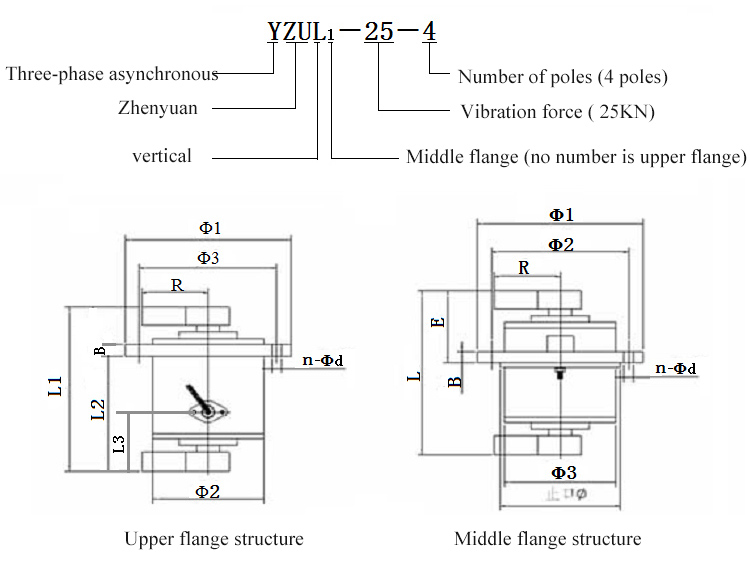

Single flange structure, is a general excitation source for all kinds of vibrating machinery

![]()

![]()

![]()

Price:$40.00-$500.00/Set

Consult now and enjoy a 10% discount

Exciting force: 1-75KN

Power: 0.12-3.7KW

Power frequency: 50Hz

Speed: 1450r/min

Protection class: IP55

Insulation class: B or F

Ambient temperature: ≤40℃

Application: It can be matched with rotary vibrating sieve, ultrasonic vibrating sieve, filter sieve and other screening machines

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Vertical vibration motor is a vibration motor specially designed for various vibrating screens. It is usually installed in a vertical position and adopts a single flange structure, making the vertical vibration motor easy to install and maintain. At the same time, the weight of the host can be greatly reduced, and the size of the host can be reduced, so that the host can handle more materials. The exciting force can be adjusted in steps within a certain range to meet various operational needs.

Vertical vibration motors are often used in processes such as screening, conveying, and compacting granular materials. It has the characteristics of compact structure, strong vibration force and stable operation. The size and frequency of vibration force can be adjusted as needed to adapt to the processing needs of different materials. This kind of motor is widely used in vibration equipment in coal, metallurgy, chemical industry, building materials and other industries, such as vibrating screens, vibrating feeders, etc. It can improve production efficiency and promote process automation and the continuous and stable operation of production lines.

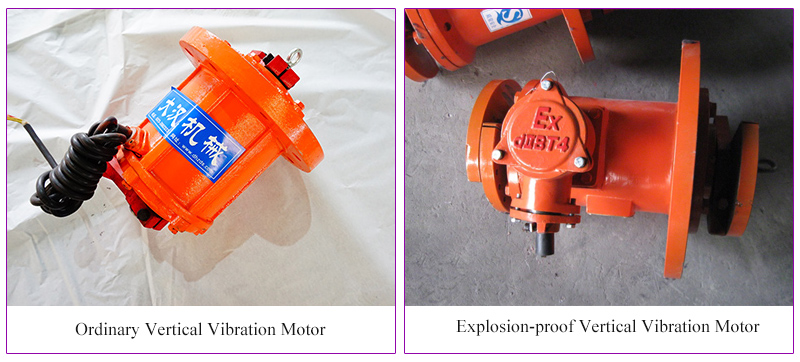

Vertical vibration motors can be divided into two main types according to their design and usage: ordinary vertical vibration motors and explosion-proof vertical vibration motors.

Ordinary Vertical Vibration Motor: For use in non-hazardous environments and not specifically designed to protect against explosions or fires. As a three-phase asynchronous vertical vibration motor, it is used as a vibration source for vibrating machines such as vibrating screens, vibrating feeders, vibrating hoppers, and vibrating tables.

