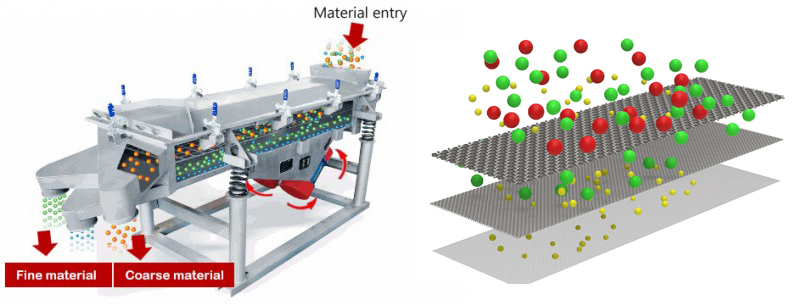

Using linear vibration to convey and separate bulk materials

![]()

![]()

![]()

Price:$580.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

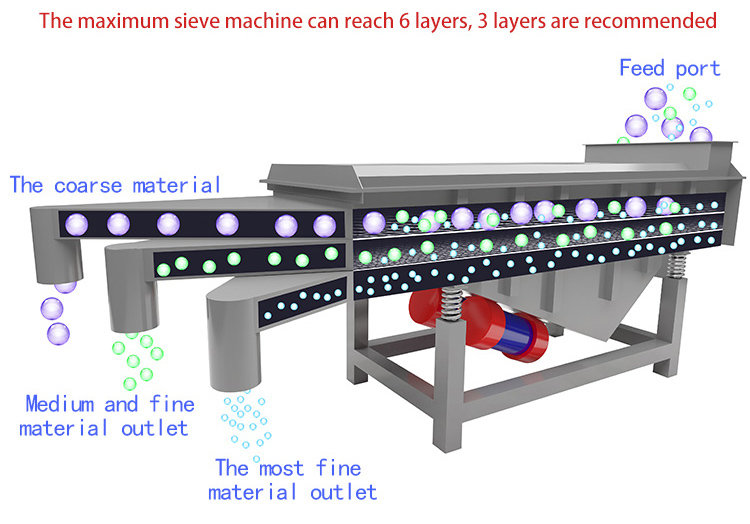

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Applications: Designed to remove oversized particles, impurities and other foreign matter, the multi-layer system can separate products into 2, 3, 4, 5, 6 or 7 different grades.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Linear motion vibrating screen is a type of vibrating screen that utilizes linear vibration to convey and separate bulk materials. It operates by applying a vibrating force to the screen panels, causing them to move in a linear motion along the direction of the vibrating excitation. This linear motion helps to efficiently convey and separate the materials on the screen surface.

Linear motion vibrating screen is available in single-layer, double-layer and multi-layer screens. It can complete grading of 7 different specifications in one operation. The mesh size ranges from 3/8 inches (10 mm) to 400 mesh (38 microns). , can provide a screening area of 500mm to 1500mm wide and 1500 to 4000mm long, with a processing capacity of up to 20 tons/hour, and can be customized according to customer requirements.

Linear motion vibrating screen uses a vibrating motor as the source of vibration to generate upward and forward forces, forcing the material to be quickly thrown up on the screen, and at the same time pushing the material forward for a straight tumbling motion. After the material enters the feed port of the sieving machine, it passes through one or more layers of screens to simultaneously produce one or several specifications of oversieve (materials larger than the sieve aperture) and under-sieve (materials smaller than the sieve aperture) , And discharge the body from their respective discharge ports.

High screening efficiency

Compared with other types of vibrating screens, linear motion vibrating screens have a larger screening area. This increases screening efficiency, resulting in better separation and classification of materials.

Precise particle size

The linear motion and multi-layer design of these screens allow for precise particle sizing and classification. Different mesh sizes on each screen plate ensure accurate separation of materials based on their size.

Improve productivity

With its efficient screening capabilities, linear motion vibrating screens can separate materials quickly and accurately, helping to increase overall productivity. This increases process efficiency and reduces downtime.

Reduce noise levels

Linear motion vibrating screens often have noise reduction features, such as rubber isolators or spring suspensions, to minimize operating noise. This creates a quieter work environment and improves the overall workplace experience.

Easy to integrate

Linear motion vibrating screens can be easily integrated into existing production lines or processing systems. They can be used as stand-alone units or combined with other equipment to create complete material handling and screening solutions.

Customizable design options

Linear motion vibrating screens can be customized to meet specific application requirements. They can be designed with different screen sizes, deck configurations, and vibration parameters for optimal performance in specific material handling processes.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

The structure of a linear motion vibrating screen typically consists of the following components:

Screen Box: The screen box is the main component of the vibrating screen and serves as the container for the material being screened. It is usually made of steel and is equipped with screen panels or decks. The screen box is designed to withstand the forces generated by the vibrating motion.

