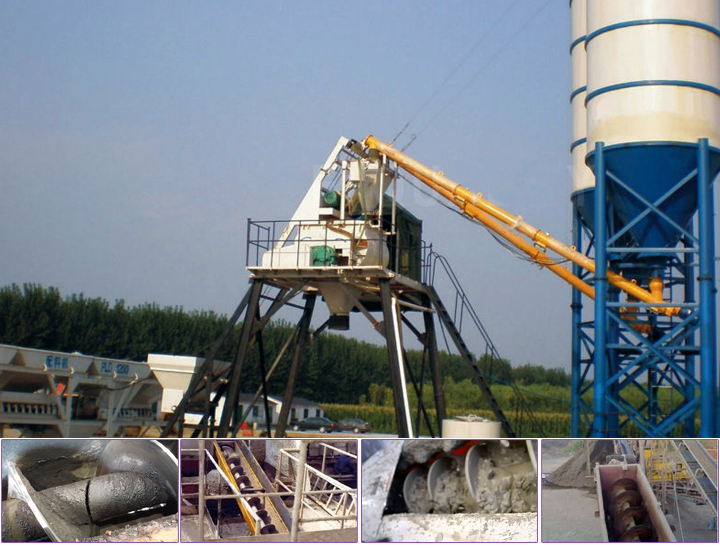

concrete screw conveyor

concrete screw conveyor wet concrete screw conveyor

wet concrete screw conveyor concrete screw conveyor parts

concrete screw conveyor parts mixing station cement screw conveyors

mixing station cement screw conveyors screw conveyors for concrete

screw conveyors for concrete

Used in the precast concrete industry to transport fresh concrete from forced mixers to moulds

![]()

![]()

![]()

Price:$800.00-$5,320.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 140-290mm

Conveying length: 30-60 meters

Delivery volume: 1.4-458 cubic meters/hour

Conveying angle: 0-60°

Motor power: 2.2-30KW

Speed: 240-310r/min

Applicable materials: Concrete, coal powder, grain, fertilizer, ash, sand, coke, etc.

