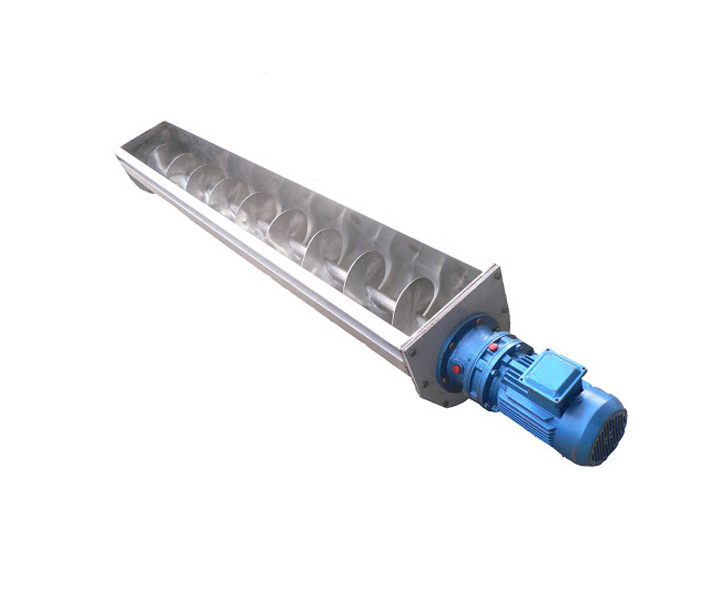

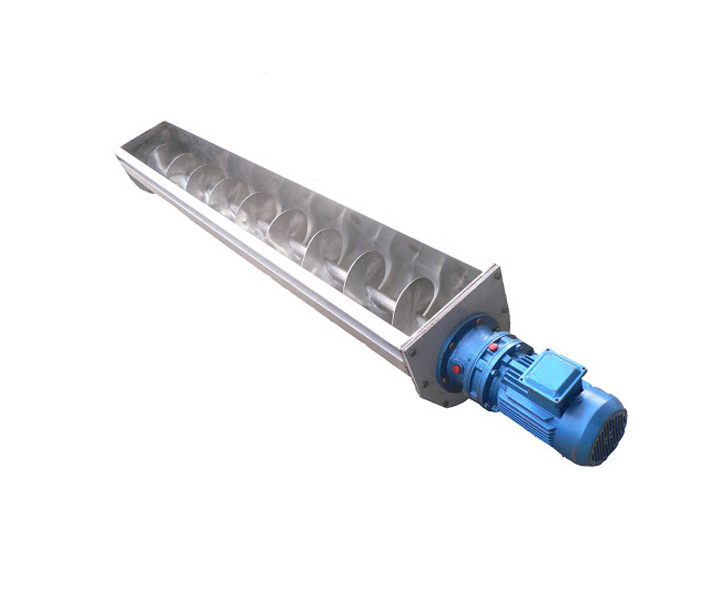

Stainless steel screw conveyor

Stainless steel screw conveyor Stainless steel trough screw conveyor

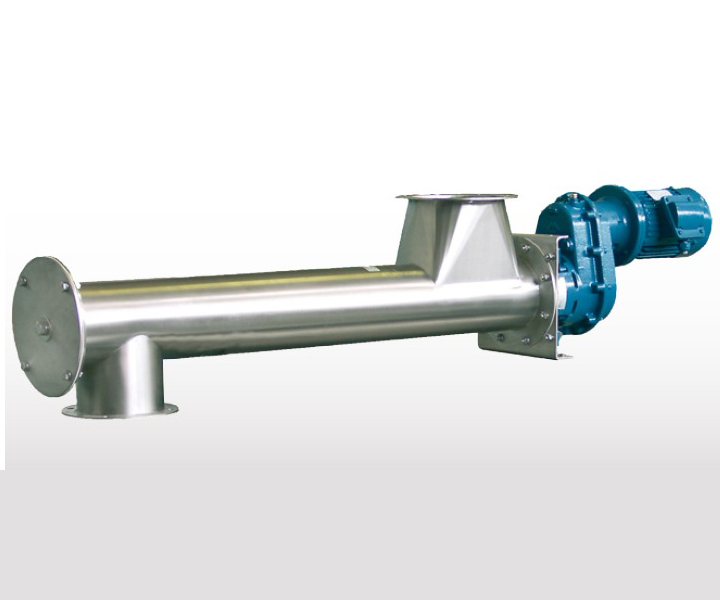

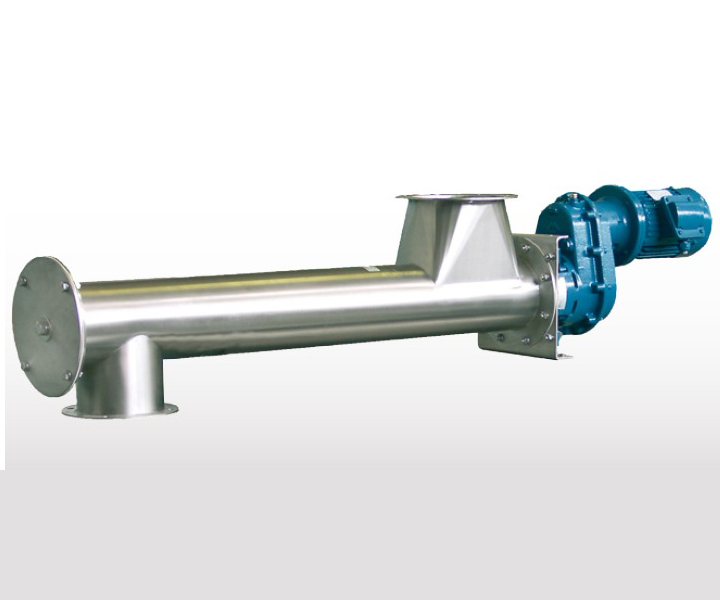

Stainless steel trough screw conveyor Stainless steel screw feeder

Stainless steel screw feeder Stainless steel vertical screw conveyor

Stainless steel vertical screw conveyor stainless steel spiral

stainless steel spiral

Used in food, medicine and sewage sludge treatment industries to transport clean and corrosive materials

![]()

![]()

Price:$600.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100mm-1250mm

Output: 9-134.2 tons/hour

Length:2-70 meters

Speed: 20-150rpm

Optional material:SS304 or 316L stainless steel

Applicable materials: flour, salt, monosodium glutamate, traditional Chinese medicine powder, western medicine powder, various feeds, etc.

Application industry: food, condiment, medicine, grain, feed, etc.

Commitment:

Stainless steel screw conveyor is made of 304 or 316 stainless steel, designed for food or pharmaceutical industries. Washable and sterilizable, resistant to corrosion and avoiding material contamination, it provides a variety of solutions for conveying or feeding powdery or granular materials. They are suitable for applications where any contamination of the material handled must be strictly avoided and where absolute cleanliness and perfect corrosion resistance are required, such as in environmental technology, flour and animal feed processing, food processing and packaging, plastics and chemicals, and the pharmaceutical industry.

Stainless steel screw conveyors are commonly used in various industries for transporting bulk materials, such as grains, powders, and chemicals. Here are some optional materials that can be used for stainless steel screw conveyors:

304 Stainless Steel: 304 stainless steel is a common material used for screw conveyors. It is a low-carbon stainless steel that is resistant to corrosion and can withstand high temperatures. 304 stainless steel is suitable for most applications and is a cost-effective option.

