It can transport powdery, granular and small block materials at a large angle of 0°-60°

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 100mm-1250mm

Tilt angle: 0-60° Hopper size: 100L

Conveying length: 4-70 meters Conveying height: ≤8 meters

Conveying capacity: 244m³/h

Power Supply: 3p-380V 50-60Hz

Motor power: 7.5KW-11KW

Optional material: carbon steel, stainless steel

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Angled screw conveyor, also known as an incline screw conveyor, is a type of screw conveyor that is designed to transport materials vertically or at an incline. It consists of a rotating screw enclosed in a tube or trough that is angled to allow for the movement of materials from a lower level to a higher level.

Angled screw conveyors are commonly used in industrial applications where materials need to be transported between different levels. They can be used to move materials such as powders, granules, and other bulk solids, and are often found in industries such as food processing, chemical processing, and mining.

The inclination angle of the shaft tube screw conveyor: about 45°, the inclination angle of the shaft U-shaped screw conveyor: about 20°-30°.

The inclination angle of the shaftless tube screw conveyor: about 30°, the inclination angle of the shaftless U-shaped screw conveyor: about 20°-30°.

Reminder: For materials with poor fluidity, the inclination angle can reach 50°. However, if the material is conveyed in this way, a certain pressure must be applied to the feed inlet, and the material is squeezed into the conveying body. Moreover, the bearing at the bottom of the equipment needs to bear Huge pressure, the bearing is easily damaged.

The working principle of the inclined screw conveyor is to transport the material from the inlet to the outlet through the rotation of the screw. Its conveying process mainly depends on the friction and centrifugal force between the spiral blade and the material. When the screw blade rotates, it will push the material forward, forming a continuous conveying process.

While standard screw conveyors operate horizontally or at a slight incline (typically up to 10 degrees), angled screw conveyors can be inclined at steeper angles, typically up to 45 degrees. This allows them to perform two functions in one: conveying and elevating material.

Materials suitable for conveying at different angles:

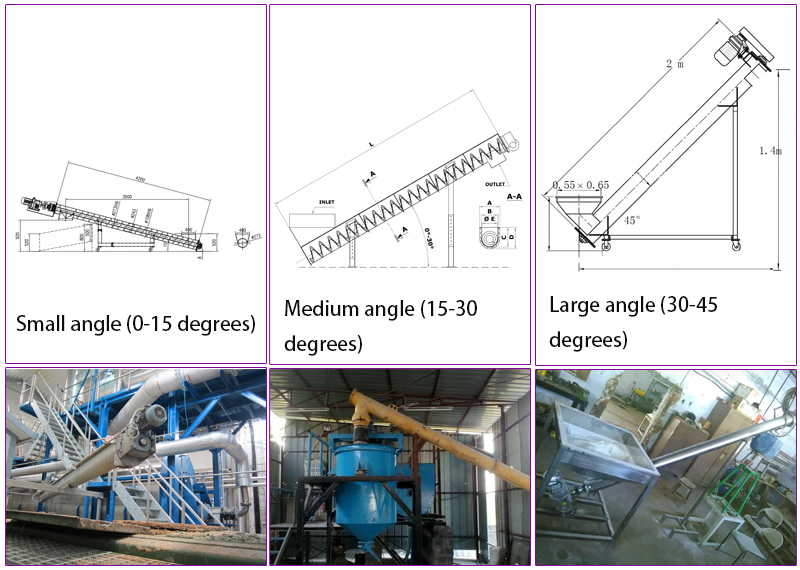

1. Small angle (0-15 degrees): suitable for various types of bulk materials, including powder, granular and small block materials.

2. Medium angle (15-30 degrees): suitable for bulk materials with good fluidity, such as powder and granular materials.

3. Large angle (30-45 degrees): suitable for bulk materials with very good fluidity, such as fine powder and fine granular materials

Angled screw conveyors are commonly used in industries such as agriculture, food processing, mining, chemical processing, and manufacturing. They are used for tasks such as feeding materials into processing equipment, transferring materials between floors, and discharging materials from storage bins or silos.

Vertical and Inclined Transport

Used to transport material vertically or at an incline, making it a versatile solution for material handling applications that involve moving material between levels.

Compact design

The compact design allows installation in tight spaces, making it ideal for space-constrained applications.

Customizable

Angled screw conveyors can be customized to meet application specific requirements. Tilt angles, lengths, diameters and materials of construction can all be customized to suit the application.

Efficient

They can move large volumes of material at controlled speeds. They are typically used in applications that require a constant and consistent flow of material.

