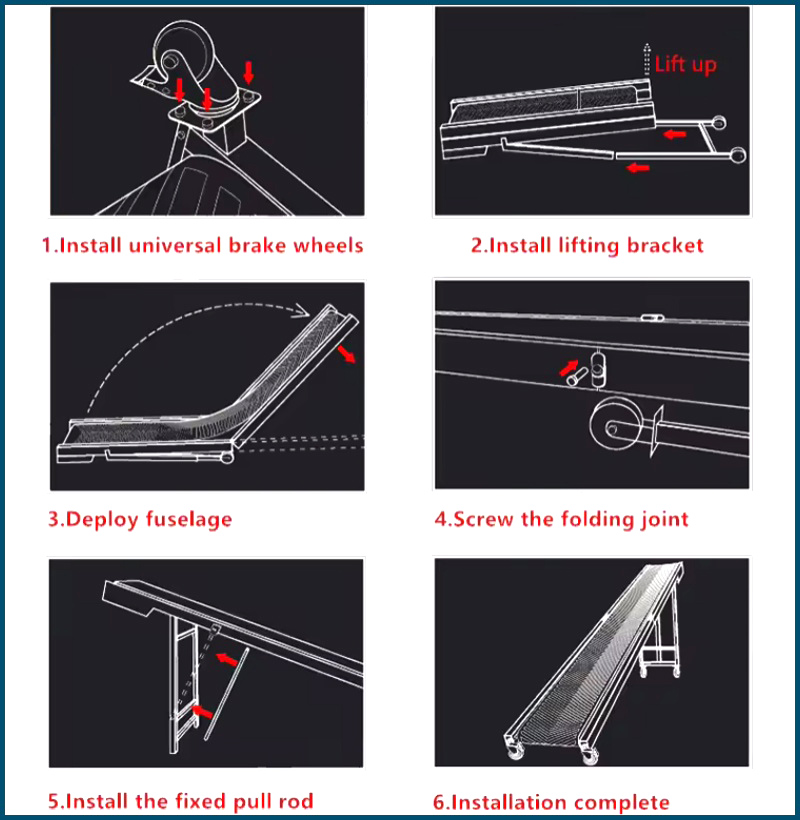

Easy to fold and unfold, it can be easily transported, stored and deployed as needed.

![]()

![]()

Price::$800.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Belt width: 400/500/650/600/800/1000/1200/1500mm

Climbing angle: 0°-90°

Conveying speed: 1.25-2m/s

Conveying length: 10 meters

Belt material: PVC/PU rubber

Frame Material: Carbon Steel/Stainless Steel

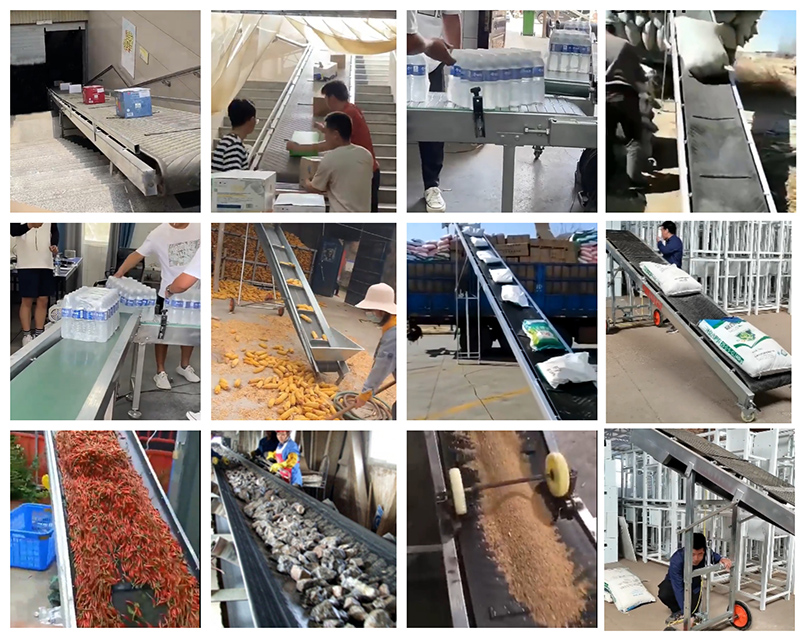

Application: Suitable for all types of materials including bulk materials, bags, boxes and packaged goods. They can be used to load and unload trucks, store materials or transfer materials between different stages of processing.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Folding belt conveyor is a conveyor system designed with a folding mechanism that can be folded or folded when not in use for easy storage or transportation. This design allows for greater flexibility and versatility in material handling applications where space savings and portability are critical.

