Magnetic powder is a kind of tiny particles with magnetism, and its main component is ferrite, which has excellent magnetic properties. Due to its strong adsorption capacity and controllability, magnetic powder is widely used in various fields, including the application in vibrating screens.

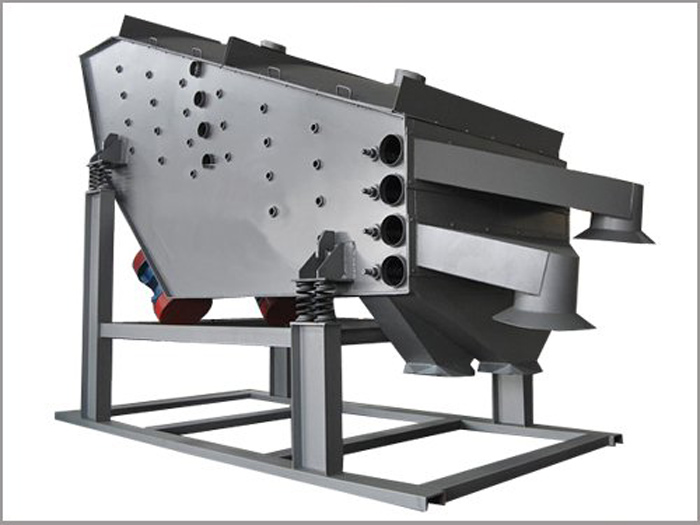

The vibrating screen is a commonly used solid material separation equipment, and its main working principle is to screen and separate materials through the vibration of the screen.

Adding magnetic powder into the vibrating screen can play the following roles:

1. Improve screening efficiency: Magnetic powder can be used as a screening aid in vibrating screens, which can effectively improve the screening efficiency of materials. When screening, the magnetic powder is adsorbed on the surface of the material, making the material form a magnetic cluster, increasing the density and adhesion of the material, so that it can pass through the screen more quickly and improve the screening efficiency.

2. Improve screening accuracy: Magnetic powder has a certain anti-adhesion ability in the vibrating screen, which can effectively prevent the solidification and blockage of materials during the screening process. By being adsorbed on the screen, the magnetic powder can fill the pores of the screen and prevent the material from escaping, so as to achieve the purpose of improving the screening accuracy.

3. Separation of magnetic materials: Some granular materials are magnetic, such as iron ore, magnetic ore, etc. By adding magnetic powder into the vibrating screen, the magnetic material can be adsorbed on the magnetic powder, and the effective separation of magnetic material can be realized. This separation method is more efficient and accurate than the traditional screening method.

4. Increase the use of screening: the application of magnetic powder in the vibrating screen can also be expanded according to needs. By adjusting the particle size and magnetic strength of the magnetic powder, it can have different adsorption and separation capabilities, so as to meet the screening needs of different occasions. At the same time, the magnetic powder can also be used in combination with other materials to further expand the application field of the vibrating screen.

5. Improve the wear resistance of the vibrating screen: During the long-term operation of the vibrating screen, it will be impacted and rubbed by the particles, which will cause the screen to wear. Adding magnetic powder in the screening process can reduce the direct contact between the particles and the screen, thereby reducing the wear of the screen.

In general, the application of magnetic powder in the vibrating screen can improve the screening efficiency and screening accuracy, realize the separation of magnetic materials, expand the screening application and improve the wear resistance of the vibrating screen. With the continuous development of technology, there is still room for further upgrading of the application of magnetic powder in vibrating screens, which is expected to bring more innovation and progress to the field of material separation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.