Vibrating Motor: The vibrating motor is responsible for generating the linear vibrations that drive the screen box. It is typically located at the center of the screen box and is mounted with eccentric weights. The rotation of the motor generates centrifugal forces, causing the screen box to vibrate in a linear motion.

Vibration Isolation System: To minimize the transmission of vibrations to the surrounding structure, a vibration isolation system is often employed. This system consists of rubber springs or other damping elements that absorb and dampen the vibrations, reducing noise and preventing excessive vibration transmission.

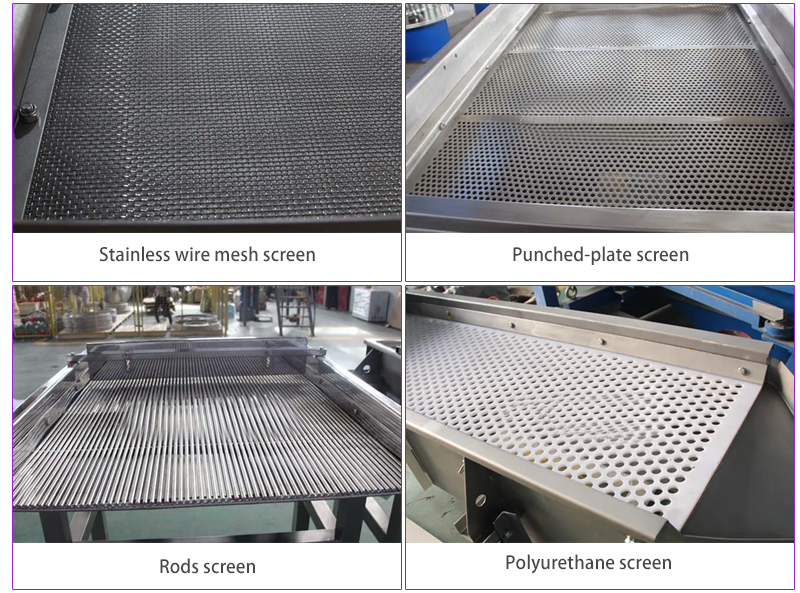

Screen Panels or Decks: The screen panels or decks are the surfaces on which the material is screened. They are usually made of wire mesh or synthetic materials with specific opening sizes to allow for the desired particle separation. The number of screen decks can vary depending on the application requirements.

Support Structure: The support structure provides stability and rigidity to the vibrating screen. It is typically made of steel and includes beams, cross members, and support legs. The support structure is designed to withstand the dynamic loads and vibrations generated during operation.

Linear motion vibrating screens find applications in various industries for efficient screening and separation of materials. Some common applications include:

Mining and Quarrying: Linear motion vibrating screens are widely used in the mining and quarrying industry for screening and classifying various types of ores, minerals, and aggregates. They can efficiently separate particles based on size and remove unwanted fines, improving the quality of the final product.

Recycling: Linear motion vibrating screens are used in recycling plants to separate and classify recyclable materials such as plastics, paper, glass, and metals. They help in the efficient sorting and segregation of different materials, enabling effective recycling processes.

Chemical Industry: Linear motion vibrating screens are utilized in the chemical industry for screening and grading chemical powders, granules, and liquids. They help in removing oversized particles and impurities, ensuring the desired particle size distribution and product quality.

Food Processing: Linear motion vibrating screens are employed in the food processing industry for screening and grading food products such as grains, powders, and ingredients. They help in removing foreign particles, ensuring product purity, and achieving consistent particle sizes.

Pharmaceuticals: Linear motion vibrating screens are used in pharmaceutical manufacturing for screening and separating pharmaceutical powders, granules, and tablets. They help in removing oversized particles, ensuring uniformity, and maintaining product quality.

Construction Materials: Linear motion vibrating screens are utilized in the construction materials industry for screening and separating materials such as sand, gravel, crushed stone, and concrete aggregates. They help in achieving the desired particle size distribution and removing impurities.

Chemical Fertilizers: Linear motion vibrating screens are employed in the fertilizer industry for screening and classifying chemical fertilizers. They help in separating different grades of fertilizers based on size, ensuring uniformity, and improving the efficiency of fertilizer production.

Xinxiang Dahan Linear Motion Vibrating Screen, as a manufacturer of vibrating screens, has 15 years of rich experience and expertise. They have an in-depth understanding of the design, manufacturing and application of vibrating screens and are able to provide high-quality products and solutions. They have the ability to customize vibrating screens and provide customized designs and configurations based on customers' specific needs and application scenarios. This ensures that the vibrating screen is optimally adapted to the customer's production process and material handling requirements. We have a professional technical team that can provide customers with installation, commissioning, maintenance and troubleshooting support to ensure the normal operation of the vibrating screen and customer satisfaction.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.