Maltodextrin is a common food additive used as a thickener, stabilizer and filler in various foods. Maltodextrins are typically produced by hydrolyzing starch, which results in a mixture of glucose polymers of different lengths, and screening maltodextrins is an important step in the manufacturing process, ensuring that the final product is high quality, consistent and safe to eat , Sieving machine is commonly used in various applications in the maltodextrin industry, such as quality control, safety screening, grading and grading of maltodextrin granules.

1. Powder classification: It can be used for the separation of large and fine maltodextrin particles, which can ensure that the final product is uniform and does not contain any impurities.

2. Quality control: used to control the quality of raw materials used in the maltodextrin industry. They can help identify and remove any contaminants or foreign particles that may be present in the raw material.

3. Safety screening: use sieving machine to ensure that the final product of maltodextrin is safe to eat. They can help remove any sharp or hazardous materials that may be in the product.

4. Formulation development: sieving machines can be used in the formulation development process to ensure that ingredients are properly mixed and blended. They can also help determine the optimum particle size distribution for a particular maltodextrin product formulation.

5. Packaging: sieving machines can be used to ensure that packaging materials used by the maltodextrin industry are free of any contaminants or particles that could be harmful to consumers.

Maltodextrin screening presents several challenges, including:

1. Particle Size: Maltodextrin particles can vary in size, making it difficult to achieve a consistent particle size distribution. This affects the performance and quality of the final product.

2. Clogging: Maltodextrin granules are easy to clog or block the sieve, especially when sieving fine powder. This reduces the efficiency of the screening process and requires frequent cleaning or maintenance.

3. Static electricity: Maltodextrin particles will generate static electricity during the screening process, which will make the particles stick together and block the screen. This is especially challenging when sieving fine powders.

4. Contamination: Maltodextrin is susceptible to contamination by foreign matter such as dirt, dust and debris. This affects the purity and safety of the final product.

5. Hygroscopicity: Maltodextrin is hygroscopic, that is, it can absorb moisture from the air. This can cause particles to clump together, making it difficult to achieve a consistent particle size distribution.

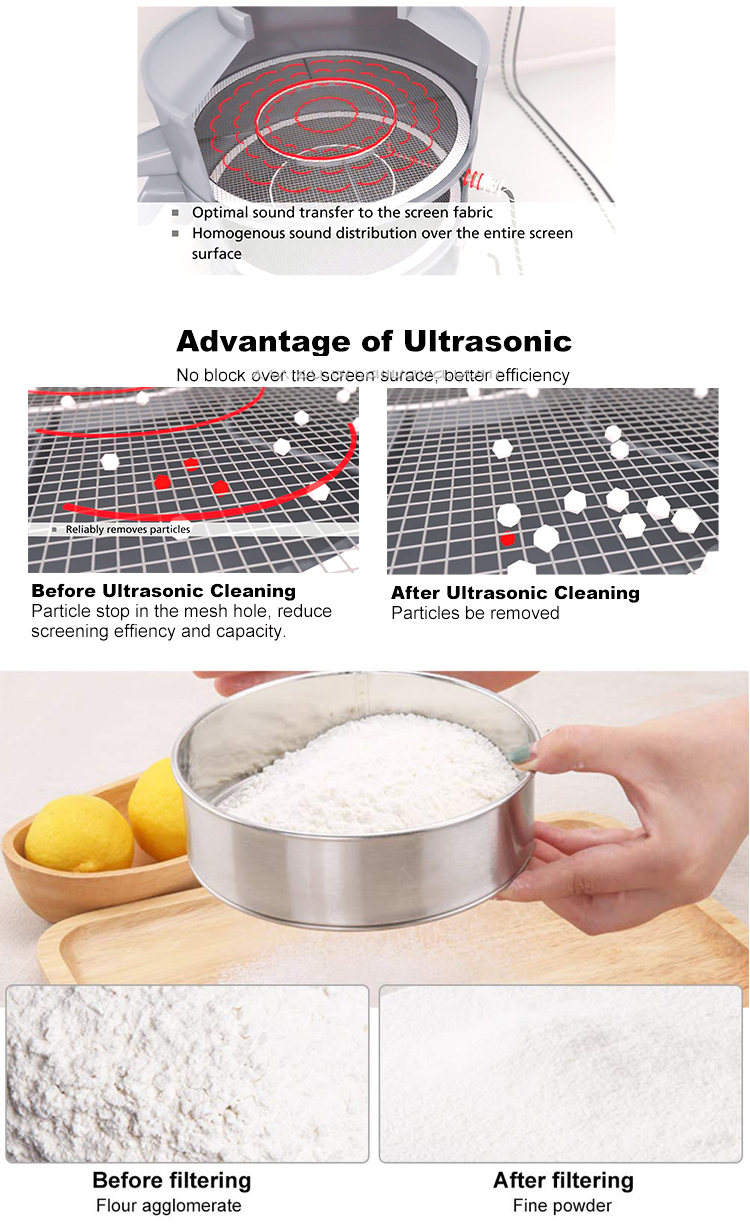

Overall, the challenges associated with maltodextrin screening require careful attention to the screening process to ensure that the final product is of high quality, consistent and safe to eat. This may involve the use of specialized equipment, such as ultrasonic sieving machines, and careful control of sieving parameters such as mesh size and vibration frequency. The following are the advantages of ultrasonic sieving machine in sieving maltodextrin:

1. Improve screening efficiency: Ultrasonic screening machine can improve the screening efficiency of maltodextrin by reducing the friction between the particles and the screen. This helps prevent particles from clogging the screen and increases the throughput of the machine.

2. Unblinding: Can remove particles that may be trapped in the screen, thus helping to prevent the screen from clogging or clogging. This means that the ultrasonic screen can run continuously without frequent cleaning or maintenance.

3. Particle size control: helps to separate maltodextrin particles according to particle size, so as to obtain more accurate particle size distribution. This is important to ensure the final product has the desired texture, mouthfeel and performance.

4. Since the screen blockage is eliminated, the product quality remains consistent throughout the production process, and there is no need to stop the machine to clean the screen, reducing the risk of machine downtime and reducing production costs.

1. Particle size range: The sieving machine should be able to accurately and efficiently separate maltodextrin according to the particle size range. The particle size range of maltodextrin can vary depending on the specific application, so it is important to choose a machine that can handle the required particle size range.

2. Capacity: There should be enough capacity to handle the required volume of maltodextrin. The capacity of a machine can vary depending on the size and type of machine, so it is important to choose a machine that can handle the required volume.

3. Materials of Construction: Shall be made of materials suitable for use with maltodextrin. Stainless steel is often the material of choice due to its corrosion resistance and hygienic properties.

4. Screening options: There should be multiple screening options to tailor to the specific size range of the maltodextrin granules.

5. Easy to clean: It should be easy to clean to prevent cross-contamination and ensure the purity of maltodextrin.

Overall, the choice of sieving machine for maltodextrin will depend on the specific requirements of the application. Consider factors such as particle size range, capacity, materials of construction, screen options and ease of cleaning to make an informed decision.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.