The whole body of the medicinal vibro sifter is made of SUS304 stainless steel, which is in full compliance with food and pharmaceutical standards to minimize the pollution of materials.

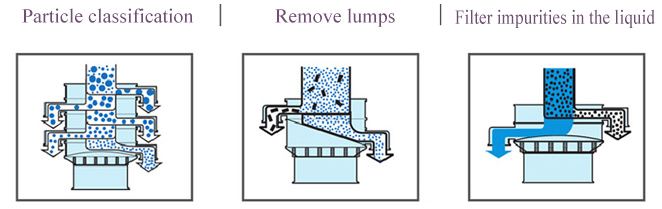

1. Particle classification

The powder and particles can be accurately divided into 2-5 grades, with a classification accuracy of more than 95%.

2. Remove lumps

Filter out the agglomerated or unqualified materials in the materials, and the accuracy can reach more than 98%.

3. Filter impurities in the liquid

Removal of particles/foreign objects in liquid materials, with a filtration capacity of up to 5 tons per hour.

Vibro sifter generally screens powder and flake materials for the pharmaceutical industry. During the screening process, the materials can be classified according to the different particle sizes by adding multiple outlets, such as the production of pills. The initial raw materials of the pills are based on the mesh size. The same powdery material is condensed, and the size of the powder will affect the coagulation. The vibro sifter can evenly distribute the boring of each layer with different particle sizes. After the pill is successfully made, the classification of the pill also needs to be processed by the vibro sifter.

Precautions:

1. The connection part between the screen frame and the part where the screen frame and the grid frame need to be replaced by the rubber apron is mainly to prevent the material from entering the silicone apron during the screening process. The use of silicone material can be Avoid physical or chemical changes in materials.

2. Because the material is used in the pharmaceutical industry, during the production of vibro sifter, it is necessary to wipe all corners of the sieve with alcohol every time it stops.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.