Molybdenum powder is a rare metal powder, and molybdenum powder is widely used in industries. Small-size molybdenum powder particles are easy to form enrichment and bridging phenomena, which is what we often say that molybdenum powder has "adhesiveness". When this type of molybdenum powder is sieved through vibro sifter, it is easy to form a dense adhesion state and block vibration. The sieve hole reduces the penetration rate. Agglomeration means that molybdenum powder particles form larger particles through surface tension or solid bond bridging, that is, agglomerates. The particle appearance of agglomerated molybdenum powder is irregular, which seriously affects the penetration rate and product quality of vibro sifter.

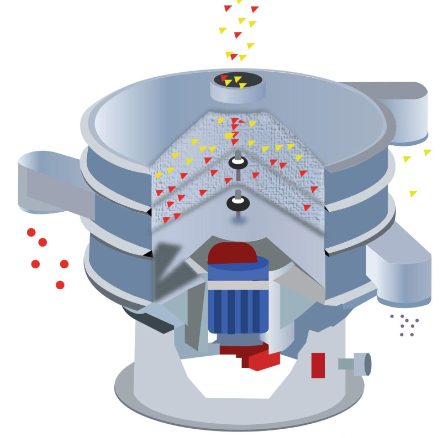

Vibro Sifter for Sieving Molybdenum powder separates molybdenum powder into fine molybdenum powder particles with high precision and rapid screening capabilities. Unwanted impurities in the material can also be removed during the screening process. The excitation force generated by the vibration motor causes the screen to vibrate reciprocally, thereby realizing the screening of molybdenum powder. The screen adopts a special design, which can effectively solve the problem of molybdenum powder agglomeration and improve screening efficiency. In addition, the ultrasonic vibrating screen introduces low-amplitude, high-frequency ultrasonic vibration waves to the screen to further decompose adherents and break up agglomerated particles, significantly improving screening accuracy and efficiency.

In view of the above situation, the selection of vibro sifter suitable for screening molybdenum powder should start from the following aspects:

1. The vibro sifter can prompt the molybdenum powder particles to move quickly along the screen surface to improve production efficiency.

2. The vibro sifter can ensure that the fine particles of molybdenum powder passing through the sieve have sufficient contact opportunities with the sieve surface.

3. The vibro sifter can prompt the molybdenum powder to turn strongly and help it to penetrate.

4. The vibro sifter machine can effectively prevent the agglomeration of coarse molybdenum powder particles and help fine molybdenum powder pass through.

| Parameter | Specification |

| Model | Customizable (e.g., VS-600, VS-800, VS-1000) |

| Screen Diameter | 600 mm, 800 mm, 1000 mm (or custom sizes) |

| Number of Screen Decks | 1 to 5 decks |

| Mesh Size | 20 µm to 500 µm (customizable) |

| Capacity | 100 kg/h to 2000 kg/h (depending on model) |

| Vibration Motor Power | 0.25 kW to 1.5 kW |

| Vibration Frequency | 1500 to 3000 RPM (adjustable) |

| Amplitude | 2 mm to 5 mm (adjustable) |

| Material of Construction | Stainless steel (304 or 316L) |

The currently applicable vibro sifter for sieving molybdenum powder can meet the normal operation of the screening process, but it is inevitable that materials will be mixed and unevenly fed during the operation, which will affect the screening efficiency of the molybdenum powder. In addition, the flying of materials easily leads to environmental pollution and reduced recovery rate. In the screening process of small particle size molybdenum powder or large mesh screen, there will be too many times of cleaning, adhesion and blockage, etc., which increases labor intensity at the same time. Effectively improve the situation of material flying.

Therefore, in order to improve the screening efficiency and product quality of vibro sifter, and to minimize the clogging of the screen, the manufacturer of vibro sifter recommends the use of ultrasonic vibro sifter to screen molybdenum powder.

Ultrasonic vibro sifter can not only improve the accuracy and efficiency of molybdenum powder screening, reduce the cleaning time, but also eliminates the need to install a cleaning device, reducing the pollution of the powder by auxiliary cleaning devices such as bouncing balls. The ultrasonic vibrating screen passes through the 18Khz attached to the screen. The ultra-high frequency mechanical vibration force is as high as 36,000 times per second, which can effectively decompose adhering substances, break up agglomerated molybdenum powder, reduce the content on the sieve, and can maintain the size of the sieve, prolong the service life of the sieve, and stabilize the sieve Sub-accuracy.

Experiments have proved that the molybdenum powder is sieved with an ultrasonic vibro sifter equipped with a 280-mesh screen to meet international export standards, and the average yield can reach 86.5%. And after being judged by a professional tap density tester, after screening, the sum of the ratio of the contents on the vibrating screen is about 1‰ on average, which is much higher than the qualified requirement of less than 5‰ for the contents on the sieve. This means that the existence of ultrasonic vibro sifter greatly reduces the labor intensity of employees, reduces environmental pollution, and improves screening efficiency and product quality.

If you need to inquire about the machine, please contact and learn more about it.

Coarse screening of molybdenum powder: remove large particles or agglomerates in molybdenum powder. Large processing capacity, suitable for preliminary screening.

Fine screening of molybdenum powder: High-precision classification of molybdenum powder to ensure that the particle size meets the requirements. It is suitable for screening ultra-fine molybdenum powder (such as the particle size is less than 400 mesh). It has high screening accuracy and is not easy to block the network.

Removal of impurities from molybdenum powder: remove foreign matter or impurities in molybdenum powder. The multi-layer screen design effectively separates impurities.

Particle size control of molybdenum powder: Ensure that the particle size distribution of molybdenum powder meets the requirements of specific applications. It can precisely control the particle size range of molybdenum powder and is suitable for high-end applications (such as the electronics industry).

| Features | Ultrasonic vibrating screen | Rotary vibrating screen |

| Working principle | Ultrasonic generator generates high-frequency vibration to make the screen produce micro-vibration to prevent blocking | Ultrasonic motor generates three-dimensional rotational vibration to make the material move on the screen surface |

| Screening efficiency | High, suitable for fine screening, especially for ultrafine powder | High, suitable for general powder screening |

| Applicable particle size range | Suitable for ultrafine powder (usually less than 400 mesh) | Suitable for coarse powder (usually greater than 400 mesh) |

| Blocking situation | Not easy to block the screen, ultrasonic vibration effectively prevents material adhesion | Easier to block the screen, especially for sticky materials |

| Energy consumption | High, requires additional ultrasonic generator power supply | Low, only motor power supply |

| Maintenance cost | High, ultrasonic generator needs regular maintenance | Low, simple maintenance |

| Equipment price | High | Low |

| Applicable scenarios | High-precision screening, such as medicine, chemical, food and other industries | General screening, such as metallurgy, building materials and other industries |

| Noise level | Low | High |

| Screening accuracy | High | Medium |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.