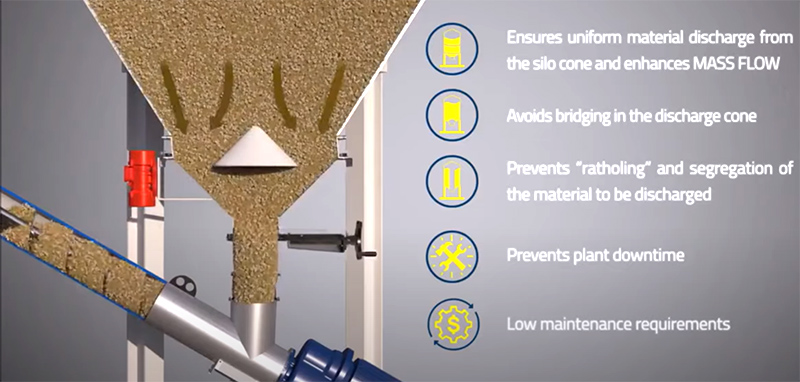

Facilitates the flow of dry bulk material from storage bins and silos, ensuring consistent discharge and preventing clogging or spillage.

![]()

![]()

Price:$400.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400-2500mm

Feed rate: 10-150t/h

Silo diameter: 8.8-5.0m

Motor power: 0.1-2*1.5kw

Voltage: 380V

Weight: 0.12-1.65t

Application: Used in various industrial applications requiring efficient handling of dry bulk materials, it facilitates the flow of dry bulk materials in various industrial applications, helping to increase efficiency, reduce waste and increase productivity.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Bin activator is also called silo bin activator, is a type of mechanical device used to promote the flow of dry bulk materials out of a storage bin or silo. The bin activator consists of a vibrating cone-shaped bottom that is attached to the bin or silo and is designed to vibrate or oscillate, causing the contents of the bin to flow through the outlet.

The bin activator is suitable for any silo, round, square, steel or concrete. Completely sealed conveying can be achieved, dust will not rise outside, and the environment will not be polluted. Adjusting the vibration force of the vibrating motor can change the feeding amount of the vibrating hopper.The vibration mechanism can be motorized or electromagnetic, depending on the type of bin activator.

The primary function of a bin activator is to promote the flow of dry bulk materials out of a storage bin or silo by breaking up any bridging, rat-holing, or buildup of material that may occur in the bin. Here are some of the specific functions of a bin activator:

1. Disrupt bridging and rat-holing: Dry bulk materials can become compacted or bridged in a storage bin, preventing the material from flowing out of the bin. A bin activator helps to disrupt these bridges and promote the flow of material.

2. Prevent buildup: When dry bulk materials are stored for extended periods of time, they can become compacted and stick to the sides of the bin, preventing the material from flowing out. A bin activator helps to prevent this buildup by vibrating the bottom of the bin, keeping the material flowing.

3. Control flow rate: A bin activator can help to control the flow rate of dry bulk materials out of a storage bin by regul

There are several common types of bin activators, each with their own design and operating principles. Here are some of the most common types:

1. Carbon steel bin activator: is a type of bin activator that is made of carbon steel, a common and durable material used in industrial applications. Carbon steel bin activators are typically used to handle dry bulk materials in a range of industries, including food processing, chemical processing, mining, and agriculture. May not be suitable for handling certain materials prone to corrosion or abrasion.

2. Stainless steel bin activator: easy to clean and disinfect, making it a hygienic choice for processing materials in industries such as food processing and pharmaceuticals, and has strong corrosion resistance, making it a suitable material for processing acidic, alkaline or corrosive materials, Commonly used in industries such as food processing, pharmaceuticals and chemicals where cleanliness and hygiene are important considerations.

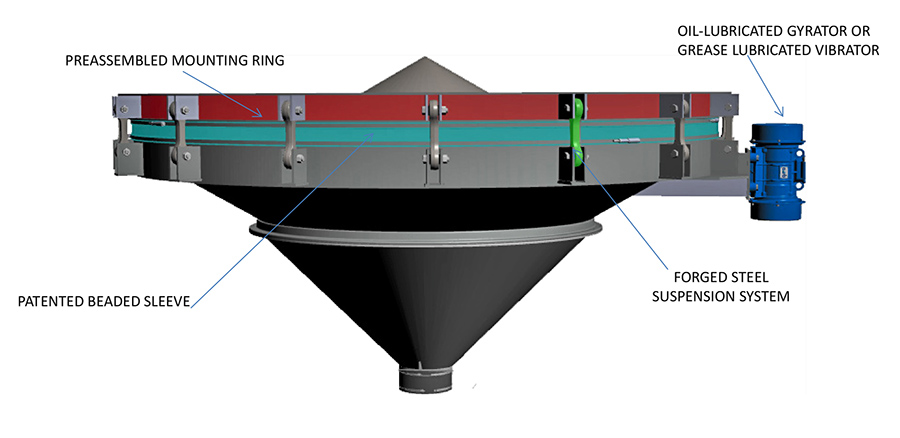

3. Motor type bin activator: r is a type of bin activator that uses an electric motor to power the vibration mechanism. The motor is typically connected to a shaft that is mounted on the bottom of the bin or silo and is used to generate a controlled vibration that promotes the flow of dry bulk materials out of the bin.

4. Electromagnetic bin activator: is a type of bin activator that uses electromagnetic vibration to promote the flow of dry bulk materials out of a storage bin or silo. The electromagnetic bin activator consists of a magnetic coil that is attached to the bin or silo and A leaf spring that is attached to a vibrating plate mounted on the bottom of the bin or silo.

