Ultrasonic vibro sifter is to convert 220V, 50Hz electric energy into 38KHz high frequency electric energy, input the ultrasonic transducer, and turn it into 38KHz mechanical vibration, so as to achieve the purpose of sieving and cleaning the net, making the ultra-fine powder sieving easy. . The system introduces a low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) on the screen on the basis of a traditional vibrating screen to improve the screening performance of ultra-fine powder. Especially suitable for users who engage in value-added fine powder.

1. Solve the blockage: the screen frame is operated in three dimensions under the action of the vibrating motor, and at the same time is subjected to a high-frequency and low-amplitude ultrasonic vibration wave from the transducer, so that the material is suspended on the screen surface at a low altitude, making the contact with the fine material of the screen faster Through the screen, the penetration rate is increased, thereby effectively solving the problem of material blockage;

2. Secondary crushing: Some materials will cause problems for the troupe when they are exposed to moisture or friction to generate static electricity. Under the action of ultrasonic waves, the aggregated materials can be crushed twice, thereby increasing the output;

3. Light specific gravity screening: ordinary vibrating screens are prone to material escape and the screening accuracy cannot be reached when screening light specific gravity materials. Ultrasonic vibro sifter reduces the vibration height of the material under the action of ultrasound, and maintains the material and the screen surface. Contact, reduce the phenomenon of material emptying, can effectively improve the accuracy of screening and reduce the problem of dust escape.

1. Reduce or not produce net cleaning time.

2. No pollution to the powder caused by auxiliary materials such as bouncing balls.

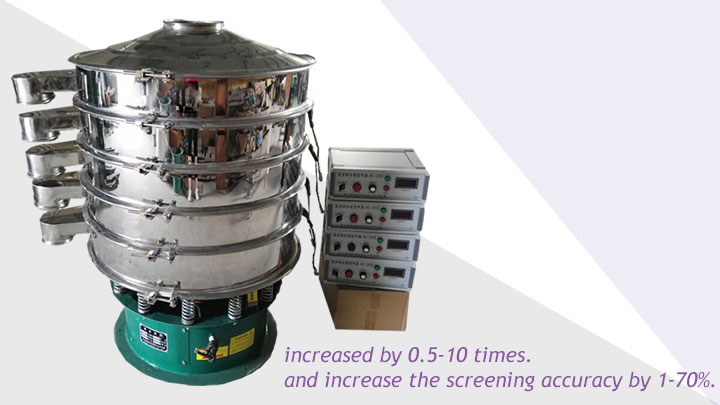

3. Maintain the mesh size, stabilize the screening accuracy, and increase the screening accuracy by 1-70%.

4. Decompose the adherent substances, reduce the sieve, and the output can be increased by 0.5-10 times. .

5. Reduce the number of screenings.

The high-frequency electricity generated by the Ultrasonic vibro sifter's power supply is converted into a high-frequency sinusoidal longitudinal oscillatory wave by the transducer. These oscillatory waves are transmitted to the resonator to resonate the resonator, and then the vibration is uniformly transmitted to the screen surface by the resonator. . The material on the screen is subjected to low-frequency three-dimensional vibration and superimposed on ultrasonic vibration, which can prevent the mesh from

Address:China,Yanjin county forest park gate to the west 1000 meters north road.