Cobalt powder is a metal powder. In the field of cemented carbide and diamond tools, ultrafine cobalt powder is widely used as a binder. The application range of cobalt powder is more and more extensive, and the consumption of cobalt powder is also rapidly increasing. This puts more and more stringent requirements on the performance of the raw cobalt powder. The preparation process of the cobalt powder and the morphology, particle size and purity of the cobalt powder directly affect the quality of subsequent products. Vibro sifter must undertake the precise screening of fine cobalt powder. Share responsibility.

The common mesh number of cobalt powder is 40-325 mesh. However, because cobalt powder has the characteristics of acid solubility, magnetism, easy agglomeration, strong adsorption, high precision, high stability, etc., it is a difficult problem to screen cobalt powder. Ordinary vibrating screens cannot achieve the screening target at all. High-frequency screening equipment that absorbs precipitation and agglomerates can achieve efficient screening of cobalt powder. After long-term experimental research and customer test machine feedback, Jinhe Machinery recommends the use of ultrasonic vibro sifter and centrifugal sifter for customers to choose from for cobalt powder screening.

A. Ultrasonic vibro sifter

1. The sonic vibro sifter is a screening equipment that adds an ultrasonic device to the sonic vibro sifter. The output waveband of the digital control power supply can be transmitted to the surface of the screen through the transducer up to 360,000 times/min, ≥500 mesh screening When there is no mesh clogging, no screening efficiency attenuation, and high signal uniformity.

2. This equipment can effectively solve the problem of blocking the mesh caused by the electrostatic adhesion on the mesh, the agglomeration of the powder and the particles inserted into the rough mesh surface, thereby greatly improving the screening efficiency of the cobalt powder.

3. The cobalt powder can be sieved with high precision and multiple levels, effectively improving the qualification rate and production efficiency of the product.

4. Gold can be used in multiple layers (in order to ensure the screening effect, it is recommended not to use more than two layers at most), a set of intelligent ultrasonic generator can use three transducers at the same time.

B.Centrifugal sifter

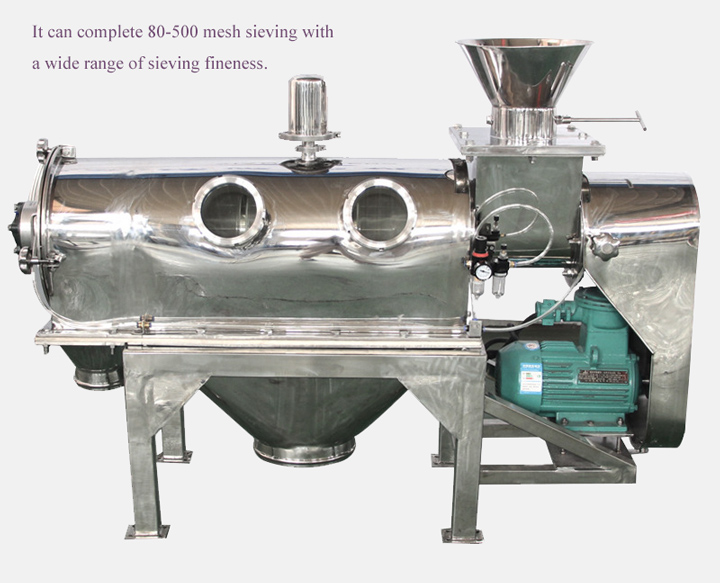

Centrifugal sifter is a fine powder vibro sifter developed and designed by Dahan Machinery in recent years according to market needs. Centrifugal sifter for sieving cobalt powder is a high-tech equipment for high-precision vibrating sieving of fine powders, which can be used in the range of 80-500 mesh Continuous screening of powdery materials, suitable for a wide range of fineness. Its advantages are as follows:

1. High efficiency (the penetration rate can reach 85-95%), and the noise is extremely low.

2. It can complete 80-500 mesh sieving with a wide range of sieving fineness.

3. Good sealing performance, no dust pollution during the screening of cobalt powder.

4. The sieving of cobalt powder can be completed accurately, without over-diameter mixing, and the residue on the sieve is 0.

5. The screen of centrifugal sifter adopts a vertical installation form and does not load, so it has a longer service life and is very convenient to change the screen.

6. Universal wheels can be installed according to customer requirements to facilitate the movement of equipment at any time during production.

If you have problems with the sieving of fine powders like cobalt powder or other operational questions about vibro sifter, please feel free to contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.