Sand sieving machine is a tool used to separate sand grains of different sizes from each other. The machine is commonly used on construction sites to sieve sand for concrete mixing, plastering and other construction activities, this article will give you a detailed introduction to the sand sieving machine.

The role of the sand sieving machine is to separate sand particles of different sizes from each other, ensuring that the sand used in various applications is of consistent size and quality. This is important in many construction and industrial applications that require sand of a specific size or quality.

1. On construction sites, it can be used to screen sand for concrete mixing, plastering and other construction activities. The machine ensures that the sand used is of a consistent size, which is important to ensure the strength and durability of the resulting concrete structures.

2. In the foundry industry, it can be used to separate sand from the mold. This machine ensures that the sand used in the casting process is of a specific size and quality, which is very important in ensuring the quality and consistency of the final casting.

3. In the field of agriculture, it is used to separate soil from rocks and other debris. The machine helps to ensure that the soil used is of consistent quality, which is important for ensuring the health and productivity of your crops.

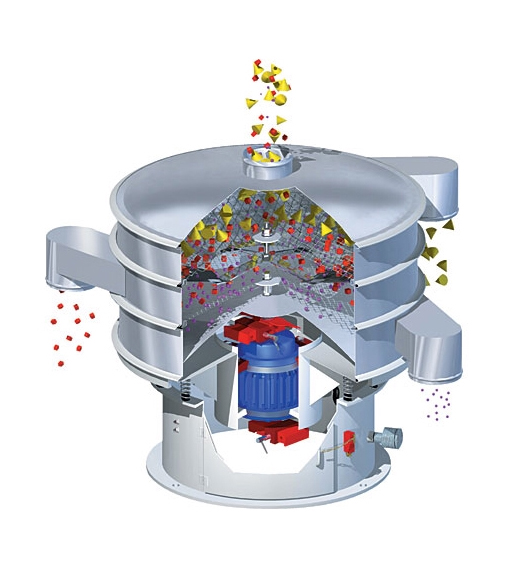

The process of sieving sand involves passing a mixture of sand grains of different sizes through a screen or screen, which allows smaller particles to pass through while retaining larger particles on top of the screen or screen. The following are the general steps involved in the sand screening process:

1. Prepare sand: The sand used for screening is usually collected and prepared in advance. Remove any debris or large particles from the sand to ensure the sand is of a consistent quality.

2. Set up the sieving machine: The sieving machine is set up with the appropriate mesh or sieve for the specific application. The machine is usually mounted at an angle to promote the flow of sand through the screen or screen.

3. Sand pouring: pour the prepared sand on the screen or above the screen, and start the machine.

4. Start the machine: apply a vibrating motion to the machine frame.

5. Collect the separated sand: the separated sand is collected in the screen or in the tray or silo below the screen. The sand is sorted by size, with the smaller particles falling through the screen or screen first, and the larger particles remaining on top.

6. Repeat the process: Repeat the process until the desired amount of sand of a specific size is obtained.

There are many types of sand sieving machines to choose from, from manual hand-held units to motorized machines that can sift large quantities of sand quickly and efficiently. Here are some common sand screen machine types:

1. Handheld Screeners: These are small, portable screeners that are manually operated. They are typically used in small-scale applications and are ideal for sieving sand samples in a laboratory setting.

2. Tumbling sand sieving machine: These machines are electric powered and designed to screen large quantities of sand. They are commonly used on construction sites to screen out sand used for concrete mixing, plastering and other construction activities.

3. Vibrating screen sand sieving machine: These machines use vibration to screen sand particles of different sizes. They are commonly used in industries such as the foundry industry, where the sand is separated from the casting mold.

4. Drum sand sieving machine: These machines are cylindrical and designed to screen sand by rotating the drum. They are commonly used in industries such as agriculture, where soil is separated from rocks and other debris.

In general, the type of sand screen used depends on the specific application and the amount of sand to be screened.

The price of a sand sieving machine can vary depending on various factors such as the make, model, capacity, and features of the machine. In general, handheld screeners are the least expensive, while electric machines with advanced features can be more expensive. Handheld sieving machines can be found for as little as $10 to $20, while tumbling sand sieving machines: can range from $200 to $2,000, depending on capacity and features. A vibrating screen sand sieving machine can range in price from $1,000 to $10,000, depending on capacity and features, while a rolling drum sand sieving machine can cost between $2,000 and $10,000. It should be noted that these are rough estimates, and the actual price of sand sieving machine may vary according to the specific requirements of customers. It is recommended to do some research and compare prices of different manufacturers and suppliers before making a purchasing decision.

Sand sieving machines are must-have tools for construction projects that require sand of consistent size. They are also commonly used in the foundry industry to separate sand from molds and in the agricultural industry to separate soil from rock and other debris.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.