Sieve silicon carbide powder, the material is damp. Ordinary vibrating sieve can easily block the sieve. It needs 3 tons per hour, 200 mesh, 20% larger than 200 mesh, but there are loose clusters, which can be opened with a twist of the hand.

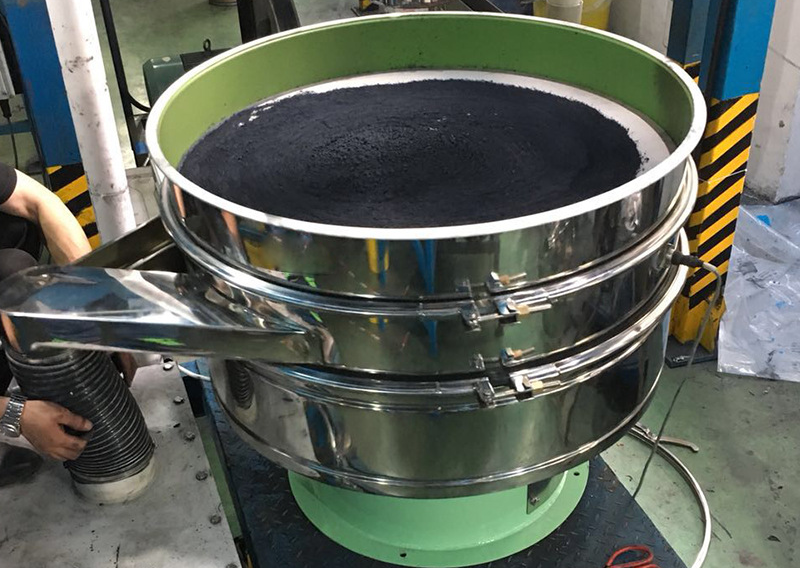

Recommended products: ultrasonic vibrating sieve

The mesh number of the sieve is 80 mesh to 625 mesh, which can sieve most of the fine powder and silicon carbide powder. (Ultrafine silicon carbide powder 1000 mesh, 1500 mesh and above ultrasonic vibrating sieves cannot be processed).

According to the customer's material situation, if a sieveing machine is required, then the ultrasonic vibrating sieve is undoubtedly the best choice.

1. The 80-625 mesh sieve can meet the sieveing requirements of silicon carbide powder of 200 mesh and above;

2. Do not block the mesh. The ultrasonic vibrating sieve can generate high-frequency mechanical vibration of 36KHz, and the high-frequency vibration is equivalent to having its own cleaning device, which can avoid the blockage of silicon carbide powder;

3. Can break false agglomerates. The customer's silicon carbide powder is loose and agglomerated due to moisture, so the high-frequency vibration of the ultrasonic vibrating sieve can be used to disperse the agglomeration and improve the passing rate of the silicon carbide powder. Compared with the ordinary vibrating sieve, the sieve surface passing rate of the ultrasonic vibrating sieve can be increased by 50%-400%, and the hourly output can easily reach 3 tons (up to about 18 tons/hour).

Address:China,Yanjin county forest park gate to the west 1000 meters north road.