Frankly speaking, the basic principles of the two are the same. Both use a vertical motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion. , And then transfer this movement to the screen surface to achieve the effect of screening materials.

But ultrasonic vibro sifter is a subdivision of traditional vibro sifter, and the two are still very different.

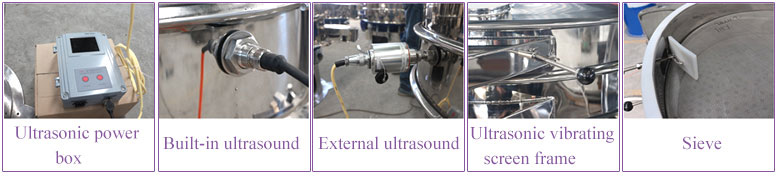

From the most intuitive point of view, ultrasonic vibro sifter has one more ultrasound instrument than traditional vibro sifter, equipped with an ultrasonic screening and cleaning system, which can be combined with various types of vibro sifter extensions.

The ultrasonic vibro sifter is to convert 220v, 50HZ or 110v, 60HZ electric energy into 38KHZ high frequency electric energy, input the ultrasonic transducer, turn it into 38KHZ mechanical vibration, so as to achieve the purpose of efficient screening and cleaning.

In the traditional vibro sifter, a vertical motor is used as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights, which convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to Screen surface. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

The filtering performance of ultrasonic vibro sifter is better, because it makes the screen superimpose high-frequency ultrasonic vibration while being subjected to low-frequency vibration, so that the large particles on the screen are suspended, so as to avoid clogging the mesh. It has the advantages of self-cleaning function and non-clogging of the mesh, no need to add anti-blocking devices such as bouncing balls.

The traditional vibro sifter uses a bouncing ball to vibrate the screen to clean the sieve. This method is not as strong as the ultrasonic vibro sifter. One of the two blocks the blockage from the root cause, and the other can only be remedied afterwards.

Ultrasonic vibrating screen is especially suitable for sieving fine powder above 300 mesh and materials with light specific gravity. High-precision screening can be achieved, the screening accuracy can be increased by 1 to 70%, and the output can be increased by 0.5 to 10 times. Really solve the screening problem of strong adsorption, easy agglomeration, high static electricity, and light specific gravity materials. Digital signal input to realize automatic frequency tracking.

The traditional vibro sifter is suitable for a variety of industries, all kinds of materials, high efficiency, any powder, granules, mucus can be used. The range of requirements for material weight is wider.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.