Vertical screw conveyor is also called vertical screw conveyor, which can lift various bulk materials in the vertical direction, use the motor to drive the screw rotation through the reducer, and transport the materials to the predetermined position through the rotation. This article will explain the vertical screw conveyor in detail for you.

The material rotates with the screw at a high speed, the conveyed material is added from the feed port of the horizontal part, fed into the conveyor and the vertical part through the rotating horizontal feed screw, and then the material is pushed up to the discharge port. The discharge port is fed by the vertical screw, The material rotates with the screw at a high speed, and the conveyed material is added from the feed port of the horizontal part, enters the conveyor through the rotating horizontal feed screw, and then pushes the material to the discharge port with the vertical screw for discharge.

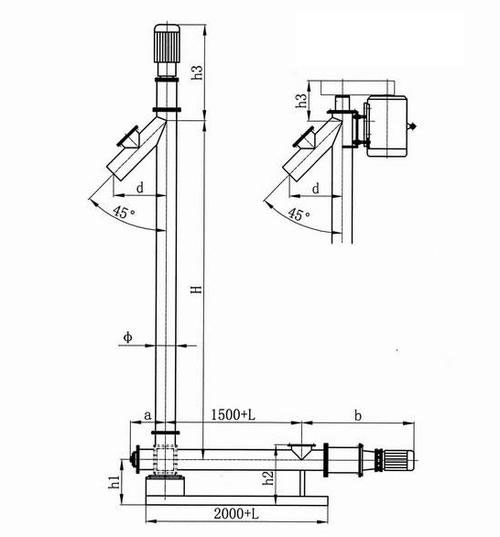

Vertical screw conveyor consists of horizontal screw conveying and vertical screw conveying.

The feeding of the vertical screw conveyor must maintain the necessary feeding force. When the feed height difference is small, the vertical screw conveyor is equipped with a horizontal feed screw. Generally, the horizontal feeding screw and the vertical conveying screw are integrated. The diameter of the horizontal feeding screw is the same as that of the vertical feeding screw, and the rotation speed of the horizontal feeding screw is lower than that of the vertical feeding screw.

1. It is used to transport powder or granular materials from low to high, without using internal bearings to lift bulk materials up to 8 meters.

2. Completely enclosed in the pipeline, no material will be lost, and dustproof requirements are met.

3. Most of the materials are sent to the vertical conveyor through the linear or offset horizontal feed conveyor, which makes the conveying of materials smoother and is not easy to block and return.

4. Smallest footprint among all vertical conveying systems.

Vertical screw conveyors are used where space is limited but material must be lifted. It is very effective for conveying most powdery and granular materials, but due to the influence of the lifting height, some materials will inevitably slide down, which makes them have requirements on the state of the materials to be conveyed. Generally speaking, vertical screw conveyors are suitable for conveying the following materials :

1. Granules, powders

2. Non-viscous dry materials with bulk density ≤ 1.3t/m

3. Density from 1010PCF to 50PCF (medium density)

4. Dry to materials with low moisture content

5. Non-perishable

Specific materials: grain, feed, cement, chemical raw materials, flour, sugar, lime, etc.

The product can be lifted to the height required to fill the hopper or silo, and the vertical conveying height can be up to 8 meters

Address:China,Yanjin county forest park gate to the west 1000 meters north road.