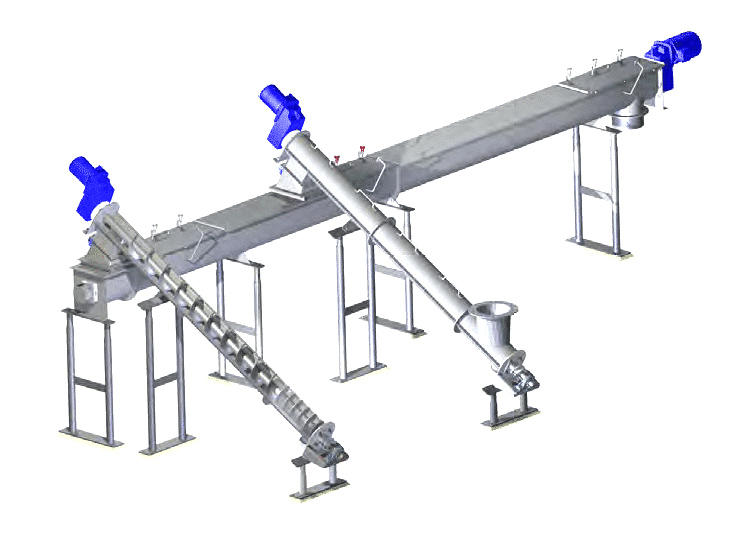

Convey bulk materials such as powders, granules and flakes from one location to another in a continuous and efficient manner.

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100mm-1250mm

Capacity: 458m³/h

Length: 2-70 meters

Angle of Inclination: 0-90°

Customized: shaft/shaftless, tubular/U-shape, single shaft/double shaft

Application: used for horizontal, vertical or inclined conveying materials, widely used in grain, free, feed, concrete production, sludge treatment and other industries

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Industrial screw conveyor is a mechanical conveying device used in various industries to move materials in a controlled manner. It consists of a helical screw blade, known as an auger, contained within a tube or trough. The rotation of the screw blade causes the material to move along the length of the conveyor from one end to the other.

Industrial screw conveyors are versatile and commonly used for handling bulk materials such as powders, grains, flakes, pellets, and granules. They are utilized in industries like agriculture, food processing, mining, chemical processing, pharmaceuticals, and more.

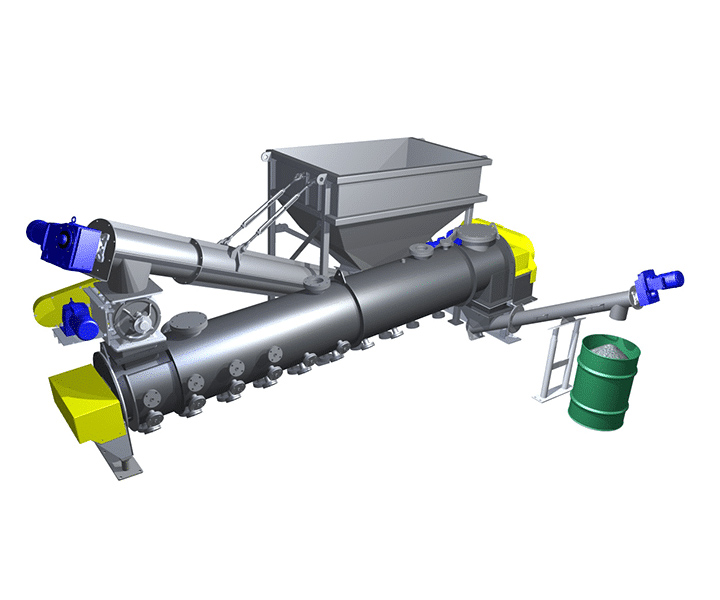

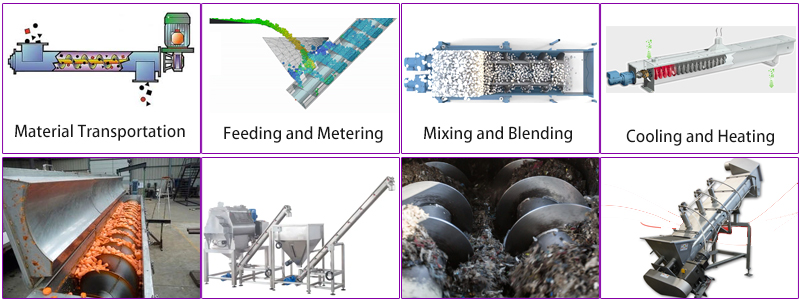

Industrial screw conveyors are versatile machines used to transport a wide range of bulk materials, both dry and wet. They are commonly employed in various industries, including food processing, manufacturing, agriculture, and construction.Here are the primary functions of industrial screw conveyors:

1.Material Transportation: The main function of a screw conveyor is to move bulk materials from one location to another. The rotating screw pushes the material along the trough, efficiently transporting it over varying distances and elevations.