Low maintenance

Simple design, few moving parts, easy maintenance and repair. They also require little to no lubrication, reducing the need for regular maintenance.

Versatile

A wide range of materials can be handled including powders, granules and other bulk solids. They are used in a variety of industries including food processing, chemical processing and mining.

| LS Model | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Model | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Throughput QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| Power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Throughput QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Throughput QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Throughput QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

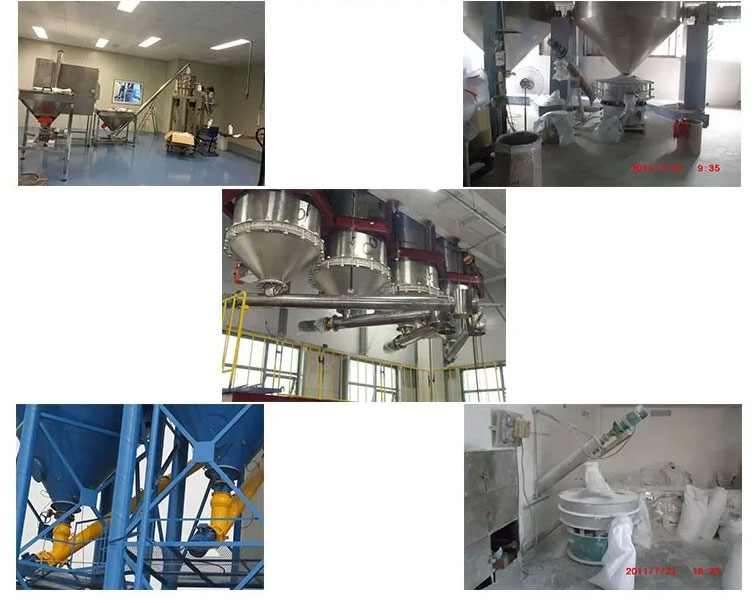

The Angled screw conveyor can be used as a stand-alone device or integrated into a larger material handling system. Here are some examples of equipment that can be used with the angled screw conveyor:

1. Hopper: It can be used to transport materials from the hopper to other processing equipment. A hopper can be located above the inclined screw conveyor and can be used to store and feed material into the conveyor.

2. Mixer: Angled screw conveyor can be used to transport materials to the mixer for mixing or blending. Screw conveyors can be used to move materials to the mixer at a controlled rate, ensuring the materials are properly mixed.

3. Bag unloading station: It can be used to transport materials from the bag unloading station to other processing equipment. Screw conveyors can be used to move material from the bag dump station to the equipment at a controlled rate, preventing over- or under-feeding.

4. Silo: It can be used to transport materials from the silo to other processing equipment. Screw conveyors can be used to move material from the silo to the equipment at a controlled rate, ensuring that the equipment is not overloaded.

5. Bucket elevator: It can be used in combination with the bucket elevator to transport materials between different levels of the processing plant. The screw conveyor can be used to convey the material to the bucket elevator, which then conveys the material to the next floor of the factory building.

During the production process, a powder raw material needs to be conveyed from underground to the production line above. The manufacturer chose our company's inclined screw conveyor. The conveyor is designed with two bins according to the process requirements, which can be loaded with two different materials respectively, and the precise control is realized through the interlock control system. The conveyor works stably and has high efficiency, which provides a reliable guarantee for the transportation of the production line.

1. Adaptability of the inclination angle of the conveyed material: The inclination angle range of the material that the angled screw conveyor can convey is generally 15° to 45°, but the specific value depends on factors such as the characteristics of the material, the screw diameter, and the rotation speed.

For materials with an inclination angle close to or exceeding the maximum allowable value, necessary measures should be taken, such as increasing the screw diameter, increasing the rotation speed, and using anti-backflow devices, to ensure the smooth conveying of the material.

2. Calculation of conveying capacity: The larger the inclination angle, the smaller the conveying capacity, because the material is more likely to slide down at a larger inclination angle.

3. Power and torque: The larger the inclination angle, the greater the power and torque, because greater gravity resistance needs to be overcome.

4. Structural design considerations: The structural design of the angled screw conveyor should consider the impact of the inclination angle on the structure, and take necessary measures, such as strengthening support and adding anti-backflow devices, to ensure the strength and stability of the structure.

5. Anti-backflow measures: During the conveying process of the angled screw conveyor, the material is prone to backflow in the gap between the spiral and the groove, causing blockage or reduced efficiency. Necessary anti-backflow measures should be taken, such as reducing the gap between the spiral and the groove, using anti-backflow devices, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.