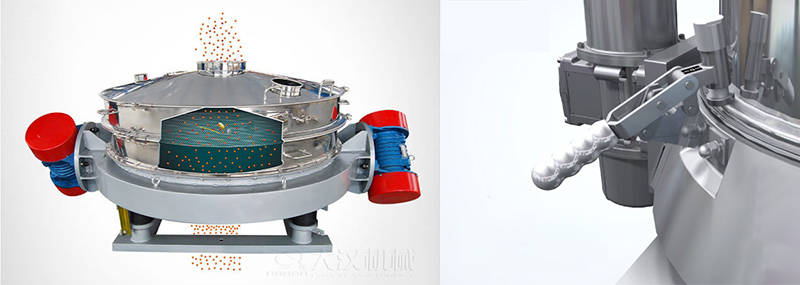

Quick release clamp for vibratory screener for quick and easy disassembly and cleaning, provides consistent and even clamping pressure, simple quick release design, easy to operate, set up and inspect.

This quick release clamp for vibratory screener can be used to screen, classify, separate, screen or exfoliate bulk materials and is widely used in almost all process industries including pharmaceutical, chemical, plastics and food. Capable of separating up to five parts of material, this rotary vibratory separator can be installed in any size production plant, from small units to high volume production plants, to meet the requirements of a variety of applications.

Quick release clamp can be easily retrofitted to any vibratory screener to provide an even dust seal, and the super clamp system is easily removable and can be easily retrofitted to any vibratory screener.

This range of screening machines, also known as safety screening machines, is used to ensure quality by inspecting and removing foreign contaminants and oversized materials from products.

The Quick release clamp for vibratory screener has two vertically installed motors on each side. The material enters the ibratory screener through the feed port. According to different material screening requirements, the material passes through the screen layers of different mesh screens, and the material larger than the screen aperture Left on the screen surface, it is discharged from the upper discharge port, and the material smaller than the screen aperture is quickly passed through the screen and discharged from the lower discharge port.

1. Simple quick release design, easy to operate, set and check.

2. The material inlet and outlet are vertically designed, and the large flow outlet at the bottom enables the material to be discharged directly, the material discharge speed is fast, and the output is 2-5 times that of the ordinary round screen.

3. Extend the life of machine clamp pads and washers and minimize clamp replacement.

4. It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution to materials.

5. The screening device is completely sealed to prevent contamination.

Sieving laundry detergent

quick release clamp for vibratory screener

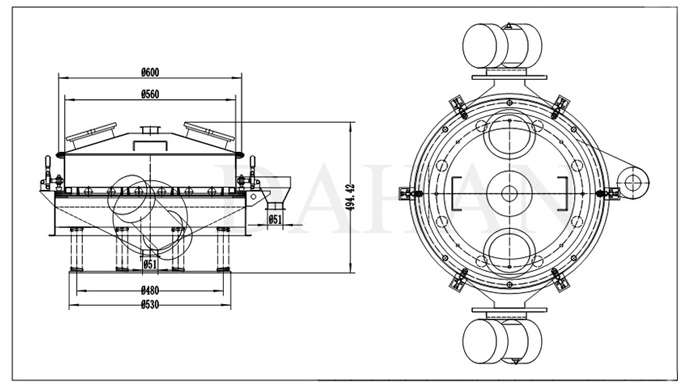

| Model | Power(kw) | RMP(r/min) | Sieve diameter(mm) | A | B | C |

| ZPS-600 | 0.18 | 1460(960) | 520 | 1070 | 600 | 502 |

| ZPS-800 | 0.25 | 720 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 890 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1090 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 1390 | 2226 | 1470 | 875 |

Quick release clamp for vibratory screener can be used to remove any oversized contaminants in the raw material and then remove the undersized particles after pelletizing, with continuous filtration for up to 5 stages of product separation in just 1 operation.It can screen and filter powders and granules within 400 meshes, and is widely used in washing powder, chemical fertilizer, medicinal powder, salt, monosodium glutamate, seasoning, milk powder, starch, flour, rice flour, carbon powder, graphite powder, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.