Explosion-proof Vertical Vibration Motor: used to operate in hazardous environments where there is a risk of explosion or fire due to the presence of flammable gases or vapors, and can be widely used in hazardous locations with flammable and explosive gases.

| Model | Maximum Excitation Force | Speed | Power | Current | Notes |

| (KN) | (rmp) | (kw) | (A) | ||

| YZUL-3-2 | 3 | 3000 | 0.25 | 0.62 | Upper flange |

| Middle flange | |||||

| YZUL-5-2 | 5 | 3000 | 0.4 | 1.15 | Upper flange |

| Middle flange | |||||

| YZUL-8-2 | 8 | 3000 | 0.55 | 1.45 | Upper flange |

| Middle flange | |||||

| YZUL-10-2B | 10 | 3000 | 0.75 | 1.84 | Upper flange |

| Middle flange | |||||

| YZUL-10-2A | 10 | 3000 | 1.1 | 2.3 | Upper flange |

| Middle flange | |||||

| YZUL-20-2 | 20 | 3000 | 1.5 | 3.1 | Upper flange |

| Middle flange | |||||

| YZUL-3-4 | 3 | 1500 | 0.18 | 0.6 | Upper flange |

| Middle flange | |||||

| YZUL-5-4 | 4 | 1500 | 0.25 | 0.74 | Upper flange |

| Middle flange | |||||

| YZUL-8-4 | 8 | 1500 | 0.55 | 1.5 | Upper flange |

| Middle flange | |||||

| YZUL-10-4 | 10 | 1500 | 0.75 | 1.85 | Upper flange |

| Middle flange | |||||

| YZUL-15-4 | 15 | 1500 | 1.1 | 2.58 | Upper flange |

| Middle flange | |||||

| YZUL-30-4 | 30 | 1500 | 1.5 | 3.6 | Upper flange |

| Middle flange | |||||

| YZUL-50-4 | 50 | 1500 | 2.2 | 5.1 | Middle flange |

| YZUL-3-6 | 3 | 1000 | 0.25 | 1.92 | Upper flange |

| Middle flange | |||||

| YZUL-5-6 | 5 | 1000 | 0.37 | 1.22 | Upper flange |

| Middle flange | |||||

| YZUL-10-6 | 10 | 1000 | 0.75 | 2.2 | Upper flange |

| Middle flange | |||||

| YZUL-15-6 | 15 | 1000 | 1.1 | 3.1 | Upper flange |

| Middle flange | |||||

| YZUL-20-6 | 20 | 1000 | 1.5 | 4 | Upper flange |

| Middle flange | |||||

| YZUL-30-6 | 30 | 1000 | 2.2 | 5.6 | Middle flange |

Ambient temperature: no more than 40℃

Altitude: not more than 1000m

Protection class: IP55

Working voltage: 380V

Frequency: 50HZ

Connection method: Y or △

Insulation class: B or F

How it works: s1

Installation method: any direction

Strong vibration force

The vertical vibration motor can generate strong vertical vibration force to effectively promote material transportation, screening and other process operations.

Compact structure

Its design is simple and compact, easy to install, takes up little space, and is suitable for various working environments.

Stable operation

The vertical vibration motor works stably and reliably, vibrates smoothly, and can run for a long time without being prone to failure.

Flexible adjustment

The size and frequency of the vibration force can be flexibly adjusted as needed to adapt to the processing requirements of different materials.

Low noise

Compared with other vibration equipment, vertical vibration motors have lower noise when working, which is conducive to creating a comfortable working environment.

Multi-field application

Widely used in vibration equipment in coal, metallurgy, chemical industry, building materials and other industries, such as vibrating screens, vibrating feeders, etc.

