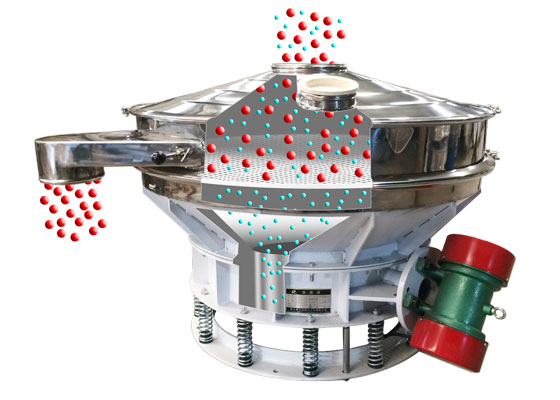

Direct discharge sifter is a kind of rough sieving machine for sieving powder and granules. This article will explain the product advantages of direct discharge sifter in detail.

1. Fast discharge and large output

The discharge port is designed at the bottom of the sieve, which is beneficial to increase the discharge particle size and discharge volume. The capacity is large, which is 2-5 times that of the ordinary rotary vibrating screen.

2. No pollution

It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution to materials.

3. No dust

Good air tightness, no dust scattering, can be directly used with dust-free feeding station to realize negative pressure and dust-free operation.

4. Easy to adjust

There are two arrangements of single motor and double motor, which can be adjusted arbitrarily from 30 to 60 degrees to increase the running track of materials.

5. Small footprint

The motor is designed outside the equipment, reducing the height of the equipment and effectively using the space; the equipment is easy to operate, and the large obtuse angle is easy to clean.

The direct discharge sifter enables simple safety screening and precise grading of powders or granules for: paints, veterinary drugs, flour, fertilizer granules, pebbles, Oreo powder, lithium carbonate, lithium hydroxide, dyes, food additives, sulfur Ammonium, lime powder, sand, coal powder, plastic additives, condiments, sodium sulfate, metal powder, chemical raw materials, starch, silicon carbide, zinc oxide powder, puffed soybeans, feed additives, calcium powder, soda ash.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.