Belt conveyor systems come in a variety of configurations to suit different material handling needs.

Most basic and versatile type.

Utilizes a flat, continuous belt to transport a wide range of materials, from boxes and packages to bulk solids.

Suitable for horizontal or slightly inclined conveying.

Designed to transport materials at an incline, often used to elevate materials to different levels.

May require chevron cleats or special belt surfaces to prevent material from slipping during incline conveying.

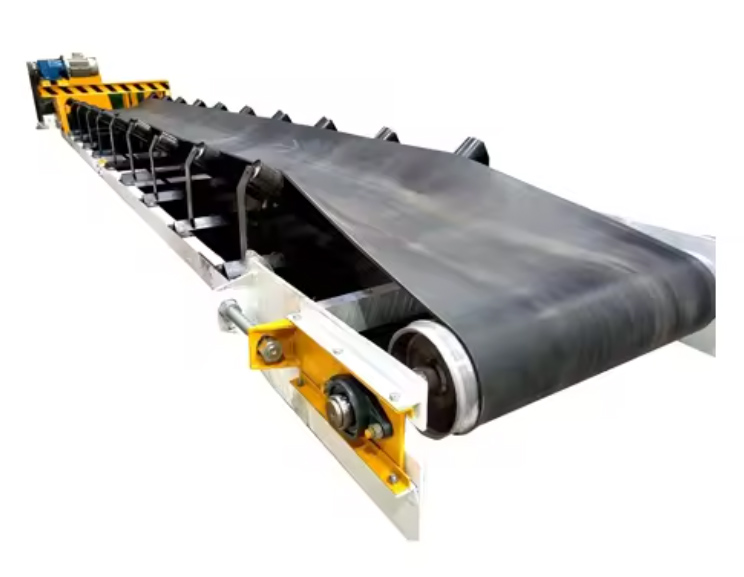

Employs a belt that forms a trough-like shape, better containing loose bulk materials like sand, gravel, or grain.

The trough shape allows for steeper inclines compared to flat belts.

Incorporates rollers along the length of the conveyor bed to support the belt and reduce friction.

Offers smoother operation and is suitable for heavier loads or materials that might damage a flat belt.

Utilizes a solid, low-friction surface as the bed for the belt to slide on.

More economical than roller beds but may not be suitable for very heavy loads.

Features cleats attached to the belt surface to provide better grip and prevent material from sliding backward on inclined conveyors.

Cleats come in various shapes and sizes depending on the material being conveyed and the incline angle.

Constructed from interlocking plastic modules that can be easily assembled and reconfigured.

Offers flexibility for changing layouts or handling delicate materials that require a smooth surface.

Designed for temporary use or easy relocation.

Often lightweight and can be folded or collapsed for storage.

Used to create stockpiles of bulk materials by stacking them at a discharge point.

The conveyor boom can be raised or lowered to adjust the stacking height.

Combines a conveyor belt with a vibration mechanism to facilitate material movement.

Useful for preventing material buildup on the belt or assisting with material flow in applications like feeding hoppers or sifting.

Choosing the right belt conveyor system depends on factors like the material being handled, capacity requirements, conveying distance, inclination angle, and operating environment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.