Ultrasonic vibrating screen is a device that uses ultrasonic waves for screening, which can achieve efficient and fine screening work. Iron oxide is a common material with good magnetism and wear resistance, and is often used in the preparation of magnetic materials and as a carrier for catalysts.

Ultrasonic vibrating screen can be used in the processing and screening of iron oxide in various industries. The following are some specific applications of ultrasonic vibrating screens in iron oxide:

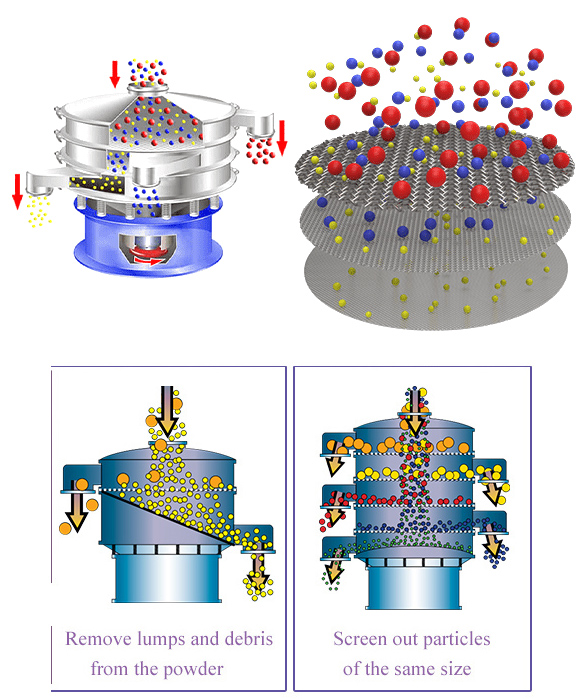

1. Particle size classification: Iron oxide particles can be accurately divided into parts of different sizes to ensure the uniformity and consistency of the final product.

2. Quality control: It can remove oversized or undersized particles, impurities and aggregates in iron oxide powder, thus contributing to quality control. This ensures that the final product meets the required specifications and quality standards.

Iron oxide for ultrasonic vibrating screen can be applied in many fields. For example, in ore processing, the combination of ultrasonic vibrating sieve and iron oxide can be used to achieve efficient separation of magnetic minerals in ore; in the preparation of catalysts, ultrasonic vibrating sieve can be used to fix iron oxide on the carrier to increase the amount of catalyst activity and stability.

As one of the vibration sources of the ultrasonic vibrating screen, iron oxide for ultrasonic vibrating screen has the following advantages:

1. High-frequency vibration: Iron oxide for ultrasonic vibrating screen adopts high-frequency vibration, which can reach a frequency of tens of kilohertz, which is higher than the traditional vibrating screen. High-frequency vibration can increase the screening effect, improve screening accuracy and productivity.

2. Finer sieving: The particle size of iron oxide powder is very small, generally at the nanometer level. Ultrasonic vibrating sieves have a high vibration frequency and can achieve finer screening, and can control the particle size below a few microns.

3. Good anti-clogging properties: Iron oxide is a substance with good anti-clogging properties. In the sieve holes of the vibrating sieve, the particle shape of iron oxide is uniform, and it is not easy to gather and block the sieve holes, and will not affect the screening effect.

4. High temperature resistance: Iron oxide can be sieved under high temperature environment. Ultrasonic vibrating screens generally have the characteristics of high temperature resistance, so that they can perform vibration screening under high temperature conditions, and are suitable for screening high temperature materials such as iron oxide.

5. Energy saving and environmental protection: Ultrasonic vibrating screens use ultrasonic oscillators as energy sources, which can effectively reduce energy consumption and improve energy utilization. Compared with traditional vibrating screens, ultrasonic vibrating screens have lower noise and vibration amplitude, and have less environmental pollution.

It is important to note that specific applications and iron oxide particle size requirements may vary by industry and purpose of use. Ultrasonic vibrating screens can help achieve accurate particle size control, improve efficiency, and enhance the quality of iron oxide in a variety of applications. If you are looking for screening equipment, please feel free to contact Dahan Machinery, we will recommend suitable screening solutions for you according to your needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.