Rotap sieve shaker often appears in university laboratories or research institutes. In addition to screening materials, it is also good at inspecting and grading materials. The rotap sieve shaker is mainly composed of three parts, namely the machine base and the sieve. And the transmission device, in the next time, the editor will analyze the composition of the rotap sieve shaker in depth for you

Rotap sieve shaker parts

1. Transmission

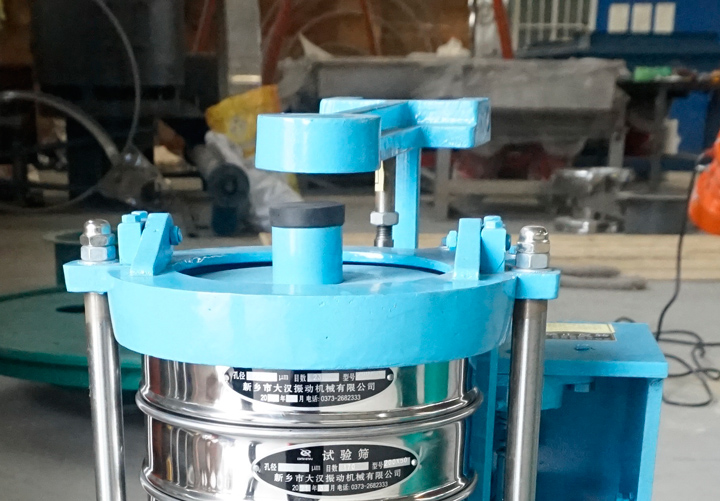

The transmission device refers to the vibration motor, screw, and small hammer iron. The screen is vibrated by the vibration motor. During this process, the small hammer iron above is also beating and beating the top cover, so that the easily blocked materials will vibrate and beat. It disperses and penetrates the mesh smoothly, thereby improving the material screening efficiency.

2. Sieve

The screen mainly refers to the screen frame and screen. The screen frame is made of stainless steel and carbon steel. The screen type includes metal wire, punching plate, electroforming, etc. The mesh size of the woven screen is between 2.36-0.038mm. The mesh of the orifice plate is generally greater than or equal to 3mm, and the mesh of the electroforming screen is generally less than 500mm. In addition, the model and specification of the screen frame and screen, as well as the number of layers, have relevant index standards according to the characteristics of the material, and sometimes can also be adjusted according to the user. needs special customization.

3. Machine base

The machine base includes a base, a tray, a timer, etc. It is mainly used to fix and hold the screen body, and is the most basic equipment of the slap-type vibrating screen. The timer can automatically calculate the material screening time without labor costs.

For more detailed information, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.