Introduction of Pharmaceutical Powders Sieving Machine

Traditional Chinese medicine powder is generally made of Chinese medicinal materials such as Panax notoginseng, ginseng, salvia miltiorrhiza, ganoderma lucidum, licorice, Liushen, rhubarb, bletilla striata, Xiyang ginseng, sealwort, spirulina, pearls, etc., which are ground or air-pulverized into single powder or compound powder (mixed ) after sieving by pharmaceutical powders sieving machine, the main purpose is to remove impurities and remove large particles.

Removal of impurities and large particles; during the sieving process, the dust of traditional Chinese medicine powder is serious, which not only causes the precious traditional Chinese medicine powder to be lost in vain, but also the on-site operators have to be attacked by the powder for a long time, which makes the workers miserable.

Crushing-drying-drying-sieving-packaging

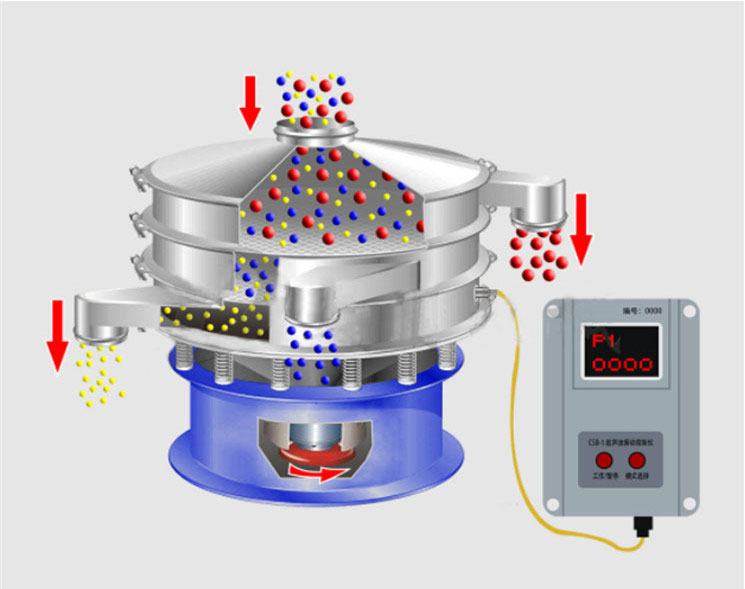

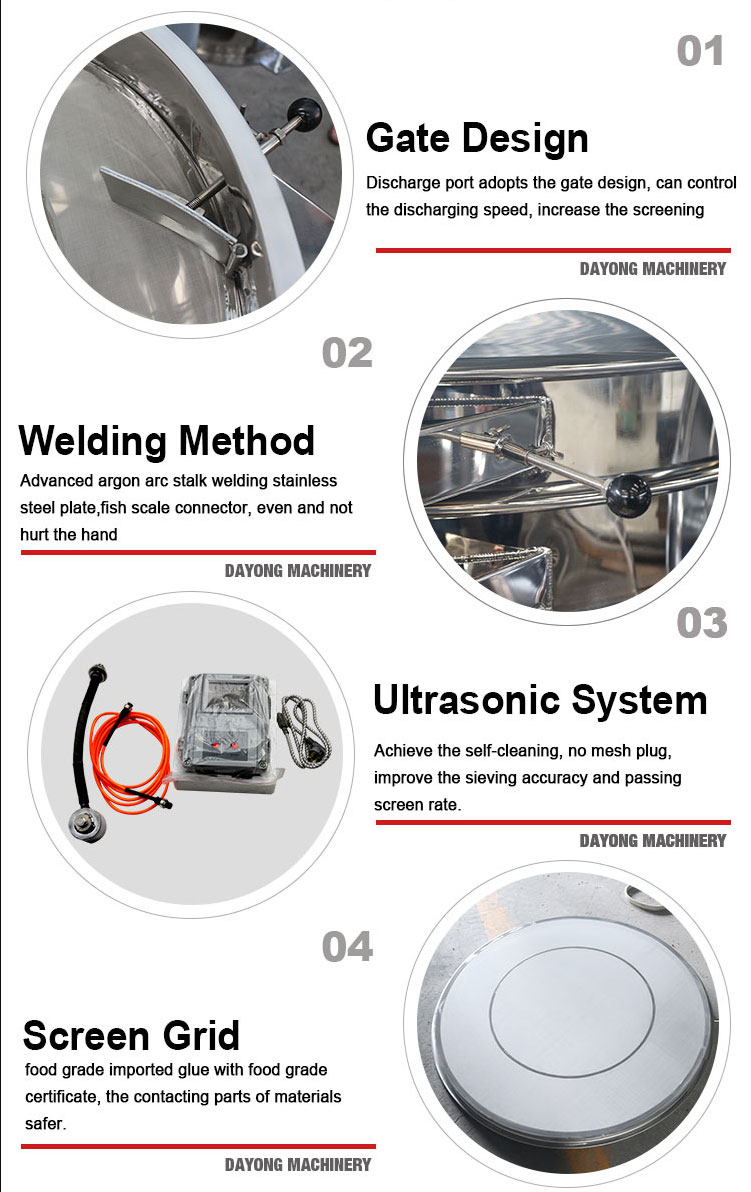

The ground pharmaceutical powder has a lot of fiber content and is difficult to sieve. The specific gravity is light. During the sieving process, the sieving equipment can not meet the screening needs of the site due to the fact that the material is easy to clump during the sieving process and block the screen. Our sieving machine equipped with an ultrasonic anti-clogging system uses revolutionary innovative technology to sieve fine powder, and the pore size can reach 20 microns. The industrial ultrasonic sieving machine can also increase screening capacity and reduce screen damage.

1. The addition of an ultrasonic anti-blocking device improves the quality of powdered medicines, increases production capacity and ensures accurate particle size separation. Reduce the mesh size to 20 microns (635 mesh).

2. Provide up to five powders in one operation, ensuring the highest quality sieved products to meet requirements, an innovative solution for peace of mind for customers.

3. It also reduces production downtime by preventing screen clogging and breakage, and reduces man-hours required to clean screens.

4. It is made of SUS304 or 316L stainless steel. The inside and outside of the sieve machine are polished, clean and hygienic, without dead ends, easy to clean and disinfect, and meet the hygienic standards of the pharmaceutical industry.

5. Automatically process the screened pharmaceutical impurities and particles. After screening, it can automatically enter the next round of screening work, saving labor and continuous operation.

Pharmaceutical powders sieving machine is mainly used in the pharmaceutical industry to remove impurities in various types of pharmaceutical powders. The sieving machine sieves layer by layer through sieves with different meshes. The coarse material remains on the sieve, and the fine material is sieved smoothly to achieve effective Screening action. It can be used to screen out fine powder or impurities, such as screening of Chinese medicinal materials, removal of debris and impurities, and powder classification to meet the requirements of pills, powders and other preparations.

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.