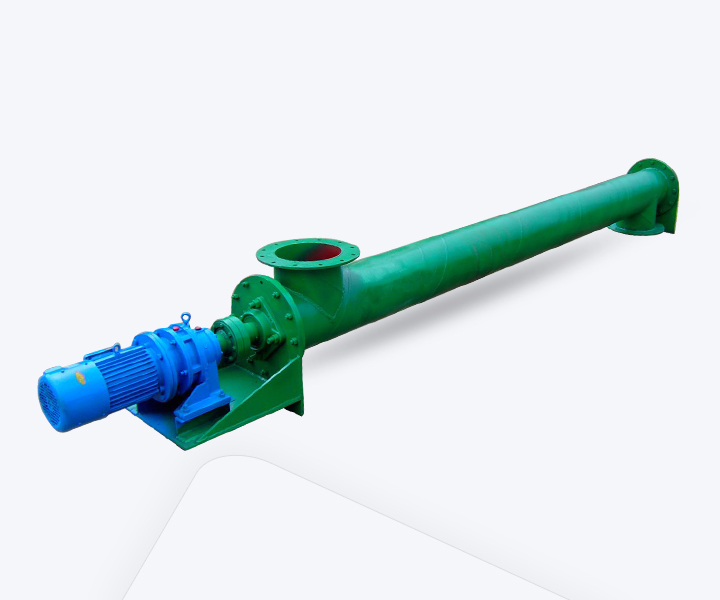

Cement screw conveyor is a kind of equipment used to transport cement. It is easy to block the new town in the process of use. Therefore, I'm here gives you a solution to the cement screw conveyor blocking material, which is convenient for users to timely check cement transportation. Machine blocking problem.

Most of the cement screw conveyors have large requirements on production. Therefore, the power of the conveyor motor is required to be larger than that of the ordinary conveyor. If the power selection is too small, the material transportation will be slower, and the materials will be stacked together. Caused by the phenomenon of blockage.

Solution: Adjust the power of the cement screw conveyor motor to a suitable range, not too large or too small.

Since the cement will condense together when wet, the cement screw conveyor will cause the material to adhere to the middle hanging bearing under the long-term use, and finally the cement screw conveyor will have a problem of blocking.

Solution: Check the cement screw conveyor in time, and carry out necessary finishing of the cement entering the conveyor to avoid large impurities or fibrous impurities entering the machine to cause blockage.

The gap between the blades of the screw screen screw conveyor is relatively large due to the large amount of cement screw conveyor, and the cement conveying process is more complicated. If the pitch of the screw conveyor is too small, it is easy to cause blockage.

Solution: The cement screw conveyor blades should adopt a gradual pitch, and the pitch from the feed port to the discharge port is large.

Due to the relatively large requirements of cement conveying capacity and the combination of cement properties, in the design of screw conveyors, the angle of inclination should not be too large under normal circumstances. If the angle of inclination of cement screw conveyor is too large, it is easy to cause screw conveying of cement returning material. The machine is blocked.

Solution: The inclination angle of cement screw conveyor is not too large, generally 30 degrees is best. If the angle is too large, it should be proposed before ordering, and choose high-power electric drive.

Cement transportation sites are generally outdoors, so in extreme weather, it will also affect the conveyor. For example, if there is rain, the cement will condense into a block when it meets water, which will easily block the screw conveyor.

Solution: Avoid operating the machine under the harsh conditions. In addition, if the cement screw conveyor is blocked due to water, it should be cleaned in time.

The above is the solution to the cement screw conveyor blocking material, hope to help you, if you want to know more, you can click on the online consultation to get relevant information, there will be a professional technical staff to give you a comprehensive introduction.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.