The chemical industry includes resins, coatings, industrial medicines, cosmetics, and paints. These materials are more difficult to handle. Therefore, the chemical vibro sifter is a special, high-viscosity, fine-grained material screening and filtering equipment, which is mainly used to screen various chemicals. Materials, such as fine powder, micro powder, dry and wet materials, etc., are suitable for acidic, alkaline, oily and other chemical production.

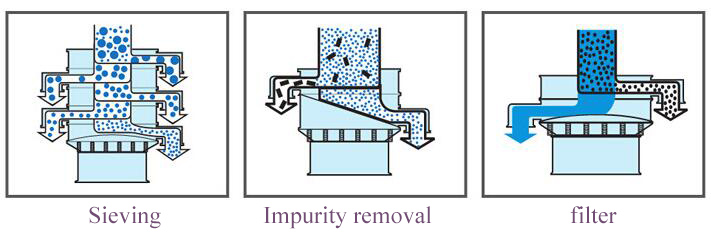

At present, it effectively solves the scheme of screening, removing impurities and filtering materials with oxidized and corrosive steel materials.

To ensure that the material will not deteriorate during the screening process, plastic vibro sifter is also called plastic chemical rotary vibrating screen, plastic chemical vibrating screen, plastic chemical vibrating screen, plastic chemical circular vibrating screen, plastic chemical filter vibro sifter because of the selection of PP plastic material. There are many different names, but the main purpose is to screen and filter the more corrosive materials.

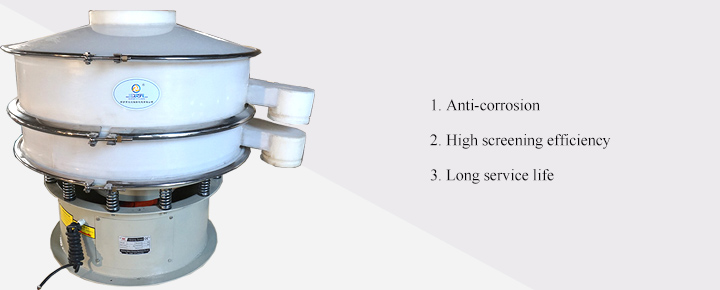

1. Anti-corrosion

The plastic vibro sifter screen is made of nylon material and is made by special processing to meet the screening of acid-base/oxidizing materials. The material will not react, and the screening effect of the material will not be affected.

2. High screening efficiency

Quickly remove the insoluble large particles in some slurry materials, and the filtration capacity can be as high as 20 cubic meters per hour; the plastic vibro sifter processing capacity can reach 1-10T, and the number of screen layers is 1-5.

3. Long service life

The plastic vibro sifter uses a cylindrical eccentric shaft exciter and a partial block to adjust the amplitude. The screen body is made of PP plastic material, which has high corrosion resistance and improves the service life of the product.

The vibro sifter for chemical industry uses a vertical vibrating motor as the vibration source. The eccentric weights on the upper and lower ends of the vibrating motor convert the rotating motion into a horizontal, vertical, and inclined three-dimensional motion, which is transmitted to the nylon screen surface of the vibro sifter; the material passes through The feed inlet enters the equipment. According to different material screening requirements, the material passes through 1-3 layers of nylon screens with different meshes for layering. In this process, a cleaning device located under the screens of each layer ( The bouncing ball) continuously hits the stainless steel screen through frequency vibration, so that the material on the screen can be smoothly screened through the screen, and effectively solves the problem of material blockage. It can also be transmitted to the stainless steel by introducing ultrasonic waves and transmitting high-frequency vibrations through ultrasonic waves. Screen, and then solve the problem of blocking the network, and finally achieve the purpose of screening and removing impurities or filtering and grading, and increase the output.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.