As a kind of vibrating screen, high-frequency vibrating screen is different from ordinary vibrating screen? Let's find out together:

1. External structure

Ordinary vibrating screen can be installed with multi-layer screen boxes, each layer of screen box has a discharge port, the vibration motor is installed in the box, and the machine base is a circular table-type sealing structure; Material port, one discharge material, one discharge material slag, the motor is installed at the bottom of the screen box, and the adjustable bracket prevents liquid from splashing into the motor, and is suitable for the screening site environment.

2. Applicable materials

The high-frequency vibrating screen is equipped with a high-frequency motor, which has better separation conditions and is suitable for screening slurry materials, such as high-concentration ceramic glaze, paint, etc., can effectively separate slurry and liquid, and is suitable for filtration;

Ordinary vibrating screens use ordinary motors, which are more suitable for screening materials without special circumstances, such as salt, flour, rice, juice and other granules, powders, and liquid materials. It can be filtered by placing only a single-layer screen or a multi-layer screen. Material classification.

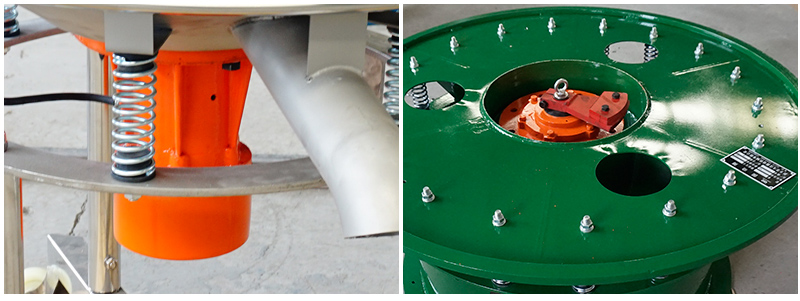

3. Motor

Compared with the ordinary vibrating screen, the vibration motor used in the high-frequency screen is a 2-stage motor, and the speed can reach 3000r/min. When working, it can be vibrated with a screen box at a high frequency and a low amplitude to quickly destroy the surface tension of the material for screening. . The general rotary vibrating screen uses a 4-stage or 6-stage vibration motor, and the speed is only 1000~1500r/min. The material is scattered and screened in a circular shape on the screen surface.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.