2.Feeding and Metering: Screw conveyors can accurately feed materials into other processing equipment, such as mixers, dryers, or reactors. By controlling the conveyor's speed, it is possible to regulate the flow rate of the material.

3.Mixing and Blending: Screw conveyors can be used to mix and blend different materials together. By adjusting the screw's rotation speed and the composition of the materials being fed into the conveyor, it can create homogeneous mixtures.

4.Cooling and Heating: In some applications, screw conveyors can be used to cool or heat materials. By passing a cooling or heating medium through the conveyor's trough, it can alter the temperature of the material being transported.

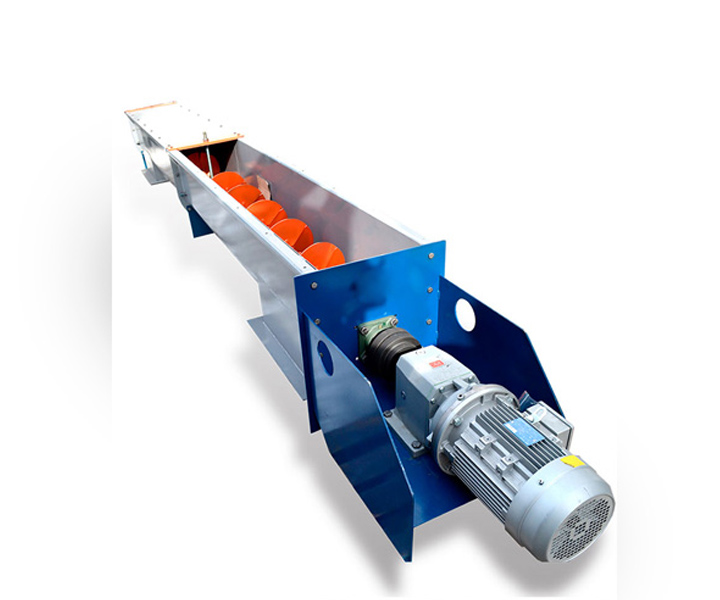

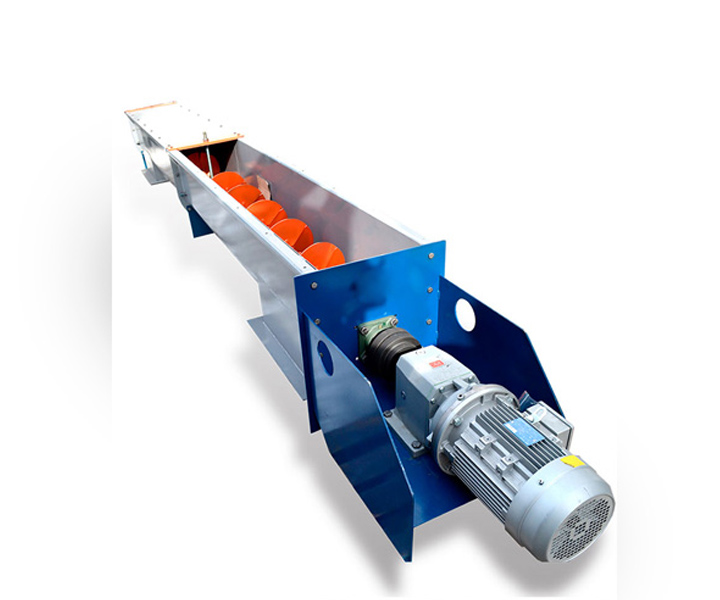

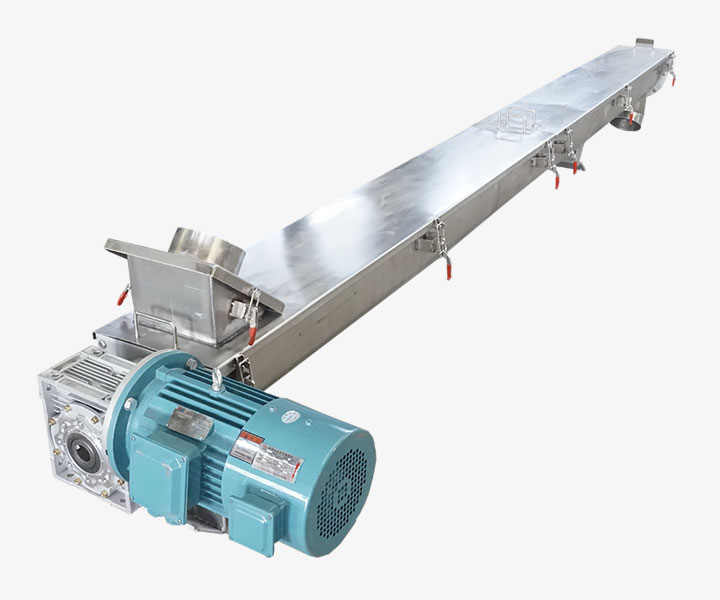

Tubular Screw Conveyor

Ideal for conveying dry or semi-fluid bulk materials in fully enclosed spaces, thereby reducing the threat of hazardous contamination, dust, spillage and subsequent waste, it can be conveyed from 0 to 90 degrees for flexible movement and transportation.

Shaftless Screw Conveyor

Bulk material discharged from centrifuges, filter presses or mixers can be easily conveyed. Our shaftless design provides a clog-free conveying surface, making difficult-to-convey materials easy to convey.

