Garnet sand is a valuable abrasive material widely used in various industries such as metalworking, construction, and waterjet cutting. To ensure the quality and consistency of garnet sand, it is crucial to have an efficient method of separating impurities and grading the particles. In this regard, the garnet sand vibratory sifter plays a vital role. This article explores the features, benefits, and applications of the garnet sand vibratory sifter in enhancing material separation and efficiency.

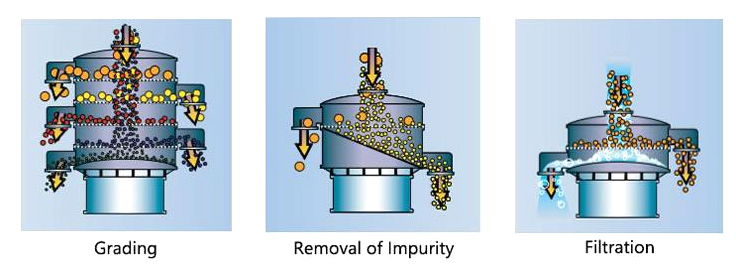

Garnet sand for Vibratory sifter is a specialized machine designed to effectively separate impurities and grade garnet sand particles. It employs the principle of vibration to achieve efficient material separation. The sifter consists of a vibratory motor that generates vibrations, causing the garnet sand to move along the sieve surface. This motion allows the smaller particles to pass through the sieve, while larger particles and impurities are retained.

High Separation Efficiency: The garnet sand vibratory sifter ensures high separation efficiency by effectively removing impurities and grading the sand particles according to size. This results in a more uniform and consistent garnet sand product.

Adjustable Sieve Deck: The sifter is equipped with an adjustable sieve deck, allowing operators to customize the size of the sieve openings. This flexibility enables precise control over the grading process, accommodating different particle size requirements.

Easy Maintenance: The vibratory sifter is designed for easy maintenance. It features a removable sieve deck and quick-release clamps, facilitating convenient cleaning and replacement of the sieve mesh. This ensures optimal performance and extends the lifespan of the equipment.

Durable Construction: The garnet sand vibratory sifter is constructed with robust materials, including stainless steel, to withstand the abrasive nature of garnet sand. This ensures long-lasting durability and reliable operation even in demanding industrial environments.

Garnet Sand Production: The vibratory sifter plays a crucial role in the production of garnet sand by efficiently separating impurities such as dust, dirt, and oversized particles. This results in high-quality garnet sand suitable for various applications.

Waterjet Cutting: Garnet sand is commonly used as an abrasive material in waterjet cutting machines. The vibratory sifter ensures that the garnet sand used in the cutting process is properly graded, allowing for precise and consistent cutting performance.

Surface Preparation: In surface preparation applications such as sandblasting, the garnet sand vibratory sifter helps ensure that the sand particles are free of impurities, providing a clean and uniform surface for coating or painting.

The garnet sand vibratory sifter is a valuable tool in the garnet sand industry, enabling efficient material separation and grading. With its high separation efficiency, adjustable sieve deck, easy maintenance, and durable construction, it enhances the quality and consistency of garnet sand products. Whether in garnet sand production, waterjet cutting, or surface preparation, the vibratory sifter plays a crucial role in achieving optimal results.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.