| Model | L1 | L2 | B | Φ1 | Φ2 | Φ3 | II | d | L3 | R | Power(Kw) | Weight |

| YZUL-1-4 | 231 | 170 | 16 | 190 | 138 | 165 | 4 | 12 | 104 | 70 | 0.12 | 12 |

| YZUL-3-4 | 209 | 144 | 20 | 230 | 155 | 200 | 4 | 12 | 74 | 90 | 0.18 | 23 |

| YZUL-5-4 | 326 | 212 | 22 | 245 | 165 | 210 | 6 | 12 | 85 | 135 | 0.25 | 28 |

| YZUL-8-4 | 340 | 233 | 24 | 270 | 195 | 235 | 6 | 14 | 103 | 140 | 0.55 | 36 |

| YZUL-10-4 | 436 | 290 | 34 | 310 | 220 | 265 | 8 | 18 | 144 | 185 | 0.75 | 65 |

| YZUL-15-4 | 452 | 299 | 34 | 310 | 220 | 265 | 8 | 18 | 144 | 185 | 1.1 | 71 |

| YZUL-30-4 | 488 | 328 | 27 | 370 | 265 | 315 | 8 | 22 | 153 | 200 | 1.5 | 85 |

| YZUL-50-4 | 552 | 374 | 35 | 450 | 330 | 390 | 8 | 26 | 150 | 230 | 2.2 | 160 |

Vertical vibration motor is widely used in vibro sifter, ultrasonic vibrating screen, vibrating crusher, rotary vibration cleaning machine, vibrating dryer, vibrating mixer and other equipment.

Vertical vibration motors have a wide range of application scenarios in the industrial field, mainly including the following aspects:

Vibrating screening: Vertical vibration motors are often used in vibrating screening equipment and are widely used in granular material screening processes in ores, building materials, chemicals and other fields.

Vibration conveying: In the vibrating feeder, the vertical vibration motor evenly conveys the materials to the downstream equipment for continuous conveying and uniform supply of granular materials.

Vibratory compaction: In vibratory compaction equipment, vertical vibration motors are used in the production process of bricks, concrete products and other fields.

Vibration drying: It can be used in vibration drying equipment to quickly dry materials through vibration. It is suitable for drying processes in chemical industry, food processing and other fields.

Vibration processing: In some special processes, it can also be used in vibration processing equipment, such as vibrating screen powder machines, vibration mills, etc., for the processing and handling of powder particles.

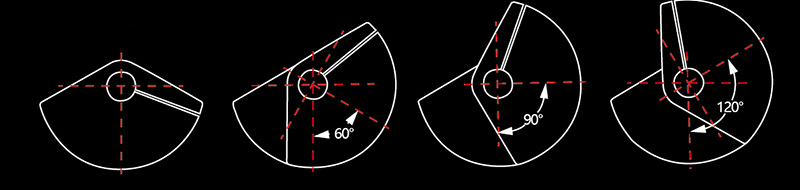

| Adjustable eccentric block angle | 0 | 60 | 90 | 120 |

| Exciting force | F | 0.86F | 0.707F | 0.5F |

1. Change the angle between the upper and lower eccentric blocks of the vertical vibration motor, which can change the movement track and residence time of the material on the screen, so that the screen machine can adapt to the required separation state of various materials, such as material distribution and production volume. Various changes such as separation efficiency and network speed should be adjusted to a better state.

2. The upper weight cannot be adjusted. Open the adjustment hole at the bottom of the base of the unit and loosen the lower weight fixing bolt. Adjust the phase angle of the upper and lower weights in the opposite direction to the discharge port according to the movement trajectory of the screening material, and tighten the fixing bolts. Then put a small amount of material on the screen surface, let the screen machine run, and check the movement track of the material on the screen surface. If the processing parameters achieve good results, stop the fixing bolts and stop adjusting (remember to tighten the fixing bolts).

3. Adjust the additional weights: Additional weights are installed on the sides of the upper and lower weights, and their function is to increase or decrease the exciting force of the screen machine.

Xinxiang Dahan Vibration Motor Manufacturer has been established for 12 years. The products mainly include: YZUL vertical vibration motor, YZU horizontal vibration motor, explosion-proof vibration motor and warehouse wall vibrator, etc., which can be widely used in linear vibrating screens and rotary vibrating screens. Straight screen, mining vibrating screen, conveying hoist, vibrating feeder, vibration table and other equipment. The vibration motor is supplied by the original factory, and each process is inspected during the product manufacturing process. Before leaving the factory, it is tested on a comprehensive test bench under full load for 8 hours to ensure various performance parameters. In addition to standard models, our manufacturer can customize various Vibration motors with different installation sizes, different voltages, special insulation levels, and protection levels (such as those used in water). The product can be shipped on the same day, and the warranty period is 6 months. We will take full responsibility for any quality problems.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.