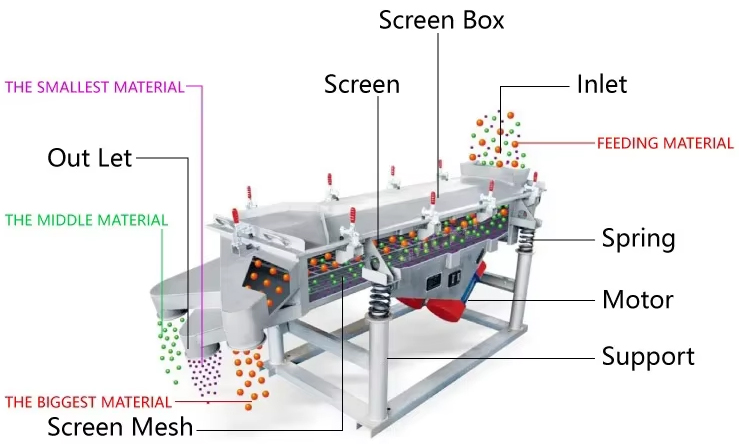

Linear vibration machine screening, also known as linear vibration screen, is a screening device that uses the exciting force generated by the vibration motor to make the material be thrown up on the screen and move forward in a straight line, thereby achieving the purpose of screening and grading the material. This screening machine has the characteristics of low energy consumption, high output, simple structure, easy maintenance, and fully enclosed structure without dust dispersion. It is very suitable for assembly line operation and can automatically discharge materials. It is widely used in coal, hydropower, mining, building materials, chemicals, plastics, abrasives, medicine, food, carbon, fertilizer and other industries.

The working principle of Linear vibration machine screening is based on the exciting force generated by the vibration motor. When the two vibration motors rotate synchronously and in opposite directions, the exciting forces generated by their eccentric blocks offset each other in the direction parallel to the motor axis, and superimposed in the direction perpendicular to the motor axis to form a resultant force. This resultant force makes the motion trajectory of the screening machine a straight line, and the material is thrown up on the screen surface and moves forward in a straight line, thereby achieving the purpose of screening and grading.

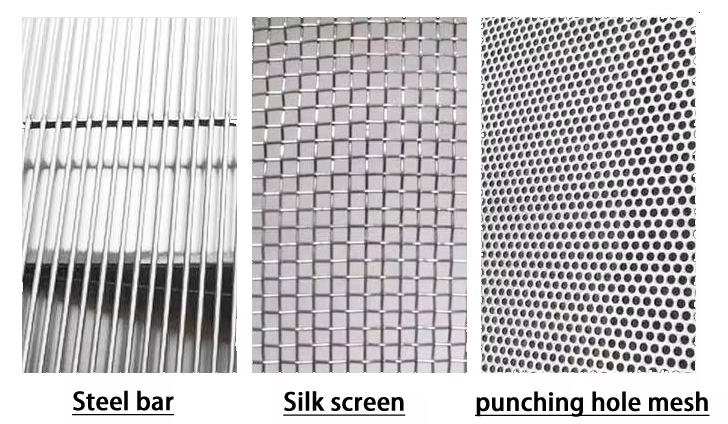

Screen plate: The screen plate is the surface on which the material is placed for screening. It consists of multiple layers of screen plates with different mesh sizes to allow particles of various sizes to pass through.

Vibration motor: The vibration motor provides the necessary vibration movement for the screen plate. The motor generates linear vibrations to move the material along the screen surface.

Screen surface: The material is evenly distributed on the screen surface. When the screen plate vibrates linearly, particles smaller than the screen holes pass through, while larger particles remain on the screen.

The structural features of linear vibration machine screening include the screen box is usually welded from steel plates, which has high strength and rigidity and can withstand large vibration forces and material impact. The screen is an important part of the equipment and is usually made of high-strength metal wire or polymer material. It is wear-resistant and high-temperature resistant. Different specifications of screens can be selected according to different screening requirements. In addition, the linear vibration screening machine is also equipped with a vibration reduction device to reduce the impact of vibration transmission to the surroundings of the equipment, ensure the stable operation of the equipment and reduce noise.

High efficiency: The linear movement and design of the screen plate ensure efficient and accurate screening of materials.

Uniform screening: Linear vibration motion helps to evenly distribute and screen materials on the screen surface.

Versatility: It can handle a variety of materials, including dry, wet, fine and coarse particles.

Low maintenance: Linear vibrating screens are relatively easy to maintain and operate, and maintenance tasks require minimal downtime.

High capacity: These machines are able to handle large amounts of material due to their high screening capacity.

Linear vibration machine screening is widely used in many industries such as mining, metallurgy, and building materials. In the mining industry, it is used for processes such as ore screening and coal screening; in the metallurgical industry, it is used for screening and grading of ores such as iron ore and copper ore; in the building materials industry, it is used for screening and grading processes of materials such as sand, gravel, cement, and concrete, ensuring the quality and consistency of the products. Through its unique working principle and structural characteristics, the linear vibration screening machine is able to quickly screen and grade a variety of materials, improve production efficiency, and improve product quality.

Linear vibration machine screening is a versatile and efficient screening solution for material separation in various industries. Proper maintenance and operation of these machines can increase productivity, screening accuracy, and equipment life.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.