5. Round bin activator: It can effectively promote the flow of dry bulk materials from round storage bins or silos, prevent blockage and ensure consistent material discharge.

6. Square bin activator: Effectively facilitates the flow of dry bulk material from square or rectangular storage bins or silos, preventing clogging and ensuring consistent material discharge, relatively easy to install, and can be customized to suit a variety of bin sizes and material types.

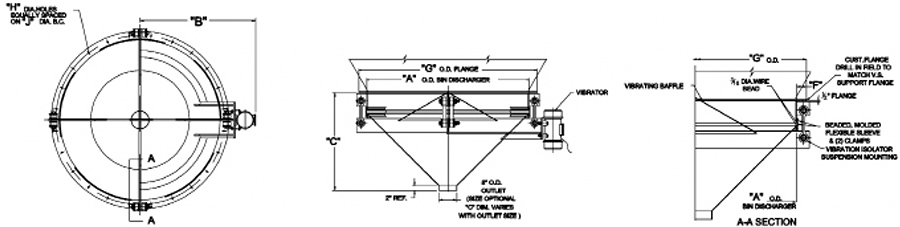

The working principle of a bin activator involves the controlled vibration of the storage bin or silo to promote the flow of dry bulk materials out of Bin activators typically consist of a vibrating plate or cone-shaped bottom that is mounted on the bottom of the bin or silo. The plate or cone is connected to a motorized vibration mechanism that generates controlled vibrations.

When the vibration mechanism is activated, the plate or cone vibrates, causing the dry bulk material to flow out of the bin. The controlled vibration frequency and amplitude ensure that the material flows out of the bin at a consistent rate, preventing blockages and ensuring consistent material discharge.

Improve material flow

Promotes material flow and prevents clogging, ensuring consistent, reliable discharge of dry bulk materials. This improves operational efficiency and reduces the risk of downtime due to material flow issues.

Improve material handling efficiency

You can increase the efficiency of your material handling process by ensuring a consistent and reliable flow of material, reducing the risk of blockages and spills.

Reduce physical labor

By facilitating the flow of dry bulk material from the storage silo, the need for manual labor to move the material is reduced.

Reduce material waste

Helps reduce material waste by ensuring that all material is drained from the storage bin or silo, reducing the amount of remaining material.

Customizable

Can be customized to fit a variety of bin sizes and shapes.

Low maintenance cost

Usually low maintenance, requiring only regular inspection and cleaning.

| Model | Vibration feeder diameter A(mm) |

Bunker diameter (m) |

Motor Power (kw) |

Flange outer diameter C(mm) |

Weight (kg) |

Excitation strength scope (kg) |

Discharge hole D(mm) |

| GZD04 | 400 | 0.4-0.8 | 0.15 | 490 | 50 | 0-150 | 120 |

| GZD06 | 600 | 0.6-1.2 | 0.2 | 710 | 100 | 0-250 | 150 |

| GZD08 | 800 | 0.8-1.6 | 0.5 | 930 | 180 | 0-500 | 200 |

| GZD10 | 1000 | 1.0-2.0 | 0.75 | 1130 | 300 | 0-1000 | 250 |

| GZD12 | 1200 | 1.2-2.4 | 1.10 | 1330 | 450 | 0-1500 | 250 |

| GZD15 | 1500 | 1.5-3.0 | 1.50 | 1660 | 650 | 0-2000 | 300 |

| GZD20 | 2000 | 2.0-4.0 | 1.50 | 2200 | 1200 | 0-3000 | 400 |

Bin activator is mainly composed of vibrating motor, vibrating hopper, activation cone, fixed hopper and other parts.

The fixed bucket is fixed at the lower part of the storage bin with bolts. The spherical surface activator is installed in the vibration bucket, and the YZD vibration motor is installed outside the bucket. Rubber ring seal.

Bin activators can be customized to fit a wide range of material handling applications, bin sizes, and material types. Here are some of the common customizations available for bin activators:

1. Size: The silo activator can be customized to fit various sized silos, from small hoppers to large silos.

2. Shape: Can be customized to fit the shape of the storage bin or silo, be it round, square or rectangular.

3. Material: Can be constructed of a variety of materials including carbon steel, stainless steel and aluminum depending on the specific material being processed and the level of durability, corrosion resistance and sanitation required.

4. Vibration frequency and amplitude: The silo bin activator can be customized to control the vibration frequency and amplitude to ensure control of material flow and prevent blockage.

5. Mounting options: Can be mounted on the bottom or side of a storage bin or silo, depending on the specific material handling application and space constraints.

6. Control options: Can be controlled manually or automatically, depending on the specific material handling application and the level of automation required.

Bin activators are commonly used in a wide range of material handling and storage applications, including:

1. Chemical processing: It can be used to facilitate the flow of powdered or granular chemicals from storage bins or silos in chemical processing plants.

2. Food processing: It can be used to facilitate the flow of food ingredients or bulk food from storage bins or silos in food processing plants.

3. Mining: Can be used to facilitate the flow of ore, minerals and other materials from storage bins or silos.

4. Pharmaceuticals: Facilitate the flow of powdered or granular pharmaceutical ingredients from storage bins or silos in pharmaceutical manufacturing plants.

5. Plastics: Can be used to facilitate the flow of plastic pellets or powders from storage bins or silos in plastic manufacturing plants.

6. Agriculture: Can be used to facilitate the flow of grain, seeds and other agricultural materials from storage bins or silos.

Xinxiang Dahan Machinery offers a range of bin activators, vibratory feeders and other material handling solutions for a variety of industries to suit a variety of material handling and storage applications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.