Grain sieves is a special instrument used to detect the impurity content and bran powder content of grain and oil crops, which is convenient for pricing various grains. This article will explain its purpose and application in detail.

Seed impurity removal is an important prerequisite for high crop yields. In the past, due to the limitations of the development of science and technology, most experimenters used manual visual inspection, water selection, winnowing, etc. to remove impurities. Not only the labor cost is high, the time-consuming and labor-intensive efficiency is low, but also the error is huge, which seriously affects the human body. affect the accuracy of the test results. Today, the application of grain sieves in seed removal is significantly more efficient than traditional methods of removal of impurities, and has the most efficient design features. The investment and application of this instrument can not only reduce labor costs, improve inspection efficiency, but also ensure The accuracy of the test results will promote the development of the grain and oil industry. It is widely used in grain purchase, storage, processing, storage and transportation, scientific research, health, foreign trade and other related departments.

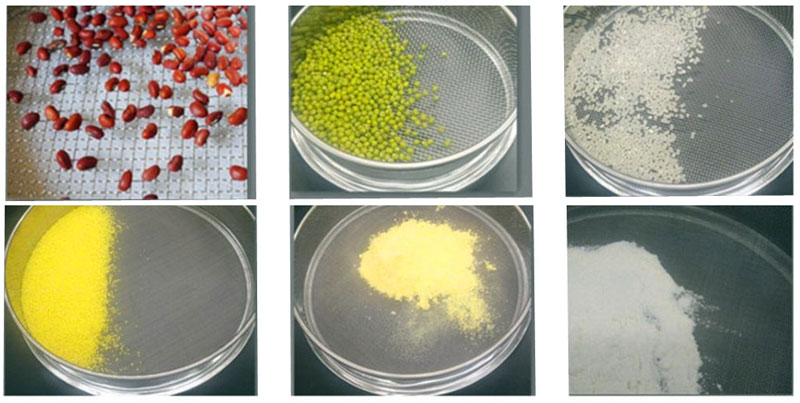

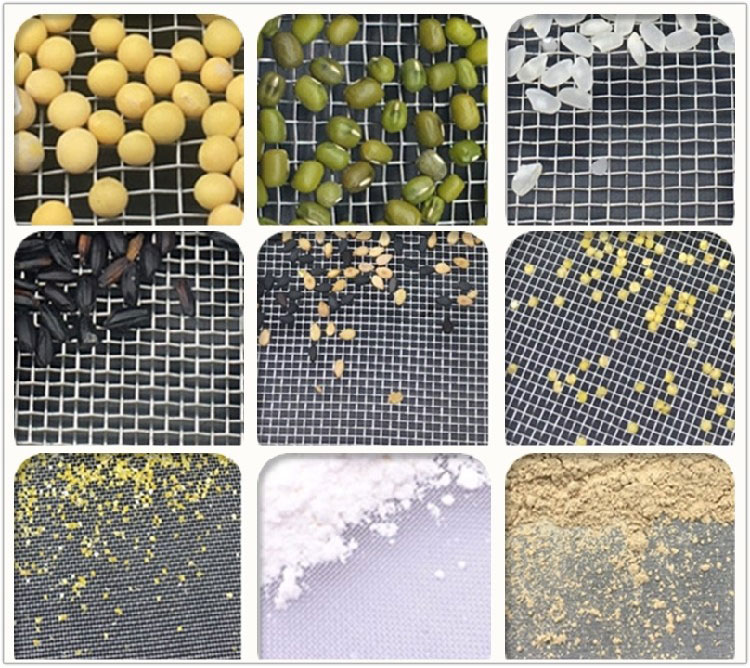

Take the screening of rice as an example. For rice, bran powder, minerals, barnyard grains with hulls, and rice grains are specified; for millet, only minerals and grains are specified; for sorghum rice, minerals and sorghum hulls are specified; Minerals, millet, millet, etc. Workers often pass through grain sifters to determine the quality of the rice. It uses the working principle of separating materials with different width, thickness or shape. The main functions are reflected in the following three points:

1. Separation according to different grain widths: the circular sieve holes are mainly separated according to the different widths of materials.

2. Separation according to the thickness of the grains: the rectangular sieve holes are separated according to the thickness of the materials.

3. Separation according to the shape of the grain: the triangular sieve is mainly separated according to the shape of the material.

In addition to rice that will be screened using grain sieves, other grains and feeds are usually tested for seed testing during grain purchase or storage. This is also a guarantee for the safety of both parties. After sieving, the impurity rate and impurity content in the grain can be calculated from the results, which provides a reliable basis for the quality classification of seeds. The grain filter developed and produced by Top Yunnong adopts a desktop structure. The rod mechanism is used for plane rotation. In the electronic control part, a single-chip microcomputer is used to control the forward and reverse rotation, which greatly improves the accuracy. It is widely used in the screening and determination of grain, oil, seeds and feed. It is an "important equipment" for agricultural breeding experts.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.