Portable auger conveyor

Portable auger conveyor Portable flexible auger conveyor

Portable flexible auger conveyor Portable screw conveyor

Portable screw conveyor Stainless steel portable Auger Conveyor

Stainless steel portable Auger Conveyor Portable vertical auger conveyor

Portable vertical auger conveyor

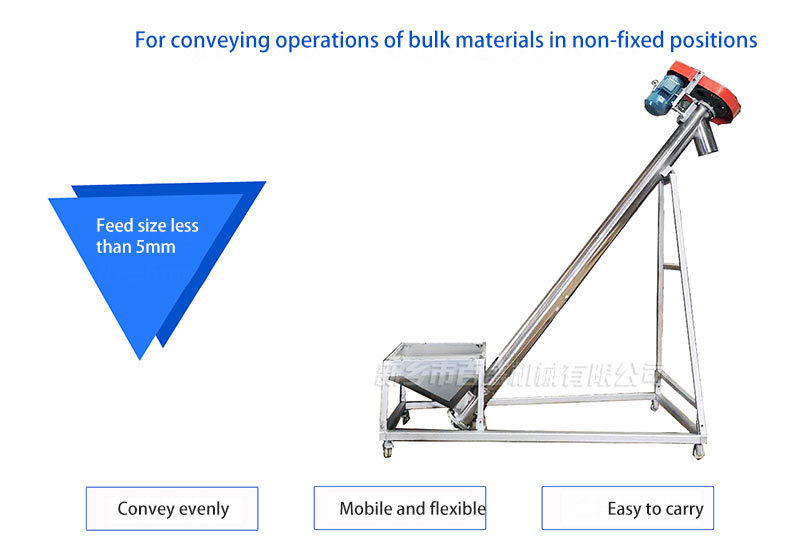

Easy to move, suitable for bulk material loading and other unfixed position transportation

![]()

![]()

Price:$800.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Screw diameter: 102-325mm

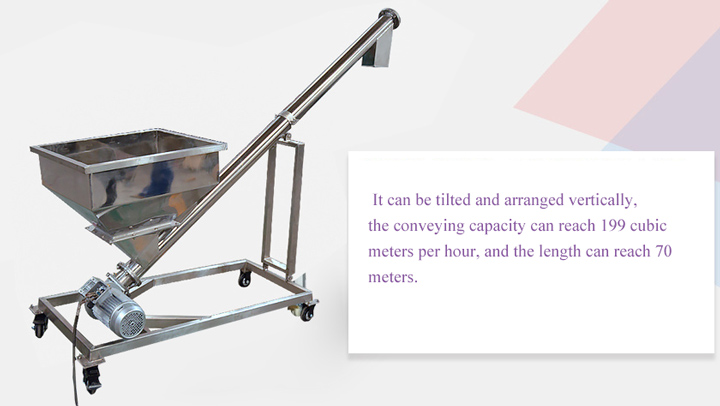

Conveying capacity: 1.2-199m³/h

Conveying length: 2-70 meters

Delivery angle: 30-90 degrees

Screw speed: 25-140 rpm

Frame material: SUS304/carbon steel

Application: It can be moved freely according to the material stacking position, used for conveying bulk materials in feed, chemical, food processing, and grain processing, grain storage, various additives, construction engineering and other industries.

Promise:

Portable auger conveyor is a conveying system usually consisting of a tube or trough containing a rotating auger or screw that moves material along the length of the conveyor, which is mounted on wheels or a trailer and can be easily Ground transport between different locations, designed to move easily from one location to another, it is commonly used in agricultural applications for transporting grain, seeds and other small materials.

Portable auger conveyors can be designed to run in different orientations, including horizontal, inclined or vertical, depending on specific application requirements. They can also be customized with features and functions such as adjustable discharge heights, telescoping conveyors and hydraulic controls.

Portable auger conveyor can be divided into different materials and conveying angles according to conveying materials and site conditions:

1. Carbon steel material: Q235 carbon steel material, suitable for conveying common materials.

2. Stainless steel material: It is made of 304 or 316 stainless steel, which is resistant to acid and alkali corrosion, high temperature resistance of 200 ° C, clean and hygienic, anti-rust, suitable for some industries with relatively strict sanitary conditions.