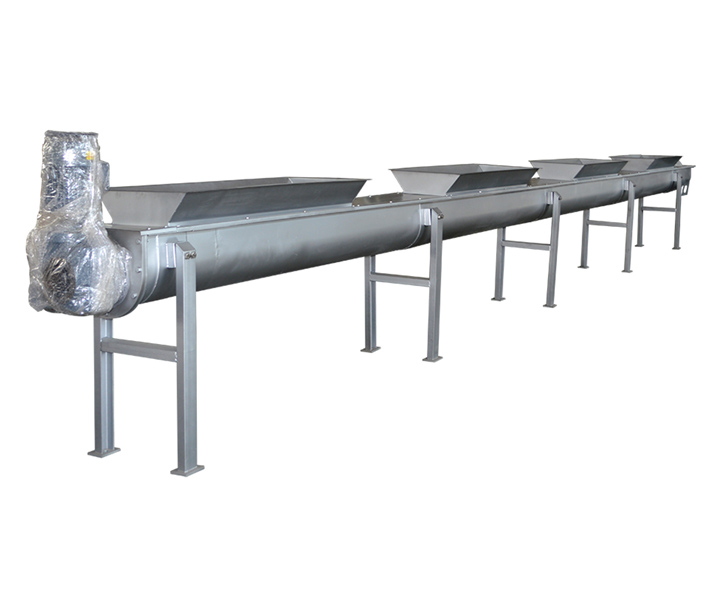

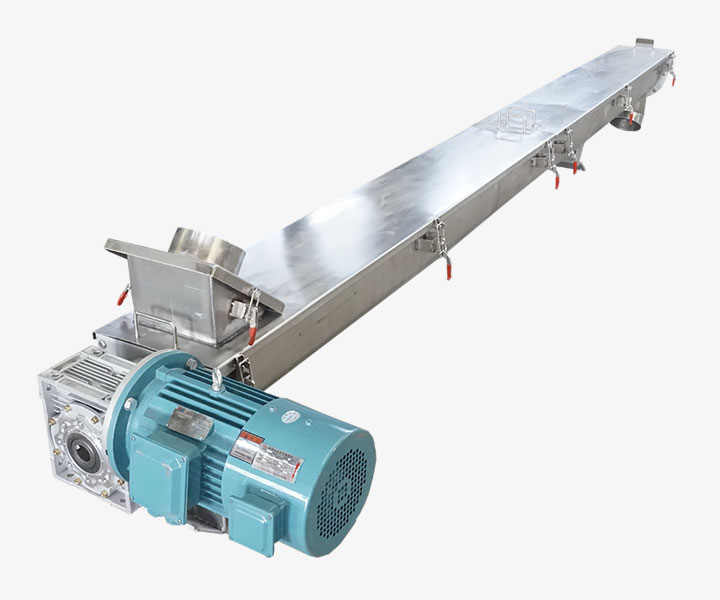

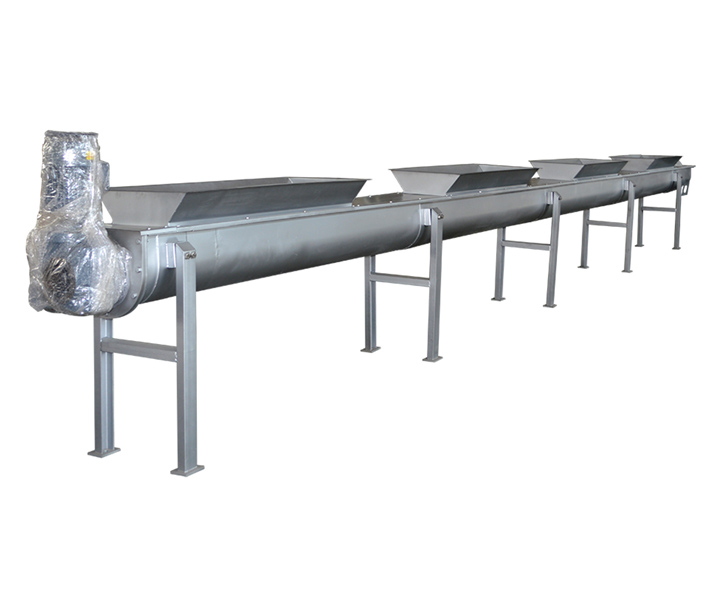

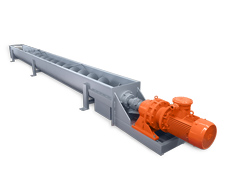

Trough Screw Conveyor

The product is conveyed horizontally/with a small inclination in the trough with a "U" cross-section. The machine cover can be disassembled at any time, which is convenient for observation and maintenance. In addition, single-point feeding or multi-point feeding can be used, and multi-point feeding can also be used. Click Unload.

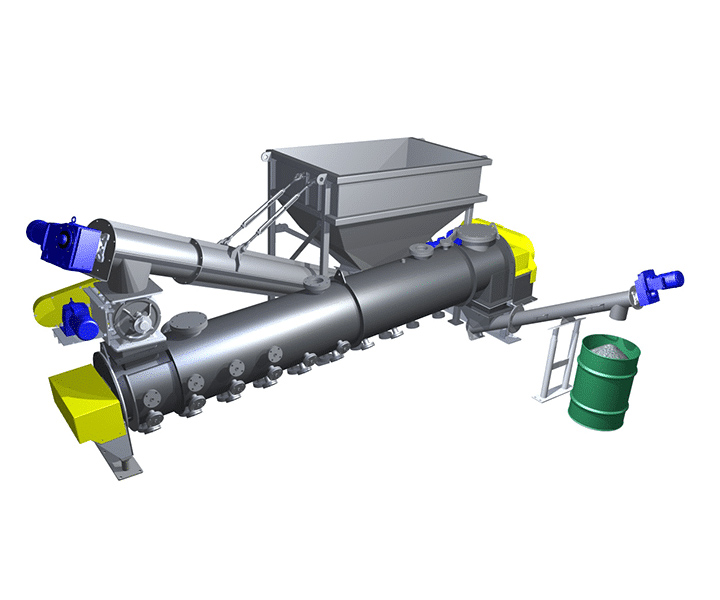

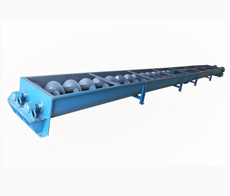

Double Screw Conveyor

There are two screw shafts installed, one is left-handed and the other is right-handed. The two screw shafts alternately rotate and convey back and forth, which can avoid material blocking caused by material accumulation, and have the function of mixing and stirring.

Cooling Screw Conveyor

Specifically designed to cool the material being conveyed through the conveyor, it can cool your product from 450 degrees Celsius to below 50 degrees Celsius, suitable for conveying high temperature slag, fly ash, coal cinder, rubber powder, carbon black, etc.

