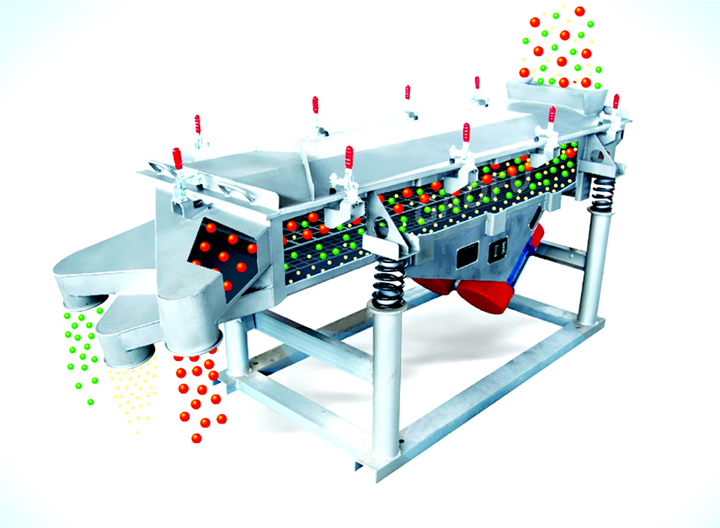

Kaolin vibrating screen is used to grade kaolin between 80-700 meshes, and to screen and grade kaolin through a vibrating screen to remove impurities. Different particles or powdered kaolin can be divided into 1 to 6 different finished materials. Its working principle is to use an upright motor as an excitation source, and eccentric weights are installed at the upper and lower ends of the motor to convert the motor's rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmit it to the screen surface. The material enters the equipment through the feed port and is screened through screen layers of different mesh sizes, ultimately achieving the purpose of screening and impurity removal or filtering and grading.

Vibrating screen: The key component of the kaolin vibrating screen is the vibrating screen. Through high-frequency vibration, kaolin is screened on the screen to separate kaolin of different particle sizes.

Grading and removal of impurities: The vibrating screen divides kaolin into different levels according to its particle size and shape, and removes impurities such as impurities and particles to ensure product quality.

Adjustment device: The vibrating screen is usually equipped with an adjustment device to adjust the vibration frequency and amplitude to adapt to kaolin of different particle sizes and production needs.

High efficiency: The design is exquisite and durable, suitable for the screening needs of various powders and particles.

Low noise: The fully enclosed structure design is simple to operate and easy to clean.

Easy to change the net: It only takes 3-5 minutes to quickly change the net, which is suitable for screening needs of different mesh sizes.

No blocking of the net: The net cleaning device (such as bouncing ball) effectively solves the problem of material blocking of the net.

Wide range of application: Suitable for screening and filtration of materials such as particles, powders, and mucus.

Kaolin vibrating screen is widely used in the screening process of kaolin. Since kaolin is easy to disperse and suspend in water, wet screening is usually used. First, the kaolin ore is made into a slurry with micron-sized particles, and a dispersant is added to dissociate the mineral in water. Then, it is screened through a vibrating screen to screen out the pure kaolin ore.

Kaolin vibrating screen plays an important role in the kaolin processing industry. By screening, grading and removing impurities, it improves product quality, production efficiency and processing technology accuracy.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.