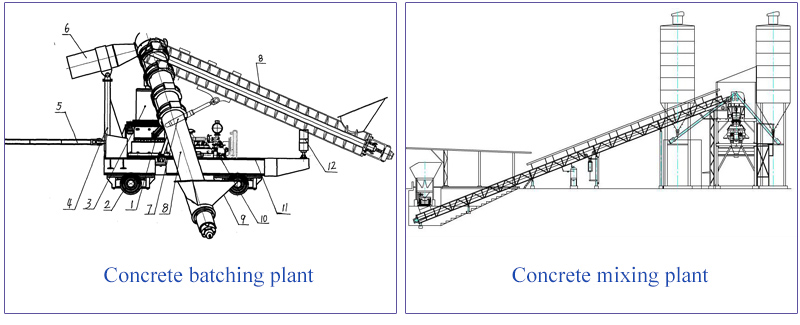

Application industry: concrete mixing station, stabilized soil mixing station

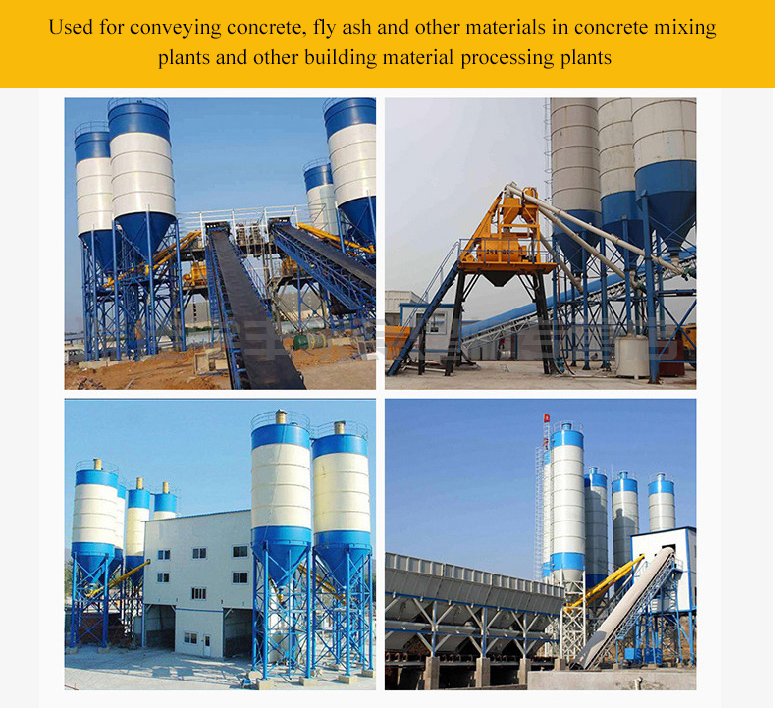

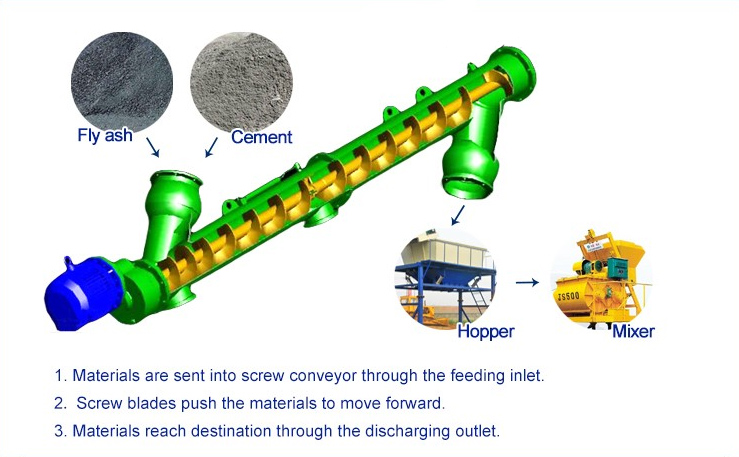

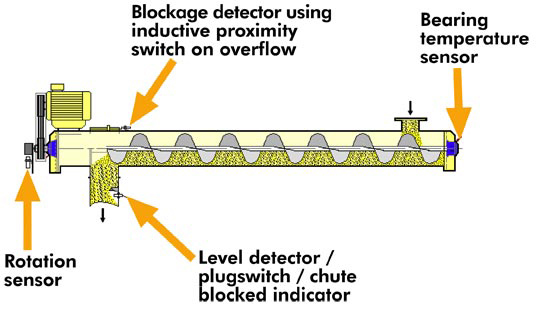

Concrete screw conveyors are specially designed for conveying cement and similar bulk solids from silos or other storage areas in concrete batching plants. Unlike other conveyors, concrete screw conveyors avoid concrete segregation and ensure uniform and continuous discharge. In order to keep concrete To homogenize and reduce the absorbed driving force, the stirring paddle in the inlet area is adjustable. By changing the angle of the paddle, the throughput rate of the concrete can be changed.

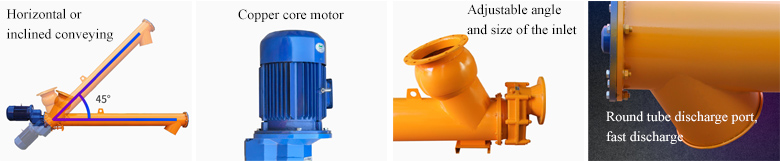

Concrete screw conveyor specifications include 140/165/219/273/325/426 and other models, the length can reach 1-20 meters, and can transport concrete, cement powder and other products horizontally or inclined (<50 degrees).

Concrete screw conveyor is mainly used in the mixing plant to transport bulk cement or fly ash from the cement silo/cement tank to the concrete mixing host, and is specially used in the precast concrete industry to transport fresh concrete from the forced mixer to the mold as a belt conveyor An alternative to screw conveyors, belt conveyors carry the risk of segregation of fresh concrete. It plays a role in coordinating and ensuring the production of concrete in the whole concrete mixing process.

convey fresh concrete

wet concrete screw conveyor for wet concrete

High conveying efficiency

There are LSY160 (shell diameter 194mm), LSY200 (shell diameter 219mm), LSY250 (shell diameter 273mm) and LSY300 screw conveyor (shell diameter 325mm), the length can be divided into 6 meters or 9 meters.

