Screw conveyors provide an efficient and reliable method in lime powder transportation to transport lime powder from one location to another. Lime powder is a fine, dry powder that can be difficult to handle due to its tendency to dust and be abrasive. Screw conveyors can help overcome these challenges by providing a controlled and enclosed environment for the material to be transported.

There are several advantages to using a screw conveyor to transport lime powder. Here are some key advantages:

Efficient Transport: Screw conveyors are an efficient and cost-effective method of transporting lime powder from one location to another, screw conveyors can be customized to meet the specific requirements of the application, including required flow rates and distances covered .

Minimal dust emission: Lime powder generates dust during transportation, which poses a health and safety hazard. Screw conveyors can be designed as closed enclosures to minimize dust emissions and create a safer and healthier working environment for the operator.

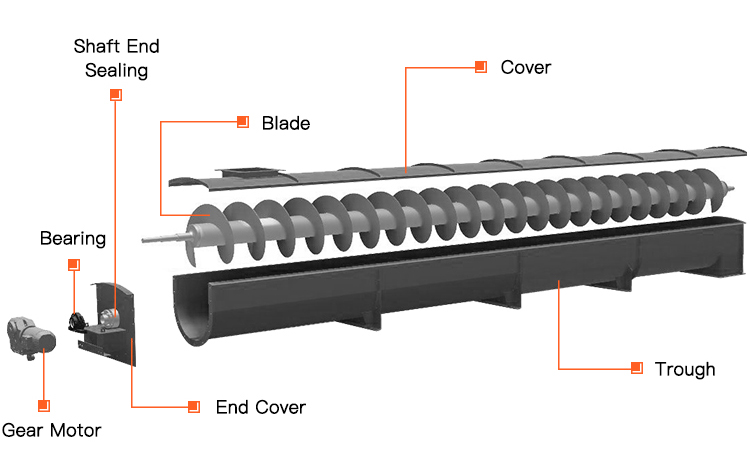

Construction of specific materials: Lime powder is abrasive and may cause wear on conveyor systems. Screw conveyors can be constructed with material-specific construction, such as using wear-resistant materials, to address the abrasive nature of the material and extend the life of the conveyor.

Consistent and Accurate Feed Rate: The screw conveyor can be equipped with a batching system to ensure consistent and accurate lime powder feed rate. This helps ensure that lime powder is added to the process at the correct rate, resulting in a consistent end product.

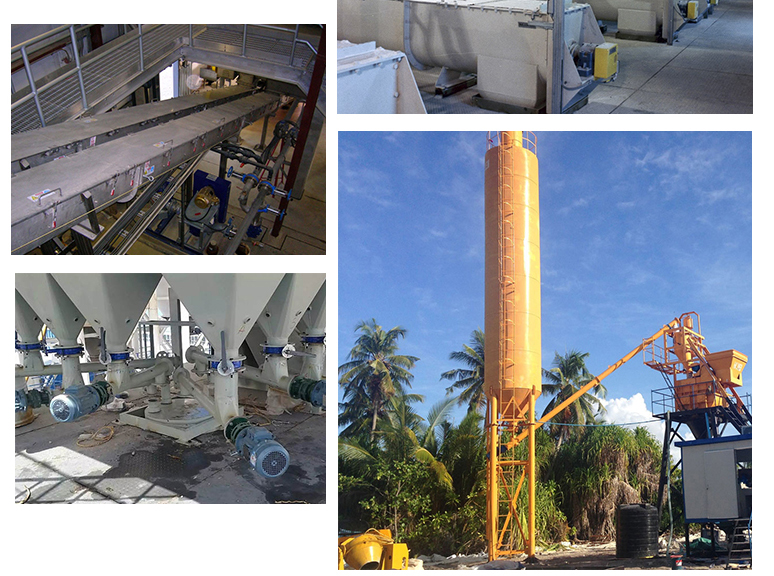

Flexible configuration: The screw conveyor can be configured in a variety of ways to suit the layout and requirements of the processing system. They can be designed horizontally, inclined or vertically, depending on the space available and the required material flow.

Some considerations for the application of lime powder in a screw conveyor include:

Material characteristics: Lime powder can be abrasive and can create dust, which can pose a health hazard if inhaled. The screw conveyor system should be designed with material-specific construction to handle the abrasive nature of the material and minimize dust emissions.

Contamination prevention: Lime powder can react with other materials, so it is important to prevent cross-contamination between batches. The screw conveyor system should be designed with easy cleaning and maintenance in mind to prevent contamination.

Flow rate and accuracy: The flow rate and accuracy of the lime powder feed are critical to the success of the process. The screw conveyor system should be designed with adjustable speed and dosing systems to ensure a consistent and accurate feed rate.

System configuration: The screw conveyor system can be configured in various ways, including horizontal, inclined, or vertical, depending on the requirements of the application and the space available.

In summary, screw conveyors can be used to transport lime powder in various applications, including in agriculture and industrial settings. Proper design and construction are critical to ensure efficient and safe operation, prevent cross-contamination, and achieve a consistent and accurate feed rate.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.