The mesh is not blocked, the powder is not flying, and can be sieved to 400 mesh or 0.028mm

![]()

![]()

![]()

Price:$800.00-$5,000.00 /Set

Consult now and enjoy a 10% discount

Mesh size: 4-200mm

Processing capacity: 12-600t/h

Layers: 1-5 layers

Tilt angle: 15-30 degrees

Power: 7.5-37KW

Application scope: Resins, coatings, industrial chemicals, cosmetics, paints, traditional Chinese medicine powder, etc.

Commitment:

Mobile vibrating screen is equipped with a movable universal wheel at the bottom of the mobile vibrating screen, with a feed bin, which can fill the bin at one time, and then adjust the butterfly valve on the bin to control the flow of the material into the bin's rotary vibrating screen for screening. The characteristics of this product are intermittent feeding, without the need for workers to continuously feed and save labor. The butterfly valve can control the flow rate to improve the screening accuracy. At the same time, the silo can be rotated and vibrated for mobile operations to meet the work needs of different locations.

Mobile vibrating screen with silo

Plastic particle mobile vibrating screen

1. A universal wheel is installed at the bottom, which can rotate 360 degrees and can be operated by one person.

2. High efficiency, exquisite design and durable, both powder and mucus can be screened.

3. The mesh will not be blocked, the powder will not fly, and it can be sieved to 400 mesh or 0.028mm.

4. Fully enclosed structure, the powder does not fly, and the liquid does not splash.

5. Impurities and coarse materials are automatically discharged, and continuous operation is possible.

Mobile vibrating screen uses a vertical vibrating motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights, which convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen surface. Perform sieving. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Mobile vibrating screens usually consist of the following structures:

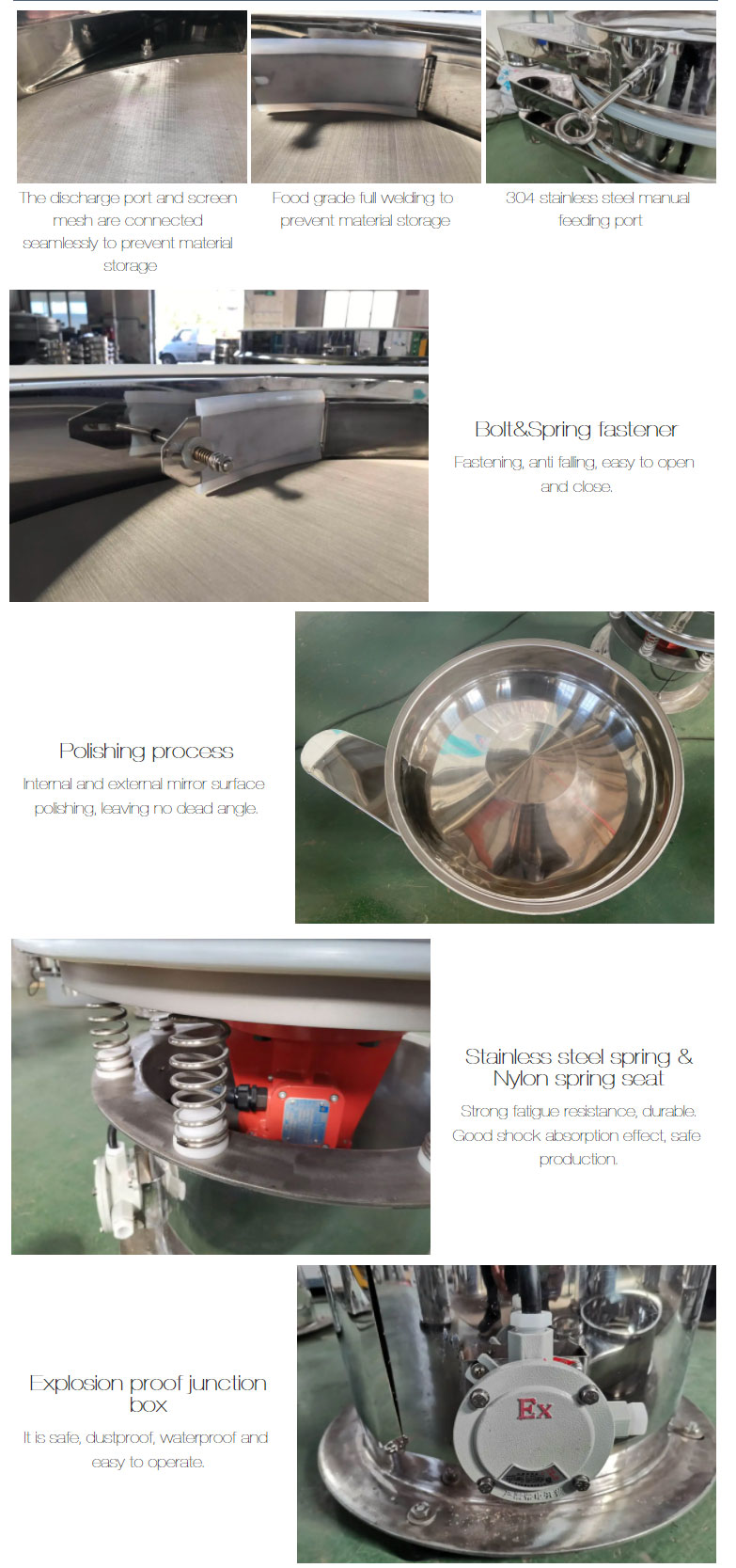

1. Sieve bed: The sieve bed is the most important part of the mobile vibrating screen. It usually consists of a cone-shaped bracket, a hanging device, a screen surface, and a material inlet and outlet.

2. Vibrators: Mobile vibrating screens generally use vibrating motors as the vibration source. They are divided into single-layer vibrators and double-layer vibrators, with different vibration modes and vibration intensities.

3. Support: The support of the mobile vibrating screen is not only an important part of supporting the screen bed, but also provides good transportation and moving conditions.

4. Control system: The control system of the mobile vibrating screen is usually composed of an electric control box, a vibration sensor and a regulator to ensure the screening effect and safety.

5. Other components: The mobile vibrating screen may also include dust-proof devices, cooling devices and cleaning devices, etc., to meet different screening requirements.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

1. Food industry

The choice of equipment is the most cautious, because the food industry requires high hygiene standards. Therefore, it is recommended to use stainless steel. The stainless steel mobile vibrating screen is made of 304 stainless steel, which is not easy to rust and will not pollute the screening materials.

2. Chemical industry

(1) For the screening of materials with less acidity, it is recommended to use: plastic material mobile vibrating screen, which is made of pp plastic material, which has strong acid resistance, so it is not a problem for acidic materials to be screened.

(2) For screening materials with strong alkalinity, it is recommended to use: plastic material mobile vibrating screen, not only suitable for acidic materials, but also for screening alkaline materials.

3. Paper industry

It has a sealed structure, so it can screen certain moisture-containing materials.

The frequency of the vibrating screen refers to the number of times the vibrating screen vibrates up and down per unit time, usually using HZ (Hertz) as the unit of measurement. The higher the frequency of the vibrating screen, the higher the screening efficiency, but it will also have a greater impact on the machine, thus affecting the service life of the machine. Generally speaking, the frequency of the vibrating screen is between 1200-3000HZ, which is adjusted according to the nature of the material and the screening requirements. For high-precision screening requirements, the frequency is usually higher, and for some coarse-grained materials, the frequency can be appropriately reduced to avoid excessive wear and energy waste.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.