Screw conveyors are commonly used in the chemical processing industry to transport bulk materials such as powders and granules. In the case of sodium carbonate powder, a screw conveyor can be used to transport the powder from one processing area to another, such as from a storage silo to a mixer or reactor vessel.This article will introduce the application of screw conveyor in sodium carbonate powder.

1. Conveying sodium carbonate powder to the mixer: Sodium carbonate powder is commonly used as a chemical reagent in various industrial applications. Screw conveyors can be used to convey powders from storage silos to mixers where they are combined with other materials to create a chemical reaction.

2. Delivery of sodium carbonate powder to the reaction vessel: In some applications, sodium carbonate powder can be used to neutralize acidic waste streams. Screw conveyors can be used to convey the powder from the storage silo to the reaction vessel where it mixes with the acid waste stream to neutralize it.

3. Transportation of sodium carbonate powder to packaging area: After processing and preparing sodium carbonate powder, it needs to be packaged for distribution. Screw conveyors can be used to convey powder from processing areas to packaging areas, ensuring a consistent and efficient supply of material.

4. Mix sodium carbonate powder with other materials: In some applications, sodium carbonate powder may need to be mixed with other materials before it can be used. Screw conveyors can be used to convey sodium carbonate powder to a mixer where it is mixed with other materials to create chemical reactions or new products.

The use of screw conveyors to transport sodium carbonate powder in the chemical industry has the following advantages:

Efficient and Reliable: Screw conveyors are known for their efficiency and reliability in transporting bulk materials. They can process large volumes of material at a consistent rate, making them ideal for applications that require a steady supply of material.

Gentle Handling: For gentle material handling, which is important when conveying fragile or friable materials such as sodium carbonate powder. The screw conveyor design allows material to move without damage or degradation, ensuring a high-quality end product.

Versatile: They can be designed to convey material horizontally, vertically or obliquely, and can be used to convey material over long distances.

Low Maintenance: Low maintenance and requires minimal maintenance. They are durable, reducing the need for frequent repairs or replacements.

Cost-effective: It is a cost-effective solution for transporting bulk materials such as sodium carbonate powder. They require minimal energy to operate and are relatively inexpensive compared to other delivery systems.

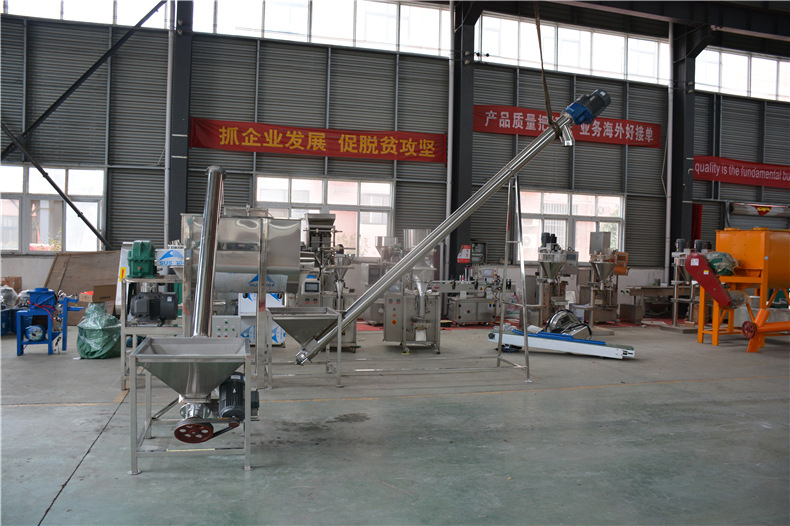

Here's an example of a customer case for a screw conveyor in the sodium carbonate powderindustry:

Here is a customer case of a screw conveyor conveying sodium carbonate powder:

Customer: A chemical manufacturing company was looking for a reliable and efficient way to transport sodium carbonate powder from a storage silo to a mixing vessel. They needed a conveying system that could handle a large volume of material at a consistent rate while al so being gentle on the powder to avoid degradation.

Solution: The company opted for a screw conveyor to transport the sodium carbonate powder. They chose a screw conveyor with a flexible design that could accommodate the specific needs of their application. The conveyor was designed to transport the powder horizontally over a d istance of 30 feet, with a capacity of 1,000 pounds per hour.

Results: The screw conveyor was installed and integrated into the company's existing processing equipment. The conveyor was able to transport the sodium carbonate powder at a consistent rate, ensuring a steady supply of material to the mixing vessel. The flexible design of the s crew conveyor allowed it to be easily adjusted to accommodate changes in the processing requirements.

The screw conveyor's gentle handling of the sodium carbonate powder ensured that the material was not damaged or degraded during transport. This helped to maintain the quality of the end product and reduced waste.

Overall, a screw conveyor is a versatile and efficient solution for transporting sodium carbonate powder in the chemical processing industry. It can be used to transport the powder to a mixer or reactor vessel, to a packaging area, or to a mixer for mixing with other materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.