Loading and unloading belt conveyors are versatile systems that find applications in various industries and settings where the efficient movement of goods between trucks, warehouses, and processing areas is essential. Some common applications of loading and unloading belt conveyors include:

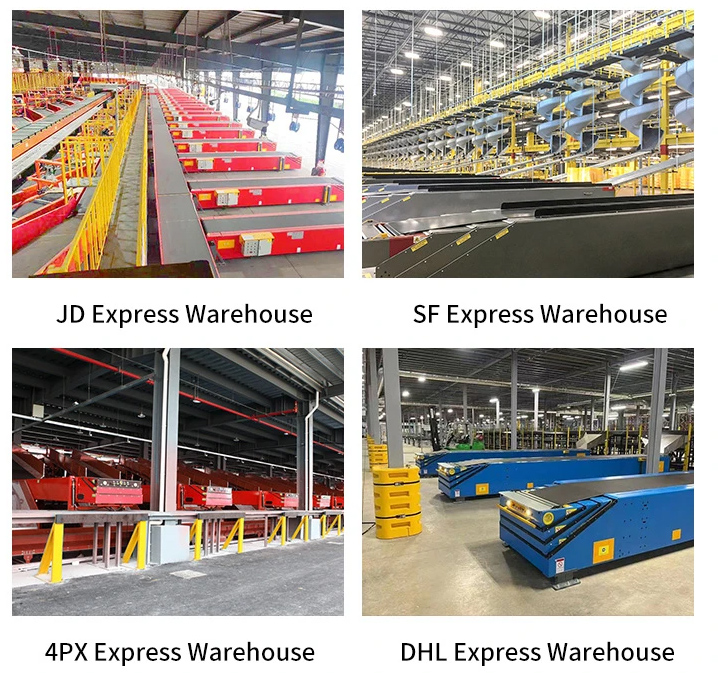

1.Warehousing and Distribution Centers: Loading and unloading belt conveyors are widely used in warehouses and distribution centers to streamline the movement of goods between trucks, storage areas, and shipping/receiving docks.

2.Logistics and Transportation: These conveyors play a crucial role in the logistics and transportation industry for loading and unloading trucks, trailers, and containers at distribution hubs, ports, and freight terminals.

3.Manufacturing Facilities: Loading and unloading belt conveyors are used in manufacturing plants to transfer raw materials, components, and finished products between production areas, storage facilities, and shipping docks.

4.Retail and E-commerce: In retail and e-commerce fulfillment centers, loading and unloading belt conveyors help expedite the handling of incoming and outgoing shipments, improving order processing and delivery times.

5.Food and Beverage Industry: Loading and unloading belt conveyors are utilized in food processing plants, breweries, and beverage facilities for transferring packaged goods, crates, and pallets between trucks and storage areas.

Using loading and unloading belt conveyors offers a variety of advantages across a variety of industries and applications. Here are some of the main advantages:

1. Efficiency and Productivity: Enables continuous material flow, minimizing downtime and increasing overall productivity.

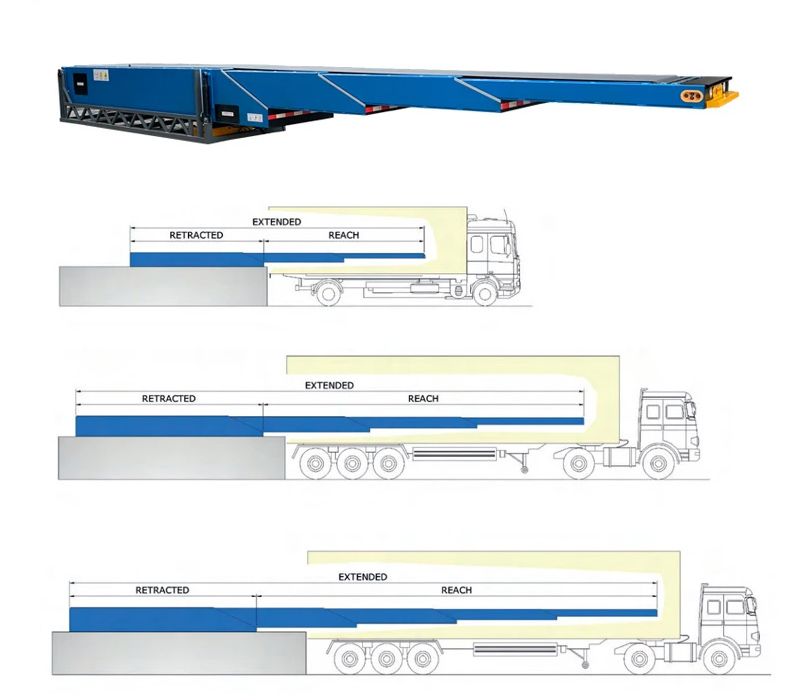

2. Versatility: Belt conveyors are versatile and can handle a variety of materials, including bulk materials, packaging, parts, and even irregularly shaped objects.

3. Space optimization: They can be designed to fit into narrow spaces and can be configured to transport materials vertically or around obstacles, eliminating the need for additional equipment or complex layouts.

4. Continuous operation: The loading and unloading belt conveyor can operate continuously to achieve stable flow of materials without interruption. This reduces the need for manual intervention and minimizes bottlenecks in production or logistics processes.

5. Cost savings: By automating the loading and unloading process, belt conveyors can save labor and operating expenses. They reduce the number of workers required for manual handling and minimize the risk of product damage during transportation.

These are just a few examples of the common applications of loading and unloading belt conveyors. Their versatility and ability to handle various types of goods make them indispensable in industries where the movement of materials and products is required.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.