Plastic vibro sifter is also called polypropylene vibro sifter, mainly to solve the problem of chemical reaction caused by contact between materials and metal. The plastic vibro sifter device is completely made of non-metallic materials, which completely eliminates the chemical reaction of some special materials in contact with the metal sieve body, which will corrode the sieve machine.

It is composed of a feed port, a dust cover, a discharge port, a screen, a beam ring, a counterweight, an upper weight, a vibrating body, a motor, a spring, a base, and a lower weight.

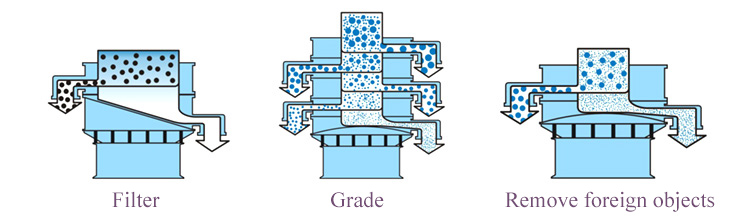

1.Sieving

The difference between plastic vibro sifter and stainless steel vibro sifter is that it has better corrosion resistance than stainless steel vibro sifter. Sieving is to divide solid particles into groups of equal size. A single series of screening machines can be equipped with 1 to 5 layers of screens, which can accurately and continuously sort 2 to 6 particle segments at the same time; the classification accuracy is more than 95%.

2.Impurity removal

The high-precision screen can quickly remove large or small particles with a low percentage during the processing of high-flow materials. Most of them are used in single layer. The advanced design of the series of vibro sifter filters can remove impurities with high efficiency and high quality; the accuracy can reach more than 98%.

3.Filter

Vibro sifter can quickly remove insoluble large particles in various slurries. Most of them are used in single layer, and the series of specially designed screening filters can filter up to 20 tons per hour.

Prevent material corrosion-the most significant feature of the plastic vibro sifter is that it can resist the corrosion of the material to the screen machine.

Anti-clogging of the mesh-The plastic vibro sifter function and the automatic cleaning and blocking device designed by our company minimize the probability of blocking the network.

High-efficiency and precise screening-all incoming materials are automatically discharged, and there is no stock in the machine. Compared with the same screen surface plastic vibro sifter, the vibro sifter has a larger capacity than other types of sieves. Single-layer or multi-layer sorting--Each plastic vibro sifter can choose 1 to 3 layers of screens, which can carry out 2 to 4 grades of sorting or filtering at the same time.

The plastic vibro sifter uses a vertical motor as the excitation source. When the sieve machine is started, the eccentric weights installed at the upper and lower ends of the motor convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion. The movement is transmitted to the screen surface, so that the materials smaller than the screen surface aperture fall to the lower layer through the screen holes and become under-the-screen objects. The materials larger than the screen surface aperture are discharged from the discharge port after continuous jumping motion, and the weight of the upper and lower ends is adjusted. The phase angle of the hammer can change the trajectory of the material on the screen surface, so as to achieve the purpose of screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.