Folding belt conveyors typically have an adjustable length, allowing users to extend or retract the conveyor to suit the specific requirements of the application. This flexibility enables the conveyor to be used in various settings and configurations. Can be used in a variety of industries and applications, including warehouses , distribution centers, manufacturing facilities, etc. They are suitable for conveying various types of materials such as boxes, parcels, bags and bulk items.

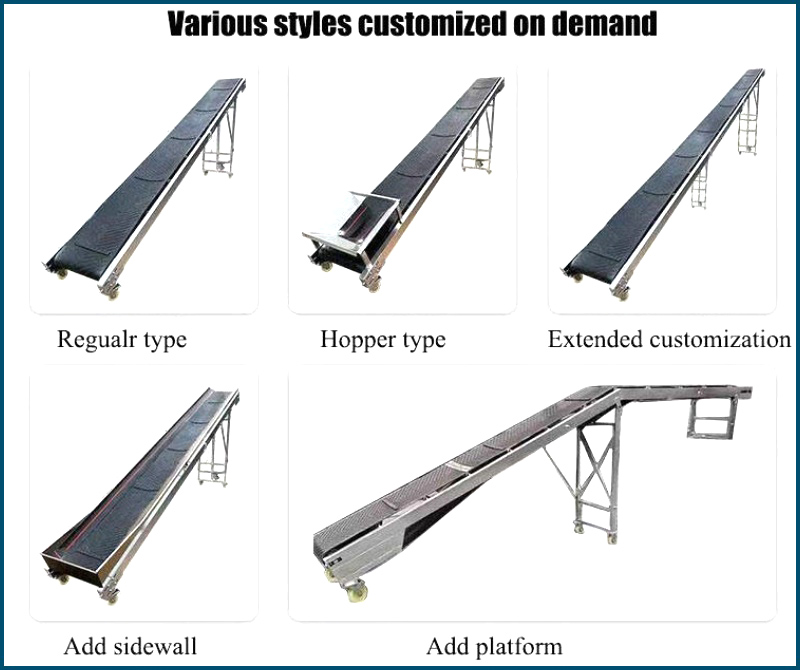

Regular folding belt conveyor: It has a foldable conveyor belt structure, suitable for general material transportation, high flexibility, and the length can be adjusted as needed.

Folding belt conveyor with hopper: A hopper is set on the conveyor belt, suitable for conveying granular materials and improving conveying efficiency.

Extended customization folding belt conveyor: The length and function are customized according to customer needs, suitable for material transportation in special scenarios.

Add sidewall folding belt conveyor: Side walls are set on both sides of the conveyor belt to prevent material overflow, suitable for the transportation of powdered or granular materials.

Add platform folding belt conveyor: A platform is set on the conveyor belt to facilitate operators to stand or work, suitable for scenarios requiring manual intervention.

Folding belt conveyors are suitable for a variety of industries and environments where portability and flexibility are essential for efficient material handling. Some common applications for folding belt conveyors include:

1. Warehousing and Distribution: Facilitate the movement of goods between different areas, such as loading docks, storage areas, and truck trailers. The ability to fold and transport the conveyor can be easily set up and reconfigured according to changing operational requirements.

2. Agriculture: For tasks such as loading and unloading grain, seeds or other agricultural products. They can be used in silos, storage sheds or directly on the farm to facilitate efficient material transfer. The portability of folding conveyors allows farmers to transport them between different fields or storage areas as needed.

3. Retail: Can be installed in temporary workstations or assembly lines to simplify the movement of products during peak or seasonal demand. The folding and transporting capabilities of the conveyor belt make it convenient for use in pop-up stores or temporary retail spaces.

Foldable

Folding belt conveyors are designed to fold and unfold easily for quick and easy transportation between locations or job sites.

Save space

When not in use, the folding belt conveyor folds compactly, minimizing the storage space required.

Adjustable length

Folding belt conveyors often have adjustable lengths, allowing the user to extend or retract the conveyor as needed. This flexibility allows the conveyor to adapt to different material handling tasks or different distances between loading and unloading points.

Folding belt conveyor

Typically features a user-friendly folding mechanism that allows operators to quickly unfold and assemble the conveyor without the need for special tools or extensive training.

Versatility

Suitable for all types of materials including bulk materials, bags, boxes and packaged goods. They can be used to load and unload trucks, store materials or transfer materials between different stages of processing.

Efficiency

Folding belt conveyors simplify material handling processes by offering a flexible, adaptable solution that can be easily adjusted to meet changing operational needs.

