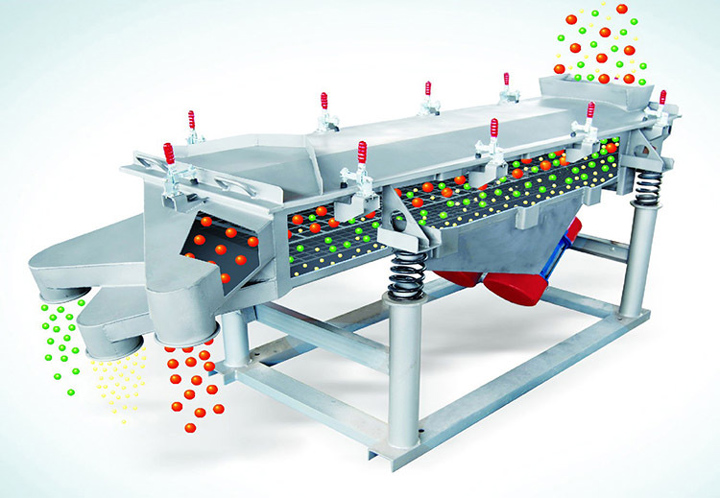

There are many types of vibrating sieve, which are divided into different types according to different uses and screening purposes. This article will introduce the different types of vibrating sieve.

According to the purpose of screening, it can be divided into:

1. Vibrating sieve can be divided into: mining vibrating sieve, light and fine vibrating sieve, experimental vibrating sieve

2. Mine vibrating sieve can be divided into: heavy-duty sieve, custom vibrating sieve, elliptical vibrating sieve, dewatering sieve, circular vibrating sieve, banana sieve, linear vibrating sieve, etc.

3. Light and fine vibrating sieve can be divided into: rotary vibrating sieve, linear sieve, straight row sieve, sonic vibrating sieve, filter sieve, etc.

4. Experiment vibrating sieve can be divided into: slapping sieve, top-strike vibrating sieve, inspection sieve, electric vibrating sieve, etc.

According to the material running track of Xinxiang vibrating sieve, it can be divided into:

According to the linear motion trajectory: linear vibrating sieve (material moves straight forward on the sieve surface).

According to the circular motion trajectory: circular vibrating sieve (materials do circular motion on the sieve surface).

According to the reciprocating motion trajectory: fine screening machine (the material moves forward on the screen surface in a reciprocating motion).

According to the purpose of screening, it can be divided into:

1. Preparation for screening: prepare for the next crusher operation. It is to screen and classify the materials before jigging the ore, and classify and jig the products with different coarse, medium and fine.

2. Pre-screening: Screening before the ore enters the crusher, such as the grid screen installed in front of the coarse crusher, to screen the products under the screen.

3. Inspection and screening: The purpose of screening the ore after crushing is to improve the particle size requirements of the finished material, so that the unqualified crushed ore products can be returned to the crushing operation.

4. Independent screening: The crushing and screening of the crusher separates the finished materials suitable for the user's requirements.

5. Selective screening: Stones with different particle sizes can be obtained by screening and classification, and the low-quality particles can be screened out, thereby correspondingly improving the high-quality materials. Sometimes this screening is called screening.

The above is the introduction of vibrating sieve types. Different vibrating sieves can be selected for different purposes and screening purposes. If you want to know more related information, you can contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.