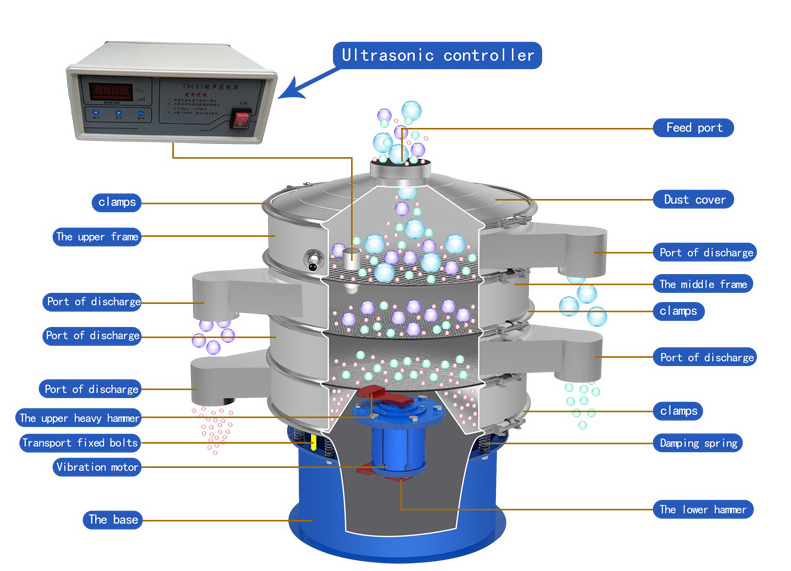

On the basis of ordinary vibrating screen, ultrasonic vibrating screen adds ultrasonic device, thereby increasing the accuracy and efficiency of screening. It has a net cleaning device to reduce the problem of material clogging the screen holes, and can maximize the original characteristics of the material. Its accessories also have many different models. Today, DAHAN Machinery will give you an explanation of the structure of the ultrasonic vibrating screen. I hope it can help to you.

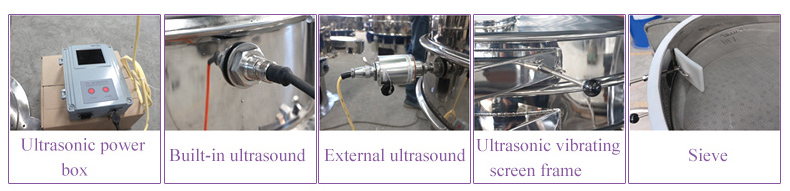

Ultrasonic resonant power supply: 38KHz high-frequency high-power ultrasonic resonant power supply. The built-in microcomputer chip can automatically track the entire digital frequency according to the different states of the ultrasonic wave, without manual adjustment, and the operation is simple and convenient. Long-time working oscillator has low heat generation and stable working state.

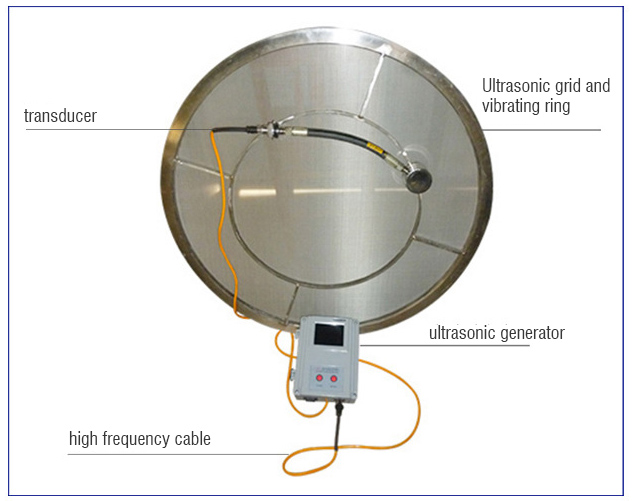

High-frequency connecting line: A cable is used to connect the ultrasonic oscillator and the ultrasonic resonance power supply.

Connectors: Connect plugins.

Oscillator: High-performance ultrasonic transducer.

Ultrasonic grid frame: It is composed of external grid frame and resonance ring.

Screen: Suitable for 10 mesh to 635 mesh.

The above is the introduction of Dahan Machinery to the structure of ultrasonic vibrating screen. Users should choose accessories according to their own needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.