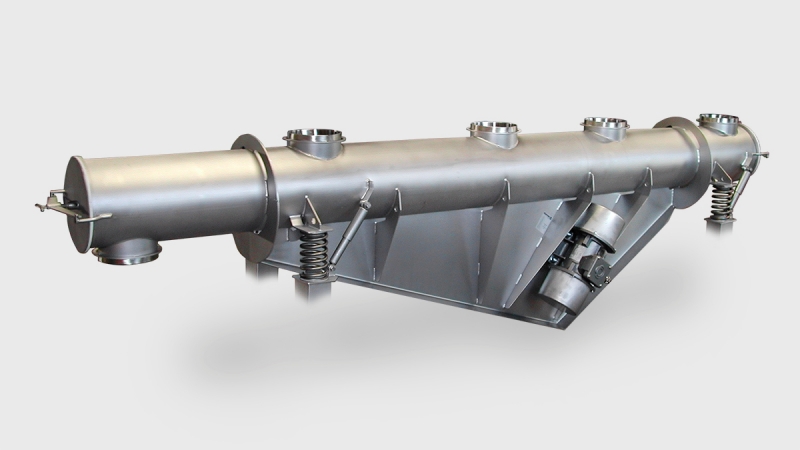

Tube vibrating conveyor is a material conveying equipment widely used in industrial production. It conveys materials along the pipe through vibration force. This kind of conveyor has the advantages of simple structure, stable operation, and long transportation distance. It is widely used in mining, metallurgy, chemical industry, building materials and other industries. The working principle of tube vibrating conveyor is based on the transmission of vibration force and the flow characteristics of materials. The entire conveying system consists of vibration generators, pipes and support structures.

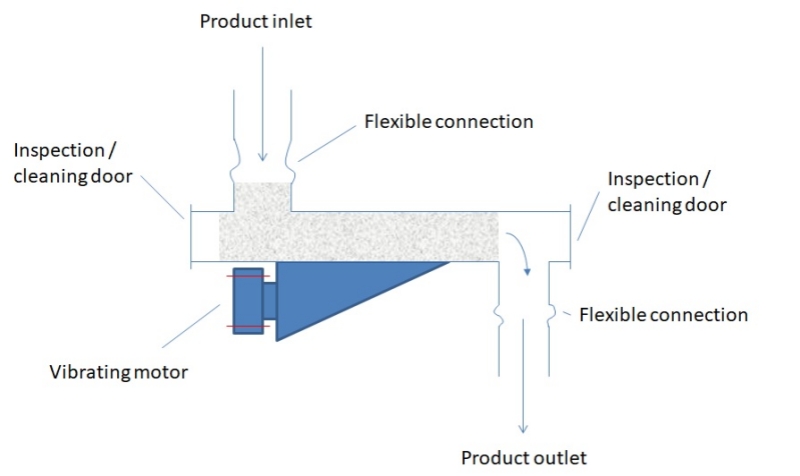

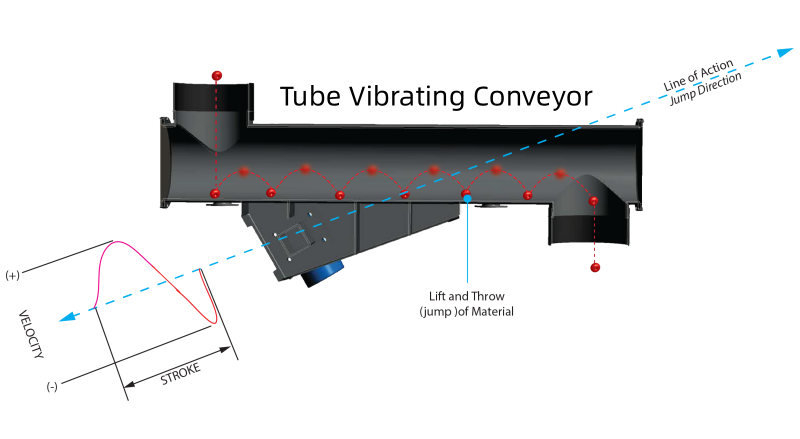

First, the vibration generator generates vibration force. Vibration generators usually consist of motors and vibration devices. The motor generates vibration force by driving the vibration device, and the vibration force is transmitted to the pipes and materials. When the vibration force is transmitted to the pipe, the pipe starts to vibrate. The vibration force causes the pipeline to vibrate periodically, which can be horizontal, vertical or a combination of both. Under the action of vibration force, the material in the pipe begins to flow.

There are two main ways of material transportation on tube vibrating conveyor: plug flow and spiral flow.

In plug flow, the material forms a dense material column in the pipe, and the material moves forward with the vibration of the pipe. When the vibration force of the pipe exceeds the internal friction of the material, the material starts to move. The flow speed and conveying capacity of materials depend on the size and frequency of the vibration force, as well as the properties of the materials.

In spiral flow, material flows along a spiral path. The vibration force of the pipe causes the material to form a spiral flow state in the pipe, and the material advances along the spiral path. Spiral flow can effectively improve the material conveying capacity and mixing effect.

The following points need to be paid attention to during the working process of tube vibrating conveyor: control the size and frequency of vibration force to adapt to the transportation requirements of different materials. Excessive vibration force may cause the material to be blocked or excessively broken, while too small a vibration force may cause the material to fail to flow smoothly.

The design and layout of pipelines must be reasonable to ensure smooth flow and stable transportation of materials. The diameter, length, angle and other parameters of the pipeline need to be reasonably selected according to the nature of the material and the transportation requirements. Regularly inspect and maintain vibration generators and pipes to ensure proper operation. Clean the accumulation and impurities in the pipeline to keep the conveying system in good condition.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.