Lab Screw Conveyor

It is specially designed for small feed volume and laboratories, and is mainly installed under the silo or under the main screw feeder as a feeding device for chemical production and pharmaceuticals in laboratories or any process that requires precise and small volume delivery.

Versatility

Versatile and can be used to handle a wide range of materials including powders, granules and flakes. They can also be used for horizontal, inclined or vertical transport, depending on application requirements.

Energy saving

Industrial screw conveyors are energy efficient compared to other types of conveying systems such as belt conveyors or bucket elevators. They require less electricity to operate, helping to reduce energy costs.

Gentle handling

Designed to handle materials gently and without damage, ensuring a consistently high quality end product.

Dust-proof

Dust caps and seals can be designed to prevent contamination and maintain a clean and safe working environment.

Low maintenance

Compared to other types of conveyor systems, industrial screw conveyors are relatively simple in design and require minimal maintenance, reducing maintenance costs and downtime.

Custom made

Can be customized to meet application specific requirements including material properties, capacity and desired output rate. They can also be designed with different screw diameters, pitches and configurations to optimize material handling processes.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

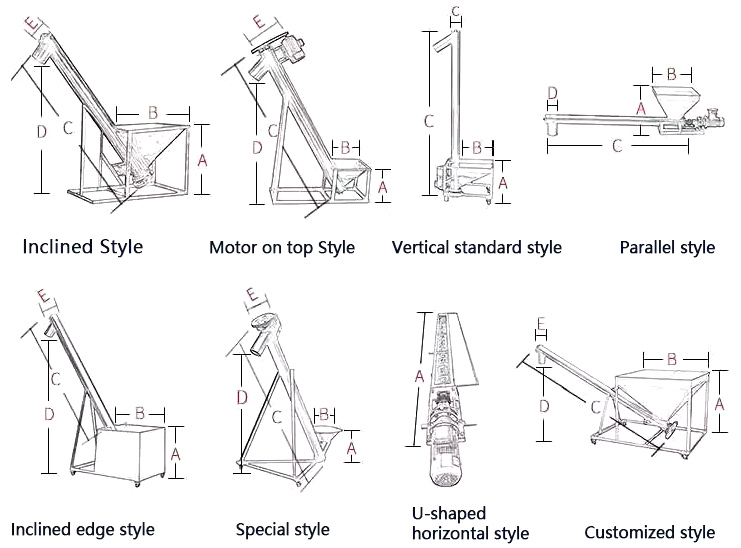

Industrial screw conveyors have various designs in different industries to meet the specific needs of different industries. The following are some common screw conveyor designs and their applications in different industries:

| Industry | Food processing industry | Chemical industry | Building materials industry | Agricultural industry | Mining industry | Solid waste industry |

| Special design | · Food-grade materials: used to convey food raw materials, powders, particles, liquids, etc. · Stainless steel structure: to meet food hygiene standards. · Clean design: easy to clean and avoid residue. |

· Corrosion-resistant materials: such as 316 stainless steel, etc., used to convey · chemical raw materials. · Sealing design: avoid leakage of harmful substances. · Explosion-proof design: suitable for flammable and explosive environments. |

· High-strength structure: used to convey heavy materials such as sand, cement, and stone. · Large capacity design: suitable for large-scale production. · Wear-resistant design: improve durability. |

· Rust-proof coating: prevent corrosion. · Adjustable height: adapt to different working occasions. · Dust-proof design: prevent dust pollution. |

· Ultra-large design: used to convey large-particle materials such as ore and coal. · Wear-resistant design: to cope with particle wear. · Efficient design: Increase production. |

· Sorting design: Used for the treatment and recycling of waste materials. · Closed design: Reduce pollution. · Energy-saving design: Reduce energy consumption. |

Design considerations

Material characteristics: Fully consider the particle size, density, viscosity, abrasiveness, corrosiveness, etc. of the material.

Conveying capacity: Determine the conveying capacity according to production needs and select the appropriate screw diameter and speed.

Conveying distance: Select the appropriate screw length and drive mode according to the conveying distance.

Conveying environment: Consider factors such as temperature, humidity, and dust in the working environment.

Safety: Use reliable sealing devices to prevent material leakage and personal injury.

