It is the transportation of plastering mortar from one location to another within a construction site or industrial facility.

![]()

![]()

Price::$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt Width: 500-1800mm

Height of Sidewall: 80-500mm

Belt Speed: 0.8-4.0m/s

Angle of Inclination: 30-90 degrees

Capacity: 84-5036m³/h

Application: For efficient delivery of plastering mortars in construction and plastering applications.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

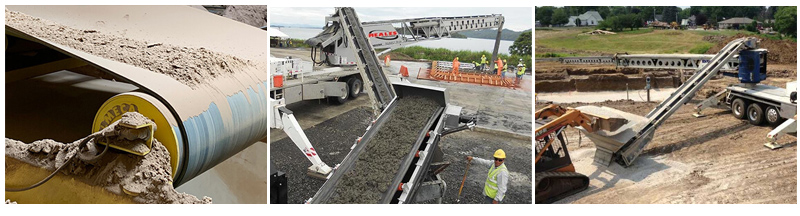

Plastering mortar belt conveyor is a type of conveyor system specifically designed for transporting plastering mortar or other similar materials in a construction or plastering application. It is commonly used to efficiently move the mortar from a mixing station to the desired location for plastering or rendering.

The use of belt conveyors to transport plastering mortar eliminates the need for manual handling, reducing labor costs and thereby improving efficiency. Conveyor systems help maintain consistency in plaster mortar application by ensuring a continuous and even flow of material. By automating the transport process, belt conveyors reduce manual handling risks and help create a safer working environment.

Rendering mortar belt conveyors are used in a variety of applications related to the transport and distribution of rendering mortar in construction projects. Some common applications include:

1. Plastering operation: It is used to transport the plastering mortar from the mixing station or storage area to the construction site. The conveyor ensures a continuous supply of mortar, increasing efficiency and reducing manual labor.

2. Building construction: used for building construction projects that require plastering. They help to transport the mortar to different areas of the building, such as walls, ceilings or surfaces that need to be plastered.

3. High-rise buildings: In high-rise buildings or structures, plastering needs to be done at different heights, and belt conveyors can be used to transport mortar to different heights. Conveyor systems can be designed to accommodate the vertical movement of the plastering material, simplifying logistics and reducing the need for manual handling.

4. Plastering machine integration: The plastering mortar belt conveyor can be integrated with the plastering machine or spraying equipment. The conveyor delivers the mortar to the machine, which then applies it to the desired surface. This integration increases the overall efficiency of the plastering process and ensures a constant supply of mortar to the machine.

Efficiency

It streamlines the process of transporting plastering mortar, saving time and labor compared to manual handling or using alternative methods.

Accuracy and Consistency

The conveyor system ensures a consistent flow and delivery of plastering mortar, helping to maintain a uniform application and avoid inconsistencies in plaster thickness.

Increased Productivity

By automating the material transport, the conveyor system allows workers to focus on the plastering task, increasing overall productivity and reducing fatigue.

Versatility

The conveyor system can be customized in terms of length, width, and height to suit different construction sites and plastering requirements. It can be used in various plastering applications, including walls, ceilings, and other surfaces.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

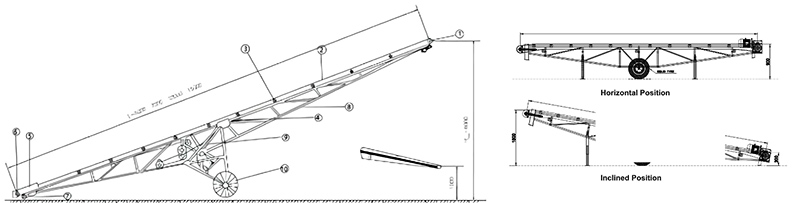

Plastering mortar belt conveyors usually consist of the following components:

Conveyor belt: The main component used to transport materials such as plastering mortar, usually made of wear-resistant materials.

Height adjuster: used to adjust the height of the conveyor belt to adapt to different working scenarios and requirements.

Copper motor: As a key part of the transmission device, it provides power to drive the conveyor belt to operate.

Omni-directional wheel: supports the conveyor belt, maintains its stable operation, and adjusts the tension and direction of the conveyor belt.

Sidewall: used to limit side leakage of materials during transportation to ensure the stability of transportation.

Hopper: used to load and transport materials to ensure continuous transportation of materials.

Galvanized square steel: constitutes the main structure of the conveyor and has strong load-bearing capacity and stability.

Capacity: Select a plastering mortar belt conveyor with the appropriate capacity to meet the specific material transportation requirements of the application.

Compatibility: Ensure that the conveyor system is compatible with the type of plastering mortar being used to prevent clogging or other operational issues.

For Construction Company

A construction company in Malaysia was working on a large residential project that required a large amount of plastering mortar for both wall and ceiling plastering work. They chose belt conveyors to transport the plastering mortar from the mixing plant to the construction site.

For Building Materials Supplier

An Italian building materials supplier specializes in providing plastering mortar and other building materials for various construction projects. To better meet customer needs, they invested in a belt conveyor system. This allows them to more quickly and efficiently transport large quantities of plaster mortar from the production line to the storage facility and supply it to customers in a timely manner.

For Engineering Contractors

An engineering contractor in Singapore was responsible for interior renovation work on a commercial construction project, which included plastering of walls. In order to improve construction efficiency, they used belt conveyors to transport plastering mortar to the construction area. This reduces workers’ time and effort on handling and transportation, allowing them to focus more on the quality and detail of the plastering job.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.