Metal alloy powder vibrating screen is screened and graded by a screening machine. To get the required screening, the powder needs to be dry and. According to the actual situation of our company's previous customers, customers who need to remove impurities in large-particle alloy powder can achieve the customer's expected 800kg per hour, and the dry mesh number is 500 mesh.

Metal alloy powder vibrating screen is a metal powder formed by partial or complete alloying of two or more components. Completely alloyed powder exists in the form of solid solution and intermetallic compound. Alloy powder is generally divided into five grades: coarse powder, medium powder, fine powder, and ultrafine powder.

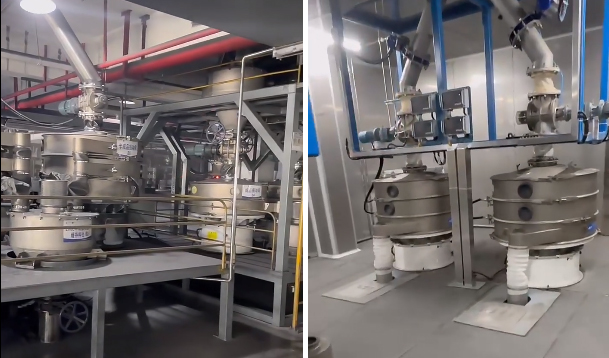

Metal alloy powder vibrating screen is a vibration screening equipment specially used for screening metal alloy powder, mainly used in powder metallurgy, 3D printing, surface coating and other fields. Its core functions and advantages include:

Particle size control: Metal alloy powder vibrating screen can accurately screen and grade metal alloy powder. By selecting the appropriate screen aperture and adjusting the vibration parameters, the required particle size distribution can be obtained to ensure that the powder composition of the metal alloy meets the requirements.

Reducing dust pollution: During the screening process, the generation and diffusion of dust can be effectively controlled, the impact of dust on the production environment and operators can be reduced, and the cleanliness and safety of the working environment can be improved.

Energy saving: Usually, power devices such as motors or vibrators are used. Compared with other screening methods, energy consumption is lower and production efficiency is improved.

Good repeatability: Through reasonable screening parameters and operation control, the screening effect of metal alloy powder can be stably achieved to ensure the consistency of product quality.

Metal material preparation: Used in the preparation process of metal materials, metal alloy powders are screened and graded to control particle size distribution and quality.

Additive production: It plays a key role in the production of additives, and additive powders with a particle size range that meets the requirements are obtained through screening.

Powder metallurgy: In the powder metallurgy industry, it is often used to screen and grade metal alloy powders to meet different process requirements.

3D printing: In the process of metal 3D printing, it is used to screen metal alloy powder, remove particulate impurities, and ensure the uniformity and stability of powder during the printing process.

The structure of the metal alloy powder vibrating screen includes components such as screen box, screen mesh, vibration device, feed port, discharge port and bracket base. The screen box is a closed container, usually made of metal, with sufficient strength and rigidity; the screen mesh is located inside the screen box, made of metal wire or synthetic material, with different apertures for separating metal alloy powders of different particle sizes; the feed port and discharge port are used to import and export powders respectively.

As an important powder screening equipment, the metal alloy powder vibrating screen plays a key role in the production process of metal alloy powder. Its efficient screening ability, precise grading effect and stable and reliable operation characteristics make it an indispensable equipment in the metal alloy powder production line, which helps to improve product quality, production efficiency and reduce production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.