Small footprint

Because the concrete is sticky and easy to splash, the tubular screw conveyor is generally used, and the angle can reach up to 90 degrees, which saves the floor area.

Not easy to block

Double-pitch helical blades are used to reduce the degree of compression during concrete delivery, and it is not easy to block materials.

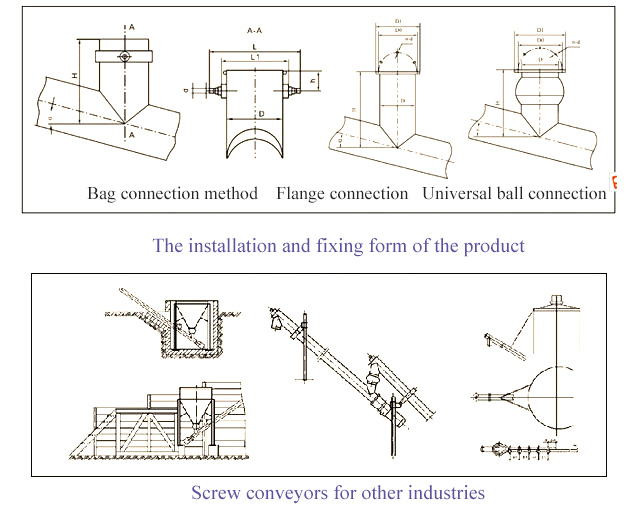

Various connection methods

The inlet and outlet have various interface connection methods such as spherical hinge, nozzle, flange, and square flange.

Anti-seepage, not easy to agglomerate

There is an anti-seepage device at the joint of the shell pipe, which can prevent the concrete from agglomerating due to the infiltration of rainwater outdoors, and then cause blockage and blockage incidents.

Sealed structure

The outer casing of the conveyor is sealed, which can effectively prevent dust from overflowing and also prevent external impurities from entering the conveyed materials.

| Model | LSY165 | LSY219 | LSY273 | LSY325 |

| Shell Diameter(mm) | 165 | 219 | 273 | 325 |

| Screw Diameter(mm) | 135 | 189 | 243 | 295 |

| Conveying Length(m) | 2-12 | 2-12 | 2-12 | 2-12 |

| Rotation Speed (r/min) | 300 | 200 | 209 | 174 |

| Working Angle (°) | 0-45 | 0-45 | 0-45 | 0-45 |

| Conveying Capacity (t/h) | 25 | 35 | 50 | 75 |

| >Motor Type | Y100L-4 | Y132M-4 | Y160M-4 | Y180M-4 |

| Motor Power (kw) | 5.5-7.5 | 5.5-11 | 7.5-15 | 7.5-18.5 |

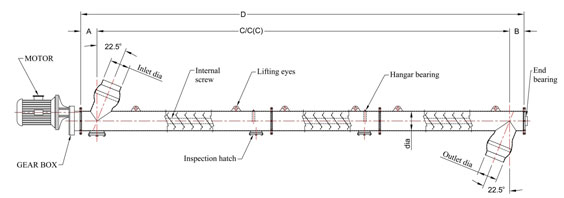

Table explains the screw dimensions with reference to the drawing shown above:

| Type | Inlet Dia | Outlet Dia | A | B | C | D |

| LSY 168 | Dia 165 | Dia 165 | 160 | 140 | As Per Customer Requirement |

D = A+C+B |

| LSY 219 | Dia 219 | Dia 219 | 180 | 160 | ||

| LSY 273 | Dia 273 | Dia 219 | 220 | 180 | ||

| LSY 323 | Dia 325 | Dia 325 | 220 | 220 |

1. The continuous spiral blade is made of high-quality imported high-strength wear-resistant steel. After forming, the pitch error is less than 5mm and the surface of the blade is smooth, which ensures the uniformity and stability of material transportation, thus ensuring the repeatability of material measurement.