316 Stainless Steel: 316 stainless steel is a higher grade of stainless steel that is more resistant to corrosion than 304 stainless steel. It is suitable for applications where the screw conveyor will be exposed to harsh chemicals or environments. 316 stainless steel is more expensive than 304 stainless steel.

The following will introduce you to two commonly used stainless steel materials:

| Comparison item | 304 stainless steel screw conveyor | 316L stainless steel screw conveyor |

| High temperature performance | It can withstand high temperatures of 800 degrees, but it performs poorly around 800 degrees | 316L stainless steel screw conveyor contains molybdenum, so it is suitable for high temperature and strong corrosion industries. 316L stainless steel can be used normally at high temperatures of 1200-1300 °C. |

| Corrosion resistance | Below 316L stainless steel | 316L stainless steel reduces the content of chromium in the material and increases the content of nickel element so that the corrosion resistance is higher than that of the screw conveyor made of 304 stainless steel. |

| Ease of cleaning | They are quick to clean, but they will corrode the surface and eventually cause the 304 stainless steel pipe to rust | With high stability, it can effectively extend the service life of equipment and reduce equipment maintenance costs |

| Stable performance | Once scratched, there will be rust problems | The surface is smooth. During the production process, the surface of the vibrating screen will not absorb materials. After the production is completed, it is easy to clean and save equipment maintenance time. |

Stainless steel screw conveyors are used in various applications in industries such as food processing, agriculture, chemical and pharmaceutical, following are some common features of stainless steel screw conveyors:

Bulk Material Conveying: Commonly used to transport bulk materials such as grain, powder and chemicals, they can be efficiently and reliably moved from one location to another.

Mixing and agitation: It can be used for mixing and mixing materials, and a special mixing screw or agitator can be designed to ensure that the materials are fully mixed.

Drying: Material can be dried by conveying it through a heated chamber, which can be designed with hollow spirals to allow steam or hot air to circulate through the conveyed material.