Industrial screw conveyors can be customized in many ways to meet the specific requirements of different material handling applications. Here are some common customization options available:

1. Screw diameter: different screw diameters can be customized to suit different material handling capacity and flow.

2. Pitch: The pitch refers to the distance between the screw blades. Different pitches are available to optimize material flow and prevent material buildup or clogging.

3. Screw length: different screw lengths can be customized to meet the length requirements of the material conveying system.

4. Groove design: Different groove designs can be customized, including U-shaped and tubular designs. The trough design can be selected according to the specific requirements of the material being conveyed and the configuration of the material handling system.

5. Materials of Construction: Can be made from a variety of materials including carbon steel, stainless steel and other alloys. Structural materials can be selected according to the specific requirements of the conveyed materials and the use environment.

6. Accessories: Various accessories can be customized for the screw conveyor, including dust removal system, discharge chute, and feed hopper. Accessories can be selected according to the specific requirements of the material handling system.

| Material | Feed hopper | Auger | Drive |

| carbon steel | flange connection ring | conventional | fixed speed |

| carbon steel painted | Standard size | Shaftless | variable speed |

| Stainless Steel Type 304 | cone | ribbon | Explosion-proof |

| Stainless Steel 316L Type | square | dentate | water proof |

| Manganese steel | multiple | paddle | Special custom |

| other | other | other |

The operation of industrial screw conveyor involves the rotation of the screw, which moves the material along the trough. As the screw rotates, the material is pushed forward or upward depending on the design and orientation of the conveyor. The helical flighting acts as a continuous spiral that creates a positive displacement, effectively moving the material in a controlled manner.

1.Agriculture and food processing: Screw conveyors are used to transport grain, feed and granular agricultural products. They can transport grain from storage warehouses or unloading areas to processing equipment or packaging lines.

2.Chemical and pharmaceutical: Screw conveyors are used to transport powders, granules and granular chemicals or pharmaceuticals. They can transport raw materials to reactors, mixers, dryers or packaging equipment during the production process.

3.Food processing and packaging: Screw conveyors are widely used in the food processing and packaging industries. They can be used to convey materials such as flour, powdered sugar, spices, vegetables and fruits.

4.Construction and material handling: Screw conveyors can be used for material transportation in construction sites and material handling facilities. They can transport materials such as concrete, sand, gravel, cement, etc. from one location to another.

5.Water treatment and waste treatment: Screw conveyors play an important role in sewage treatment plants and waste treatment facilities. They can be used to transport materials such as sludge, solid waste, sewage treatment residues, etc.

6.Waste Disposal and Recycling: Screw conveyors are used for waste handling in waste disposal and recycling facilities. They can transport waste from sorting tables to compactors, incinerators or recycling equipment.

Industrial screw conveyors are currently widely used in food processing, chemical, building materials, agriculture, mining, environmental protection and pharmaceutical industries to transport various raw materials, powders, granules or waste materials to achieve efficient and reliable material transportation and processing.

Below we will show the diverse functions of screw conveyors through some specific application examples.

Grain conveying: conveying wheat, corn and other grains from storage to the grinding workshop.

Flour conveying: conveying flour from the sifter to the mixer.

Sugar conveying: conveying sugar from the packaging machine to the storage tank.

Batching system: conveying raw materials of different proportions to the mixer for batching.

Chemical powder material conveying: conveying powder materials such as plastic particles, dyes, fertilizers to the reaction Cement conveying: conveying cement from the mill to the packaging machine.

Sand and gravel conveying: conveying sand and gravel from the silo to the concrete mixer.

Mineral powder conveying: conveying mineral powder from the crusher to the ball mill.

Grain conveying: conveying grain from the harvester to the dryer or storage bin.

Feed conveying: conveying feed from the batching machine to the farm.

Fertilizer conveying: conveying fertilizer from the packaging machine to the fertilizer applicator.

Garbage disposal: conveying garbage, sludge, etc.

The industrial screw conveyor produced by Dahan has a complete range of models and various types. The type can be selected according to the customer's working environment. It supports material transportation in horizontal, vertical, and inclined displacement directions. The material can withstand a high temperature range and can be below 200 degrees. Generally speaking, the inclination angle of the screw feeder can reach 15~25 degrees, conveying powdery, granular and small block materials, such as cement, coal powder, grain, chemical fertilizer, ash, sand, etc., the length can be from 4 meters to 70 meters, every 0.5 meters, the transmission efficiency can reach 8-112t/h.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.