Horizontal belt conveyor

Horizontal belt conveyor Mobile horizontal belt conveyor

Mobile horizontal belt conveyor Small horizontal belt conveyor

Small horizontal belt conveyor Horizontal rubber belt conveyor

Horizontal rubber belt conveyor Stainless steel horizontal belt conveyor

Stainless steel horizontal belt conveyor

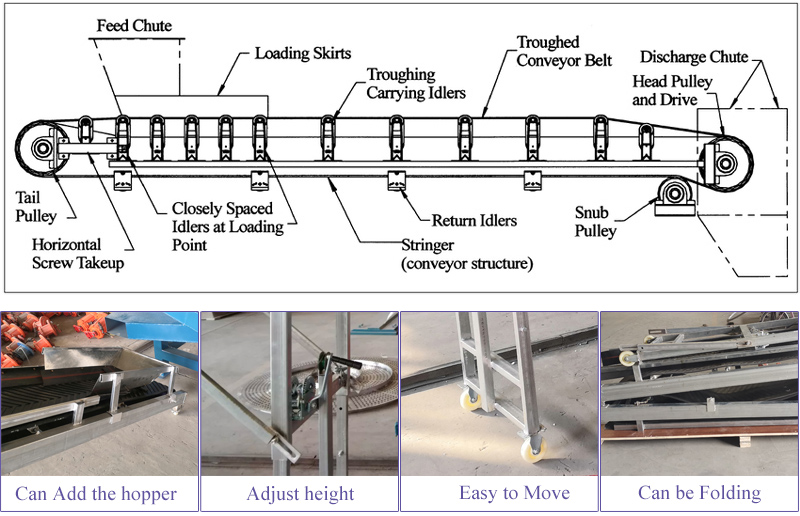

The material can be transported from the feeding point to the unloading point in the horizontal direction

![]()

![]()

![]()

Price:$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt Width: 400/500/650/600/800/1000/1200/1500mm

Conveying length: 10-30 meters

Conveying capacity: 30-3000t/h

Conveying speed: 1.25-2.0m/s

Voltage: 380V

Power: 0.4kW - 22kW

Application: Continuous or intermittent motion to transport various products, not only can transport various bulk materials, but also various cartons, packaging bags and other items with a small weight

Commitment:

Horizontal belt conveyor is a conveyor system that uses belts to transport goods or materials horizontally from one point to another. Commonly used in a variety of industries, including manufacturing, distribution, and logistics, to transport goods or materials from one location to another. They are typically used in applications that require moving products or materials over long distances or with multiple processing points along the way.

Conveyor belts with different bandwidths can be selected according to the customer's demand for conveying capacity. The hourly processing capacity: bulk grain 50-200 tons/hour, packaged grain 1200 bags/hour, common belt widths are 550mm, 650mm, and 800mm, which can be customized according to site requirements. Install moving wheels for easy movement.

Horizontal belt conveyors are used in a wide variety of industries and applications to transport goods or materials horizontally from one place to another. Here are some common applications for horizontal belt conveyors:

Manufacturing: Typically used in manufacturing facilities to transport products or materials between different processing points such as assembly lines or workstations.

Distribution: Used in distribution centers to transport boxes, packages, and other goods from one location to another, such as from a sorting area to a loading dock.

Warehousing: Used in a warehouse to transport goods or materials from one location to another, such as from a storage area to a shipping area.

Food processing: Used in food processing facilities to transport food between different processing points, such as from a washing area to a packing area.

Mining: Used in mining operations to transport bulk materials such as ore or coal from one area to another.

Agriculture: Used in agriculture to transport crops or other materials between different processing points, such as from a harvesting area to a storage area.

Horizontal belt conveyor is a machine that uses friction drive to continuously transport materials. It is composed of two end rollers and a closed conveyor belt tightly sleeved on it. The roller that drives the conveyor to rotate is called the drive roller; there is also a roller that can change the direction of movement of the conveyor belt is the redirecting roller. The drive roller is driven by the motor through the reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end, which can increase the traction and facilitate dragging. The items are fed from the feeding end, fall on the rotating conveyor belt, and are discharged from the unloading end of the conveying bag by the friction of the conveyor belt.

Horizontal conveying

It can be used for short-distance horizontal transportation and loading and unloading in bulk or in single pieces, with a piece weight of 100 kg.

Wasy to move

The bottom of the horizontal belt conveyor is equipped with universal wheels, which can be moved anywhere.

Height adjustable

The lower leg adopts an adjustable lifting leg, the height can be adjusted at will, and the length is 3 to 12 meters in length. The height rises and falls at 1.2-4 meters.

Foldable

It is foldable and easy to store and carry. One person can easily move and fold it. It is mostly used in the transportation, loading and unloading of bagged materials.

Horizontal belt conveyor for grain loading

Horizontal belt conveyor for loading in brick factory

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Horizontal belt conveyor is mainly composed of fixed frame, roller, idler, motor, bridge shaft, universal wheel and distribution box.

Rack: The upper and lower parts of the rack are welded with hollow square steel as a whole, which becomes the main body of the conveyor. The empty square steel pipes on both sides of the lower part of the frame play the role of guide rails, and there are side conduits on both sides of the upper part.

Transmission part: start the motor, the motor pulley drives the pulley at one end of the bridge shaft to rotate the bridge shaft, and the pulley at the other end of the bridge shaft drives the pulley on the main drive roller shaft to make the main drive roller rotate and drive the conveyor belt to run.

Rollers and idlers: There are four rollers in the horizontal belt conveyor. One main drive roller is installed in the middle of the frame; three reversing rollers are installed in the middle of the frame, one at the head and one at the end, and the rollers are all made of steel.

Tensioning device: A tensioning device is installed at the bearing seat where the reversing roller, head and tail rollers are installed, which is used to tension the conveyor belt and adjust the deviation of the conveyor belt.

Distribution box: The gas control box is equipped with a switch device to control the operation of the motor, which is used to control the continuous operation of the conveyor.

The conveyor belt of Dahan horizontal belt conveyor adopts rubber, silicone, PVC, PU, etc., in addition to the conveying of ordinary materials, it can also meet the transportation of materials with special requirements such as oil resistance, corrosion resistance and anti-static. It can not only transport broken and bulk materials, but also transport items in pieces. It can be transported by a single unit, or it can be composed of multiple units or a horizontal or inclined conveying system with other conveying equipment.

Xinxiang Dahan Belt Conveyor Manufacturer is a direct-selling enterprise integrating R&D, production, sales and service. It has its own labor and production team. All the projects undertaken are self-constructed by the company, without subcontracting, to ensure quality and product quality. The price is cheap, the standard parts are in stock, and the special order is shipped within 7 working days.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.