Cooling: The material can be cooled by conveying it through a cooling chamber, which can be designed with a hollow spiral to allow cool air or water to circulate through the conveyed material.

Feeding and Discharging: Can be used to feed or discharge material from a processing system and can be designed to regulate the flow of conveyed material.

Here are some industries where stainless steel screw conveyors are commonly used:

Food processing industry: used for handling, mixing and transporting foods such as grains, flour, sugar and spices, the stainless steel structure ensures safe and hygienic transport of food.

Agriculture: Used in agriculture to handle and transport grain, feed, and other agricultural products, for truck loading and for transporting materials within processing facilities.

Chemical industry: Used in the chemical industry for handling and transporting powders and other bulk materials such as fertilizers, dyes and pigments, stainless steel construction ensures corrosion resistance.

Pharmaceutical industry: For handling and transporting powders, granules and other bulk materials used in the manufacture of pharmaceutical products, stainless steel construction ensures safe and pollution-free material transport.

Waste management industry: Used in the waste management industry to process and transport waste such as sludge, biosolids and compost, corrosion-resistant, rust-resistant and easy to clean.

Stainless steel screw conveyor for conveying salt

Stainless steel trough screw conveyors for conveying sludge

Clean and hygienic

The 304 or 316 stainless steel material is polished and will not rust, which can avoid pollution to the conveyed materials and the environment.

Acid and alkali corrosion resistance

Due to the use of 304 or 316 stainless steel, it has good wear resistance and corrosion resistance, and can be used in industries with strong acid and alkali.

200℃ high temperature resistance

It can transport dry powder and wet powder such as 200℃ powder, granule and small block materials.

Easy to clean

There is a discharge valve at the lower end of the feeding port, and the screw can be reversed to discharge, so the discharge and cleaning are very convenient.

Various soft connections

The inlet and outlet can be connected by universal joints, cloth bags and flanges, and can also be combined with butterfly valves and plug-in valves produced by our factory, which can be flexibly applied to sewage in grain, chemical, pharmaceutical, food or environmental protection projects. Sludge treatment site.

Sealing system

The completely sealed environment has great advantages for occasions with large dust and environmental requirements, which can avoid the generation of dust during the conveying process.

Screw conveyors are mainly made of Q235 carbon steel, SUS304 or 316L stainless steel and plastic. The following table will show you the differences between screw conveyors made of different materials:

| Comparison Item | Carbon Steel Screw Conveyor | Stainless Steel Screw Conveyor | Plastic Screw Conveyor |

| Material | Q235 carbon steel | SUS304 or 316L stainless steel | PolypropylenePP |

| Application | It is mainly used in cement, coal, stone and other industries with high wear and no special requirements for sanitation. | Dry and wet materials, slurries and pastes, for a variety of industries including food processing, chemical, pharmaceutical and waste treatment. | It solves the problems of Q235 ordinary carbon steel and SUS304 stainless steel that are prone to oxidation and corrosion after contact, and ensures that the materials will not deteriorate during the screening process, suitable for highly corrosive chemical industries. |

| Corrosion resistance | Does not have anti-corrosion ability, easy to rust | Resistant to air, steam, water and other weak corrosive media, not easy to rust | Strong corrosion resistance, no reaction with acid and alkali |

| Durability | Durable, single deformable | High tensile strength, extremely durable | Not wear-resistant, easy to accumulate dirt |

| Cleanliness | Do not have | Easy to clean and maintain, does not trap bacteria or other contaminants, and is easy to sanitize | Do not have |

| Temperature | Around 500 degrees Celsius | Around 800 degrees Celsius | Below 155 degrees Celsius |

| Cost | Lowest | Highest | Second only to stainless steel |

Classification by conveying direction:

Horizontal screw conveyor: uses a U-shaped trough. When the conveyor is working, the material enters the feed port from one end along the displacement direction and is discharged from the middle or other end. It is suitable for conveying large quantities of materials or mixed materials, and the horizontal screw conveyor is a low-speed, short-distance conveyor.

Vertical screw conveyor: suitable for conveying materials vertically 90° upward, with a small footprint and low manufacturing cost. The disadvantage is that the conveying volume is small and the conveying height generally does not exceed 8 meters. It can quickly lift general bulk solid materials vertically.

Inclined screw conveyor: The inclination angle is between 45 degrees. It should be noted that with the increase in the degree of inclination, the gravity of the conveyor will increase, resulting in a decrease in conveying efficiency. The solution is to increase the motor power or the thickness of the pipe wall.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The specifications of this product are (tube type, U type) (single shaft, no shaft), and can be reasonably selected and designed according to the particle size, conveying volume, and conveying distance of the conveyed material, so that there is no material jam, no arching, and smooth discharge. , Provide parameters and drawings for free.