2. The continuous helical blade is made of cold work hardened surface cold rolling treatment, the hardness and wear resistance are about doubled compared with ordinary blades, and the outer edge hardness can reach HB240.

3. The front and rear helical blades have two pitches of sparse and dense, which can effectively prevent the pipe from being blocked. Commonly known as "eat less, vomit faster". The high-precision manufacturing of the blade ensures that the material is filled with the tube body, and the user can judge the quality of the screw conveyor from the flattening of the canvas sleeve at the feed port of the screw conveyor.

4. The inner shaft of the screw machine is provided with an intermediate hanging bearing within a certain distance to support the rotation of the inner shaft. The intermediate hanging bearing seat is mostly made of cast steel or cast aluminum material, and the single cantilever type support body makes the blade at the front and rear joints interrupted. Smaller, the material flow is cross-sectional, so that the material flow is smooth and unobstructed.

5. The connection method between the feed inlet of the Concrete screw conveyor and the cement silo is divided into two forms: the rigid connection of the ball hinge flange and the soft connection of the hanging and waterproof canvas. The frequency of disassembly and assembly of visual equipment determines the interface form.

6. The special design of the front bearing body makes the inner shaft of the screw receive a tensile force during normal operation, and the tensile force is borne by the thrust bearing in the front bearing to prevent the reducer and the middle hanging shaft seat from being compressed, and avoid the bolt shaft being compressed by the pressure. The resulting sweep phenomenon.

1.Different types of inlet and outlet spouts

2.Additional inspection hatches

3.External supports

4.Drive unit at outlet end

5.Selection of gear ratios resulting in different feed rates

1. The installation foundation of the screw machine should be irrigated at least 20 days before the official installation of the screw machine. The foundation should be able to support the conveyor reliably and ensure that the screw machine does not sink and additional changes due to the too small foundation. It has sufficient stability during operation.

2. Before the screw machine is installed, it is necessary to clean the parts of the dirt that stick to it during transportation or when unpacking.

3. The flange surfaces of the adjacent casings should be smooth and tight, and the dislocation deviation of the joints on the inner surface of the casing should not exceed 2 mm.

4. The asbestos belt is allowed to be cushioned between the flanges of the casing to adjust the accumulated error of the length of the casing and the screw machine.

5. The gap between the outer diameter of the spiral and the casing should meet the regulations, and the gap should not be less than 50% of the nominal gap. If a larger gap is required, it should be made according to user requirements.

| Project | Screw Conveyors for Fresh Concrete | Screw conveyor for bulk handling cement powder and aggregates. |

| Customer Demand | Conveying fresh concrete from the forced mixer to the mould, avoiding concrete segregation and ensuring uniform and continuous discharge | Our client, producer of ceramic adhesive in different meshes, want to speed up and improve the transport of cement and some aggregate powders, from silos with manual unloading to transport them and deposit them in horizontal mixer of pallets, required that the equipment was fixed with adaptation of hopper container for 1 cubic meter. |

| Conveying length: 8.4 meters | Conveying height: 2 meters | |

| Delivery capacity: 10m³/h | Delivery capacity: 30m³/h |

Concrete screw conveyors provided by Dahan concrete screw conveyor manufacturers are commonly used in: powder, granular materials, widely used in: power plants, steel plants, building materials plants, cement plants, chemical plants, dust removal equipment ash conveying systems, cement manufacturers' concrete cement pipes, etc. , is often used for dust removal equipment supporting ash conveying system. We have special personnel in charge of design, drawing, modeling, processing, quality inspection, assembly, test machine, painting, delivery and other links. We have machining workshops (lathes, milling machines, boring machines, drilling machines), assembly workshops, painting workshops, warehouses, etc. . The product model is complete and the price is cheap. We can provide structural drawings and parameter quotations for free design and selection according to working conditions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.