 |

Rubber springs and steel springs are two common types of springs, which have some differences in materials, elastic properties and application areas.

Material: Rubber springs are made of rubber materials, while steel springs are made of metal steel.

Elastic properties: Rubber springs have good buffering and rebound properties, can absorb and damp vibrations, and have a certain degree of softness. Steel springs have high elasticity and strength and can withstand large forces and deformations.

Load capacity: Due to the high strength and rigidity of steel springs, they are usually used in applications that need to withstand large loads and deformations, such as automotive suspension systems, industrial machinery, etc. Rubber springs are suitable for light loads and vibration damping occasions, such as building structures, electronic equipment, etc.

Damping effect: Rubber springs have good damping characteristics and can effectively reduce vibration transmission and noise generation. The damping effect of steel springs is relatively low.

There are several key factors to consider when choosing rubber springs:

Load requirements: First you need to determine the required load range. Rubber springs should have sufficient load carrying capacity to support the required operating load. Load requirements can be determined based on factors such as the size of the vibrating screen, material properties and working conditions.

Vibration characteristics: The vibration characteristics of the vibrating screen are crucial to the selection of rubber springs. The amplitude, frequency and working mode of the vibrating screen need to be considered. Different vibration characteristics may require rubber springs of different hardness, shape and number to achieve the desired vibration control effect.

Environmental conditions: The working environment is also important for the selection of rubber springs. Temperature, humidity, the presence of chemicals, and possible corrosion and wear factors need to be considered. Choose rubber materials with wear resistance, corrosion resistance and high temperature resistance to ensure the long-term stability of the rubber spring in harsh environments.

Spring design: The design of the rubber spring should match the structure and installation method of the vibrating screen. The shape, size and placement of the rubber spring need to be considered to ensure it will fit correctly and provide the required shock absorption and isolation.

Quality and Reliability: It is very important to choose rubber springs with good quality and reliability. High-quality rubber materials and manufacturing processes can ensure that rubber springs have stable performance and long service life.

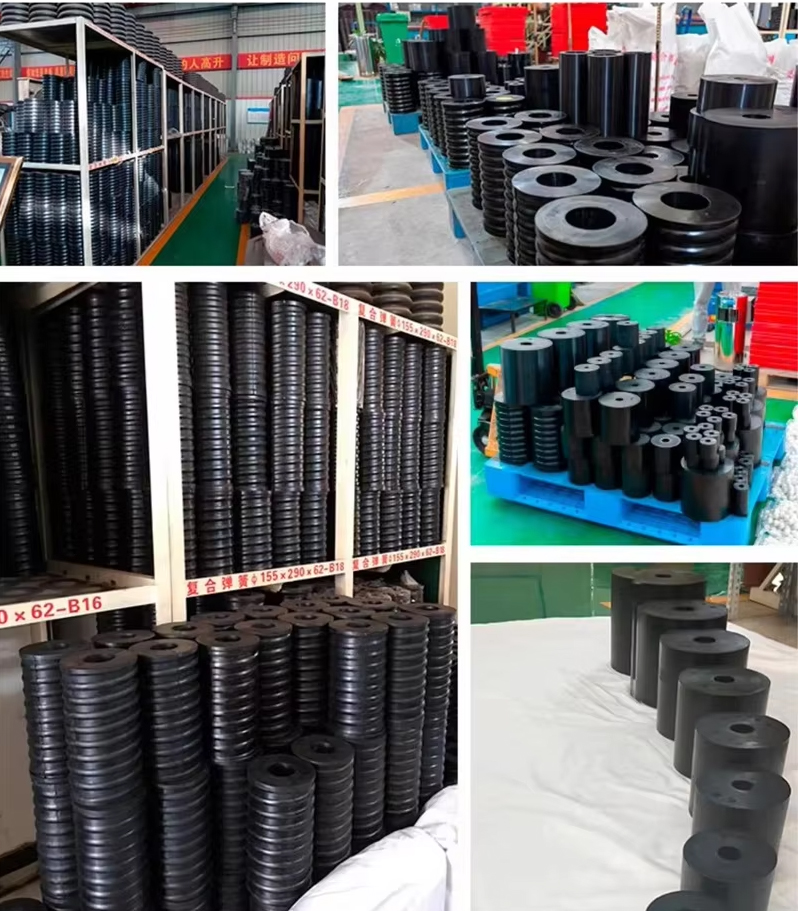

Dahan Factory is committed to designing, manufacturing and selling high-quality rubber springs to meet the shock absorption and vibration control needs of various industries. Dahan pays attention to product quality and performance, using high-quality rubber materials and advanced production processes to ensure that its rubber springs have good elasticity, durability and anti-aging properties. Dahan's rubber springs are widely used in mechanical equipment, automobiles, construction projects, power equipment and other fields. They can effectively absorb and damp vibrations and protect the safe and stable operation of equipment and structures. The products produced have the advantages of reliable performance and strong customizability, which can meet the special needs of customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.