Pepper is a commonly used seasoning product. It is inevitable that a small amount of impurities will be mixed in the production. Because it is a product that is directly sold and eaten, it is an indispensable step to remove the impurities. Then how do we choose a suitable sieve For sub-equipment, let’s take a look at it below.

Choosing a suitable screening equipment is closely related to the output of the material to be screened and the size of the particle size of the impurities. Let us give an example below:

Material name: Pepper

Material proportion: 0.6

Material form: dry powder

Ideal processing capacity: 500kg/h

Purpose of sieving: remove large particles of impurities inside, the size of impurities is above 1mm

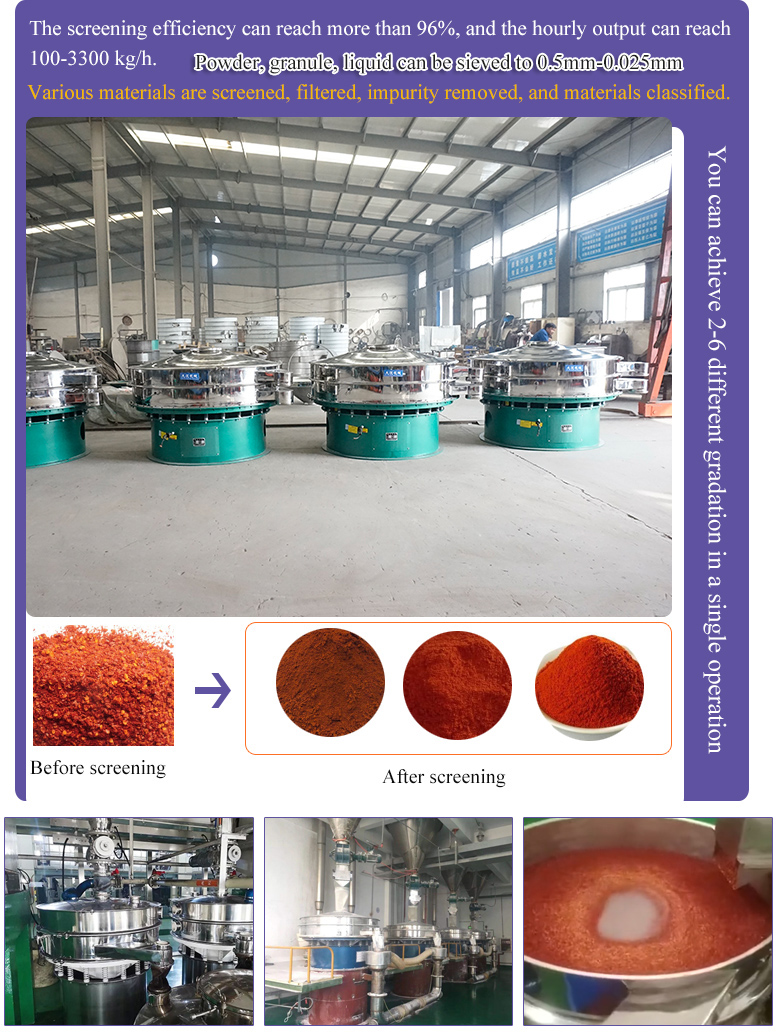

Considering the situation of pepper powder, the technical engineer of Dahan vibro sifter manufacturer recommends the use of DH1000-1Svibro sifter to screen and remove impurities to meet user needs. The screen used is 40 mesh 304 stainless steel woven mesh. Impurities larger than 40 mesh mesh can be directly discharged from the discharge port, and pepper powder smaller than the mesh quickly passes through the screen and is discharged from the lower discharge port. Taking into account the irregular shape of impurities and the possibility of agglomeration of pepper powder to block the net, a suitable number of bouncing balls will be placed under the screen frame of the vibrating screen, and they will continue to hit the screen to clear the net. The bouncing ball is made of silicone material to avoid polluting the pepper. Vibro sifter is designed with a dust cover at the factory to prevent dust. The pepper will not fly during the cleaning process, which will cause the environment to deteriorate. In addition, vibro sifter has a small footprint and low cost, which is even more popular among users.

In order to make the system effective, the powder application system can meet strict quality and production specifications. To ensure the highest product quality by removing excessive contaminants and agglomerates, leaving the required particle size distribution. For this process, the company purchased a combined screening solution that requires a vibro sifter and an ultrasonic deblinding system to prevent pepper from clogging the screen. This will ensure the best results and will not cause any production downtime.

Contact Dahan Machinery to learn more about the various screening and cleaning equipment available in the pepper industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.