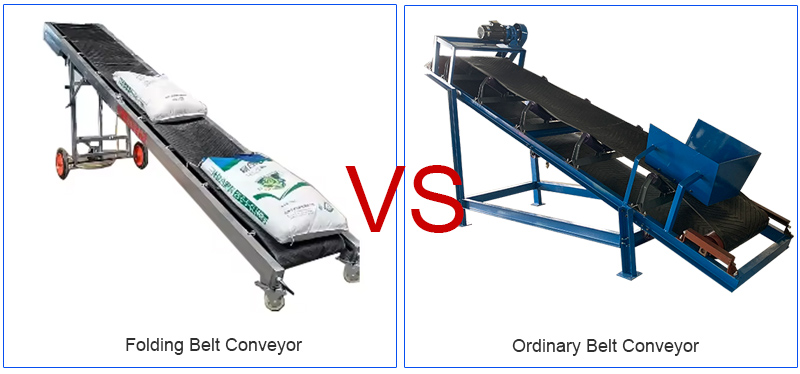

The main difference between a folding belt conveyor and an ordinary belt conveyor lies in their design and functionality. Here are some key distinctions:

| Comparison item | Folding Belt Conveyor | Ordinary Belt Conveyor |

| Portability and Folding Mechanism | Specially designed with a folding mechanism allowing it to be easily transported and stored in a compact form. | It has no folding mechanism and is usually permanently installed in a facility or production line. |

| Space-saving | Takes up less storage space. | The layout is fixed and requires dedicated installation space. |

| Adjustability | Typically have an adjustable length, allowing the user to extend or retract the conveyor as needed. | Usually have a fixed length and are not easily adjustable. |

| Transportability | Due to its folding mechanism and portability, folding belt conveyors are better suited for temporary or mobile applications that require frequent relocations. They can be easily transported by truck or trailer to different job sites. | Ordinary belt conveyors are typically designed for permanent installation within a facility and are not suitable for frequent relocations. |

| Application Flexibility | Commonly used in industries such as construction, agriculture, mining and warehousing where portability and space saving are critical. They are ideal for tasks such as truck loading and unloading, storing materials, or transferring materials between locations. | More commonly found in fixed production lines or facilities where continuous material handling is required. |

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

The structure of a folding belt conveyor typically consists of the following components:

Frame: The frame forms the main structure of the conveyor and provides support for the other components. It is typically made of steel or aluminum to ensure strength and durability. The frame may have a modular design, allowing for easy assembly, disassembly, and folding of the conveyor.

Conveyor Belt: The conveyor belt is an essential component that carries and transports the materials along the conveyor. It is typically made of durable and flexible materials such as rubber, PVC, or fabric. The belt is looped around pulleys or rollers at each end of the conveyor, and it can be adjusted in length to accommodate different material handling requirements.

Drive System: The drive system powers the movement of the conveyor belt. It typically consists of an electric motor, gearbox, and pulleys or sprockets that transmit power to the belt. The drive system can be located at one end of the conveyor, and it may include controls for adjusting the belt speed and direction.

Folding Mechanism: The folding mechanism is a key feature of a folding belt conveyor. It allows the conveyor to be folded or collapsed for easy transportation and storage. The folding mechanism typically involves hinges or joints in the frame that enable the conveyor sections to be folded or unfolded as needed. Some folding conveyors may have a telescopic design, allowing for adjustable length in addition to folding capability.

Support Legs or Stands: Folding belt conveyors often feature support legs or stands to provide stability and elevation for the conveyor. These legs are adjustable to accommodate different working heights and uneven surfaces. They are typically equipped with locking mechanisms to secure the conveyor in the operational position and prevent accidental folding or collapsing during use.

Idlers or Rollers: Idlers or rollers are used to support and guide the conveyor belt along its path. They are positioned at regular intervals underneath the belt to minimize friction and ensure smooth movement. Idlers or rollers can be fixed or adjustable to maintain proper tension and alignment of the belt.

Safety Features: Folding belt conveyors may incorporate various safety features to protect operators and prevent accidents. These features can include emergency stop buttons, safety guards, and sensors that detect obstructions or abnormal operation. Safety considerations should be an integral part of the conveyor design to ensure compliance with applicable safety standards.

A large logistics company faced space constraints and flexibility requirements in the material transportation process, and sought a solution that could efficiently transport materials in a limited space. The company introduced a folding belt conveyor, which can adjust the length as needed and flexibly adapt to different space requirements. At the same time, the system is equipped with an intelligent control device that can achieve automatic operation and remote monitoring. The successful application of the folding belt conveyor has solved the space constraints and flexibility requirements for the logistics company and improved the material transportation efficiency.

Xinxiang Dahan Machinery Equipment Co., Ltd. is a manufacturer specializing in the production of folding belt conveyors. They are dedicated to designing, manufacturing and delivering high quality, reliable folding belt conveyor solutions. The company's products are portable, space-saving and adjustable-length for temporary or mobile material handling needs in a variety of industries. Xinxiang Dahan Machinery Equipment Co., Ltd. has won the trust and wide recognition of customers through innovative design and quality service.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.