3. Inclined type: use the motor to drive the spiral rotation through the reducer, and through the rotation, the material is moved along the fixed casing to carry out the conveying work, so as to convey the material to the predetermined position, the inclination angle is 0-60°, and the conveying length generally does not exceed 6 meters (can also be customized according to user site conditions)

4. Vertical type: use the centrifugal force generated by the high-speed spiral body in the vertical circular shell to overcome the friction force between the material and the surface of the spiral with the help of the friction force between the material and the outer shell, and the component force that slides down the spiral caused by the weight of the material , lift the material upwards. The lifting height is generally not higher than 5 meters.

Portable auger conveyors provide a versatile, customizable and cost-effective solution for small material transportation in a variety of industries and applications. They are designed to move easily from one location to another, providing flexibility and mobility to meet specific application requirements. Here are some common uses and benefits of portable auger conveyors:

1. Agriculture: In agriculture, it is usually used to transport grain, seeds and other small materials between storage bins, trucks and other handling equipment. They offer flexibility, mobility and customization options to meet specific application needs.

2. Construction: Used to transport small materials such as sand and gravel between different locations on a job site. They offer ease of use and mobility for efficient material transport.

3. Waste Management: Used to transport small materials such as sawdust and wood chips between different areas of the facility. They offer flexibility and customization options to meet specific application requirements.

4. Mining industry: used to transport minerals, ores and other small materials between different processing or storage areas. They provide ease of use and mobility in remote or hard-to-reach locations.

5. Food processing: used in the food processing industry to transport grains, seeds and other small materials, such as nuts and seeds, for processing and packaging. They offer custom options to meet specific hygiene and regulatory requirements.

Conveying grain

Conveying flour

Portability

There is a portable base installed under the equipment, which can be moved at will, especially suitable for the operation of unfixed position such as bulk material loading.

Adjustable tilt angle

Inclined or vertical conveying, conventional 45 degrees, can be customized at any angle within 30~90 degrees, the inlet and outlet and the inclination angle can be designed and installed according to the site conditions.

Delivery volume

The conveying capacity can reach 142 cubic meters per hour, the length can reach 30 meters when conveying incline, and the height can reach 5 meters when vertically lifting.

No dust pollution

The shell is made of steel pipes to connect all parts as a whole through flanges, which has good sealing and reduces dust.

Quick disassembly

The screw motor and the vibration motor are independently controlled, and the material box is designed as a separate type. The material box vibrates and the amplitude is adjustable, which is easy to load and unload.

Less maintenance

The screw can be reversed for discharging, the lower end of the material tube has a gate for discharging, and the whole screw can be easily taken out, which is convenient for inspection and maintenance.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The rotating helical blade pushes the material to be conveyed by the portable auger conveyor. What prevents the material from rotating with the screw conveyor blade is the material's own weight and the frictional resistance of the screw conveyor casing to the material. With the transmission of the screw blade, the material is driven to move to the discharge port.

The main components are: driving device, bearing housing, screw shaft, screw blade, feed port, feed port, machine trough, etc.

Can be customized according to your requirements, such as flange diameter, distance between inlet and outlet, installation inclination, shape (U-shaped, tubular, shaftless), inlet size, etc., and can also be combined with screens, mixers, silos, etc.

Portable auger conveyors can be used in combination with various other equipment to create a complete material handling system. Here are some examples of matching equipment that can be used with a portable screw conveyor:

1. Hoppers and Silos: Hoppers and silos can be used to hold materials before feeding them into the portable auger conveyor. These storage containers can be designed to accommodate different volumes and material types, depending on the specific application requirements.

2. Bucket Elevators: Bucket elevators can be used to lift materials vertically and feed them into the portable auger conveyor. This can be useful in applications where the material needs to be transported to a higher elevation.

3. Vibratory Feeders: Vibratory feeders can be used to regulate the flow of materials into the portable screw conveyor. These feeders use vibration to move material at a controlled rate, ensuring consistent material flow into the conveyor.

4. Bag Dump Stations: Bag dump stations can be used to unload bags of material into the portable screw conveyor. These stations can be designed with various features, such as dust collection systems and bag compaction mechanisms.

5. Dust Collection Systems: Dust collection systems can be used in conjunction with the portable auger conveyor to collect and remove dust and other airborne particles generated during material handling.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.