Screw conveyors are commonly used in the pet flake industry to transport and handle materials such as PET flakes, which are small pieces of plastic produced by recycling PET bottles.

Material Handling: Screw conveyors are used to transport and handle PET flakes throughout the recycling process. They can be used to transport the flakes from one stage of the process to another, such as from the shredder to the washing line, or from the washing line to the drying stage.

Mixing and Blending: Screw conveyors can be used to mix and blend PET flakes with other materials, such as colorants or additives. The screw conveyor can ensure that the materials are thoroughly mixed and blended, ensuring a consistent product.

Metering and Feeding: Screw conveyors can be used to control the flow of PET flakes into a production line. They can be designed with various feed rates and accuracy levels to meet specific requirements, ensuring consistent production.

Extrusion: Screw conveyors are commonly used in the extrusion process to transport the PET flakes through the extruder. The screw conveyor can ensure that the flakes are evenly distributed and melted, ensuring a uniform product.

Packaging: Screw conveyors can be used to transport PET flakes to the packaging stage of the process. The screw conveyor can help to ensure that the flakes are transported efficiently and without contamination, ensuring a high-quality product.

Screw conveyors offer several advantages when used in the pet flake industry, including:

Efficient Material Conveying: For conveying a wide variety of materials, including PET flakes, with minimal wear. They can efficiently and consistently transport flakes throughout the recycling process, ensuring a high-quality product.

Minimal maintenance: relatively little maintenance, just regular cleaning and inspection. They have fewer moving parts than other types of conveyors, reducing the risk of failure and downtime.

EASY TO CLEAN: Can be designed with a smooth surface finish and minimal crevices, making it easy to clean and preventing the build-up of debris or contaminants. This is especially important in the pet flake industry where cleanliness is a top priority.

Customizable Design: Can be customized to meet specific requirements, including feed rate, flow rate and material handling capacity. They can be designed to handle the most challenging materials while minimizing wear, ensuring a long service life.

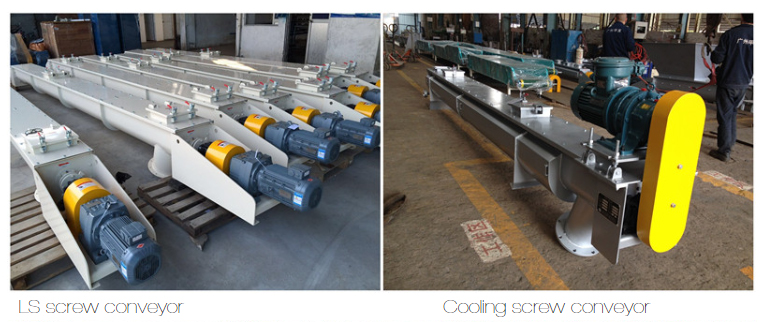

The following are examples of screw conveyors used in the pet flakes industry:

Customer case: European PET bottle flake recycling plant

A PET flake recycling plant in Europe uses screw conveyors in a variety of applications throughout the recycling process. The plant processes more than 10,000 tons of PET bottles per year, producing high-quality PET flakes for reuse.

An example of a screw conveyor application in a factory is the transport of PET flakes from the washing line to the drying stage. Screw conveyors are designed with custom feed rates and flow rates to ensure consistent delivery of flakes. The screw conveyor is also designed with a smooth surface finish and minimal crevices, making it easy to clean and preventing the build-up of debris or contaminants.

The plant also uses a screw conveyor at the packaging stage to transport the PET flakes to the packaging line. Screw conveyors are designed with custom flow and precision levels to ensure consistent packaging and minimize waste.

Overall, screw conveyors are a versatile and reliable solution for transporting and handling PET flakes in the recycling process. They can be customized to meet specific requirements and can be designed to handle even the most challenging materials with minimal wear and tear.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.