Stainless steel screw conveyor manufacturers will help you select and design according to some parameters such as working conditions, material temperature, material particle size, material corrosiveness, material conveying volume, and material conveying distance. Reasonable design and selection of conveying capacity, shell material (201, 304, 316), motor matching power, and reducer matching speed are based on the principle of meeting user needs.

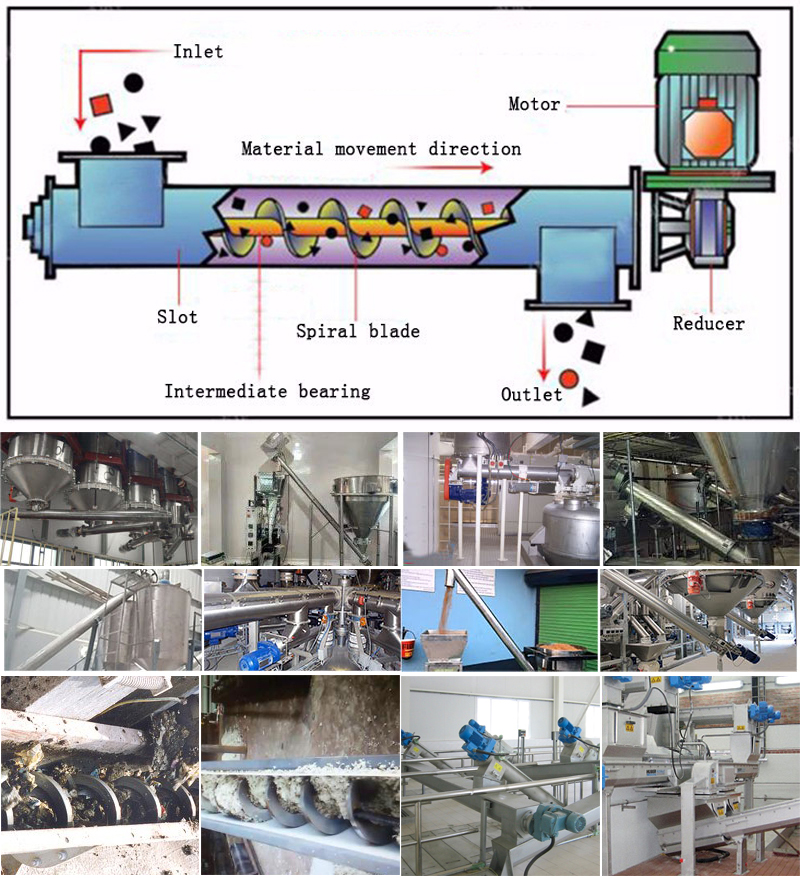

Spiral: It is usually made of stainless steel and designed in a spiral shape that allows the screw to convey material from one end to the other. Screw pitch, diameter and length can be customized according to specific application requirements.

Tube: The tube is the casing that surrounds the screw. It is usually made of stainless steel and can be designed in various shapes and sizes according to specific application requirements.

Drive system: It usually consists of a motor, gearbox and coupling. The motor provides the power to turn the screw, while the gearbox and coupling help transmit the power from the motor to the screw.

Inlet and outlet: The inlet and outlet are the openings at both ends of the screw conveyor. The feed port is used to feed the material into the screw conveyor, and the discharge port is used to discharge the material from the screw conveyor.

Hanger Bearings: Hanger bearings are used to support the screw and prevent it from bending or deflecting. They are usually made of stainless steel and can be designed in various shapes and sizes according to specific application requirements.

Seals: Seals are used to prevent leakage of material from the screw conveyor. They are usually made of rubber or another flexible material and sit at the end of the tube.

How Stainless Steel Screw Conveyor Helped Different Industries:

Transport Salt

It is widely used in the production of powder washing salt. In production, it is easy to use, low maintenance rate, reliable, clean and hygienic, and meets food-grade standards.

Feeding of Tea

Unprocessed tea leaves are usually packaged in large bags and need to be fed into a closed system. Dahan Machinery has developed a special hopper for this purpose. Material can be fed from both sides at the bag loading and unloading station if necessary.

The material of Xinxiang Dahan stainless steel screw conveyor is divided into 304 and 316L stainless steel. The appropriate material can be selected according to the conveyed material. It is mostly used in industry, food and pharmaceutical industries. Shuzhong Pharmaceutical Co., Ltd., Shanghai Jiage Food Co., Ltd., Sunflower Pharmaceutical Group, Coca-Cola, etc. In addition, our conveyors can also be customized according to customer's on-site requirements, such as: lengthened design, different inclination angles, the size of the feed inlet, the addition of a hopper at the feed inlet, and the installation of moving wheels, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.